Supercharged Servo Presses

November 25, 2024 Tennessee metal former Quality Metal Stamping has welcomed three servo presses to its operations in the last few years, enjoying dramatically increased productivity gains and a reduction in tool-maintenance costs. And, it’s taken the next step, by training its team in the intricacies of fine-tuning servo performance.

Quality Metal Stamping (QMS) operates a recently expanded production facility in Henderson, TN. The firm houses 18 coil-fed stamping presses, as well as an array of equipment for laser cutting, bending, welding and powder coating.

Integrating fabrication processes into its stamping operations has enabled QMS to grow its ability not only to produce low- and high-volume stampings, but also to take on prototype development and short-run projects, and then in many cases move those projects over to its bread-and-butter stamping operations. Its pressroom, the focus here, boasts press capacities from 40 to 300 tons and features three relatively new servo presses—two 200-ton models (one straightside and one gap-frame) and a 150-ton gap-frame press.

Integrating fabrication processes into its stamping operations has enabled QMS to grow its ability not only to produce low- and high-volume stampings, but also to take on prototype development and short-run projects, and then in many cases move those projects over to its bread-and-butter stamping operations. Its pressroom, the focus here, boasts press capacities from 40 to 300 tons and features three relatively new servo presses—two 200-ton models (one straightside and one gap-frame) and a 150-ton gap-frame press.

“I don’t think we’ll ever go back to purchasing conventional mechanical presses,” says Colin Serling, QMS’ vice president of strategy, who joined brother Steve Serling, vice president of operations and production, in a conversation with MetalForming.

“The new servo presses (the latest a 200-ton Aida that hit the floor in 2022) make our business more efficient, along with improving die life and reducing downtime,” Colin adds.

Continuous Learning

Contributing to the success of its new servo presses: having QMS operators and engineers attend the Aida-America Servo Symposium, which typically welcomes more than 100 guests from dozens of companies to Aida-America headquarters in Dayton, OH. There they participate in educational seminars and witness hands-on servo-technology demonstrations.

“We’ve sent operators and engineers to the last two symposiums,” Steve says, “and they always come back to QMS with a lot of energy and enthusiasm to seek ways to continuously improve press performance and productivity. On three different tools, for example, the team was able to increase stroke rate, and reduce tool wear and subsequent maintenance costs, all less than 3 weeks after having attended the symposium. That’s a testament to Aida and to our young talent and how they’re partnering.”

DSF-C1-2000A Single-Point Gap-Frame Servo Press

- Capacity: 220 U.S. tons; rated tonnage 0.236 in. above bottom dead center

- Stroke length: 9.84 in. max at 50 strokes/min. (full revolution)

- Pendulum motion: 7.9 in. at 60 strokes/min; 6.3 in. at 70 strokes/min.; 4.3 in. at 86 strokes/min.

- Bolster area: 48.8 by 33.1 in.

- Throat depth: 16.9 in.

DSF-N2-2000A Two-Point Straightside Servo Press

- Capacity: 220 U.S. tons; rated tonnage 0.276 in. above bottom dead center

- Stroke length: 9.84 in. max at 50 strokes/min. (full revolution)

- Pendulum motion: 4.92 in. at 75 strokes/min; 3.94 in. at 82 strokes/min.; 2.95 in. at 92 strokes/min.; 1.97 in. at 105 strokes/min.

- Bolster area: 84.6 by 33.1 in.

|

Such improvements have allowed QMS to deliver its message to a broader customer base, the brothers share. Always strong in the metal-construction and electrical-products industries, QMS recently has enjoyed success gaining work in the HVAC and solar markets.

“The speed of the servo presses, along with our newly expanded metal-fabrication operations, have gotten us in the door with some big OEMs in those sectors,” says Colin. “They, along with our other OEM customers, increasingly look for vertically integrated one-stop shops that can prototype, fabricate and provide high-volume stamping—our diverse set of capabilities has become a differentiator for us.”

Growth Requires Attention to Hiring and Retention

A glut of new customers has brought growth in every measure imaginable, including revenue and headcount (the facility now employs more than 100), including building out a strong second shift of production. “We’ve gotten younger as well,” Steve says, noting that the firm recently has hired several young engineers and toolmakers.

“We have a great relationship with the local high schools and technical schools,” he explains. Credit, he says, goes to the firm’s human resources manager Heather Griffin, on board at QMS for 2 yr. “Heather previously worked at the local high school,” Steve shares, “and has been instrumental in helping us attract young talent to the company.”

Equally as important as this newly developed talent pipeline is a strategy to retain good employees, thanks in part to the firm’s work-based learning program, which includes the opportunity for newly trained employees to program and operate the new servo presses.

“The key is flexibility,” Colin explains: “giving new hires opportunities to try different machines and roles at the company, to find their niche. At the same time, our senior employees do a great job taking younger employees under their wings; they seem to be energized by the opportunity to serve as mentors.”

