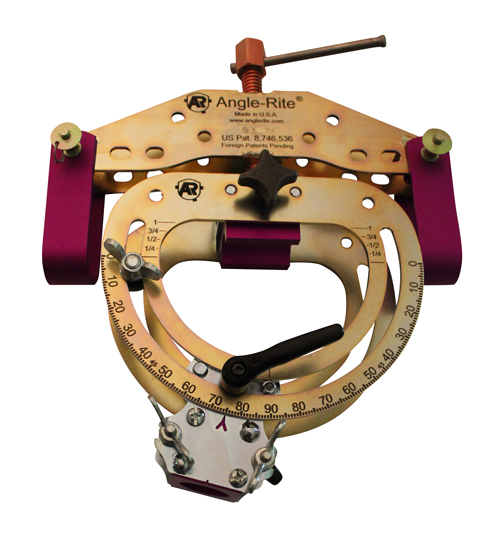

Tube- and Pipe-Welding Clamping System

October 1, 2017Comments

Booth B37070

Meridian will show its Angle-Rite tube- and pipe-welding clamping system, which compensates for weld-stress distortion while simplifying the welding process for tube and pipe joints, from setup to completion. The system consists of a primary clamp that pre-bends the intersected tube prior to welding. The secondary clamp holds the intersecting tube or pipe in a precise angle to be miter cut using the reciprocating-saw attachment, or notched using the abrasive or hole-saw notcher. Once cut, the secondary clamp holding its tube or pipe is rejoined with the primary clamp and its attached tube or pipe.

Angle and rotational alignment of the tubes or pipes are retained throughout the entire process. By clamping the primary and intersecting tube or pipe in place, the welder can weld the joint. The primary clamp’s bending force compensates for weld-stress distortion during welding.