Servo-Driven In-Die-Tapping Technology

August 4, 2021Comments

Hutchison Tool Sales

Booth D46653

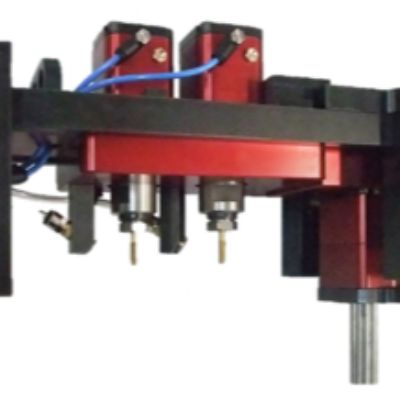

Hutchison Tool sales is exhibiting servo-driven

in-die-tapping technology, with the tapping heads available in standard units

for flat-running/minimal-strip-lift parts as well as in follow-along units for

parts with complex forming/high-lift characteristics. Both the standard and

follow-along units come in a choice of high-speed/low-torque or

low-speed/high-torque motors depending on application requirements.

Hutchison Tool sales is exhibiting servo-driven

in-die-tapping technology, with the tapping heads available in standard units

for flat-running/minimal-strip-lift parts as well as in follow-along units for

parts with complex forming/high-lift characteristics. Both the standard and

follow-along units come in a choice of high-speed/low-torque or

low-speed/high-torque motors depending on application requirements.

The servo-driven in-die-tapping controllers allow for the running of multiple tapping heads from one controller. In addition, the controller can store a multitude of programs with simple access when changing from one job to another. The user-friendly control panel simplifies programming of tap rpm, tap travel and press-feed-angle requirements.

And, the servo controller also can monitor tapping torque to monitor thread quality of tapped holes, and is password-protected for different levels of operator, supervisor and engineering access. Also, remote internet access is available for downloading data or remote troubleshooting.

See also: Hutchison Tool Sales Co.

Technologies: In-Die Operations

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. In-Die Operations

In-Die OperationsUnits for In-Die Tapping and Insertion

Wednesday, July 2, 2025

In-Die Operations

In-Die OperationsIn-Die Tapping

Wednesday, October 2, 2019

In-Die Operations

In-Die OperationsTools for Tapping

Wednesday, October 2, 2019