A Critical Role in Developing New Stamping Technology

In the pressroom in particular, Steve credits the Allen-Bradley press controls on the Aida servo presses for their user friendliness, a characteristic not lost on new hires. And, even experienced operators at QMS can use the controls to streamline programming and bring new jobs onboard in a timely manner.

“New operators can learn to run those presses in 2 weeks or less,” he says, “a testament to Aida’s engineering knowhow.”

Aida-America formed its partnership with Rockwell to develop fully integrated Rockwell Allen-Bradley control packages for the North American market in 2018. The fully integrated packages then were brought to market in 2020, first for the single-point gap-frame series, and then in 2021 for two-point straightside presses.

QMS jumped on board as an early adopter of the new technology package by first installing a single-point gap-frame servo press (a model DSF-C1-A-2000) in 2021, and then installing a two-point straightside (model DSF-N2-2000-AB) in 2022.

“QMS was a key partner of Aida and Rockwell in fine-tuning and further developing the features of the control in a real-world stamping environment,” shares Bob Southwell, Aida-America vice president. “This included working directly with control and application engineers to optimize press performance and part quality, and maximize machine uptime and production rate.”

The ROI Equation

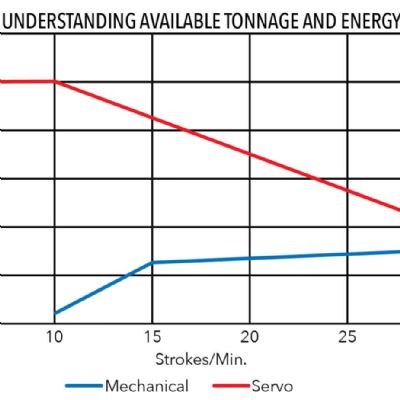

The lower-tonnage presses fit perfectly with the material and job mix at QMS, as 100 to 300 tons is the sweet spot and brings ample demand from the market, says Colin. “However, a 400-ton servo press is on our radar at some point,” he shares. “We’ve seen a quick return on investment (ROI), as we’ve been able to increase the stroke rate on some of our dies from 45 strokes/min. on a conventional mechanical press to as high as 90 to 100 strokes/min. on the servos.”

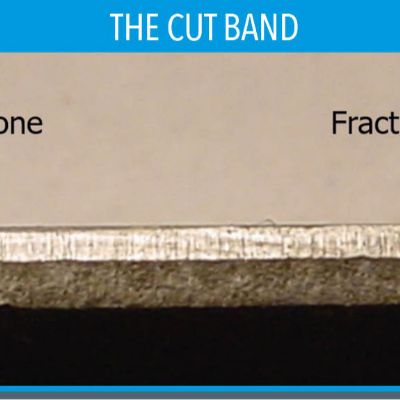

Contributing to the rapid ROI of the new presses is less tool wear, thus reduced time and costs for tool maintenance. “We’ve been able to reevaluate the preventive-maintenance (PM) schedules on the tools we run on the servo presses, which tend to be our highest runners,” says Steve, crediting the ability to slow the impact speed at bottom dead center and minimize snapthrough tonnage. “With a typical 250,000-hit production run, on a conventional press we perform PM after every run; now we typically can perform PM on the tools after every two runs, or 500,000 hits.”

Much of the work run on the 200-ton gap-frame servo press comprises 0.030- to 0.036-in.-thick galvanized Grade 50 steel, in addition to a bit of 0.024-in.-thick Type 304 stainless steel. Running through the 200-ton straightside: 14- and 12-gauge galvanized Grade 55 steel. The two presses sit side by side on the pressroom floor; 75% of their capacity is consumed by one product line or assembly for the metal-construction market, comprising 15 different part designs running on eight unique dies per press.

And, what about the third and oldest servo press in the shop, the 150-ton model? It processes a wide variety of parts, explains Steve, that tend to be shorter runs of 30,000-40,000 parts for the HVAC, electrical-transformer and other industries. The material mix here includes 0.019-in.-thick stainless steel and 10-gauge hot-rolled Grade 50 high-strength low-alloy steel.

“We have to be globally competitive, and servo press technology enables that,” Steve concludes. “And, we understand the need to attract and keep young and passionate minds into the company at all levels, and that’s made possible in part by using the newest and most current technology.” MF

See also: Aida-America Corp.

Technologies: Stamping Presses

Integrating fabrication processes into its stamping operations has enabled QMS to grow its ability not only to produce low- and high-volume stampings, but also to take on prototype development and short-run projects, and then in many cases move those projects over to its bread-and-butter stamping operations. Its pressroom, the focus here, boasts press capacities from 40 to 300 tons and features three relatively new servo presses—two 200-ton models (one straightside and one gap-frame) and a 150-ton gap-frame press.

Integrating fabrication processes into its stamping operations has enabled QMS to grow its ability not only to produce low- and high-volume stampings, but also to take on prototype development and short-run projects, and then in many cases move those projects over to its bread-and-butter stamping operations. Its pressroom, the focus here, boasts press capacities from 40 to 300 tons and features three relatively new servo presses—two 200-ton models (one straightside and one gap-frame) and a 150-ton gap-frame press.