The OPC (or other software) may need to calibrate the data to match the machine’s own values. For example, an amperage sensor will output a value of 0 to 4095; that value must be calibrated to match the machine’s motor speed or tooling force. From there, the information can feed into a metal former’s enterprise resource planning (ERP) or manufacturing execution system (MES) software, which in turn can populate real-time reports with the data.

The ERP or MES software can maintain current and historical data, enabling managers to analyze the information with respect to quality, efficiency and other key metrics. A few ways that manufacturers can use the data:

- Collect information for end-of-shift reporting, to help, for example, determine if the material consumed coincides with the number of parts produced.

- Track counts in a work center to assist in production planning.

- Match work orders to what’s running in the machines, to update inventory consumption.

- Compare the number of machine cycles completed to the number of parts produced, to track scrap production.

- Gauge workcenter downtime.

- Look for out-of-limit processes, to support quality control.

Real-Time Production/Process Monitoring

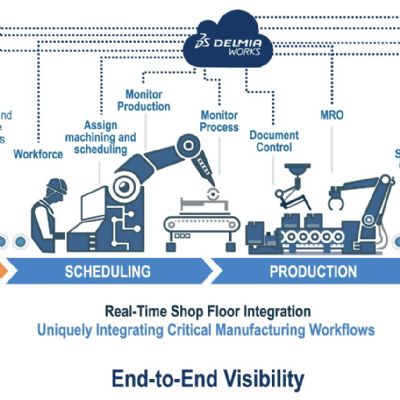

While historical information plays a valuable role, the most powerful use of sensors on the shop floor comes from combining the real-time data generated via real-time production and process monitoring with a manufacturer’s MES and ERP systems.

At a base level, real-time production monitoring helps to bring meaning to the counts from sensors. In many cases, a production cycle can take mere milliseconds, so metal formers can use production monitoring to capture data based on cycles and then display the information as an average, such as X amount of product/min. or hr. Counts in ERP and MES also support automated workflows, such as material orders, inventory updates, production scheduling, and other shop-floor and accounting processes.

When combined with statistical analysis, real-time production and process monitoring can help metal formers establish parameters for performance, wear, etc. From there, the software can track and flag any production cycles and processes measured by machine sensors that wander outside of an acceptable range. Additionally, MES software can use the data to make decisions about scheduling production, preventive maintenance and other operations.

The actual metrics or key performance indicators (KPIs) that a metal former tracks will be specific to the company’s business priorities. Here we list a few common KPIs that will help optimize operations.

- Throughput. Monitoring may reveal that, when running the same job in two different machines, one machine outperforms the other. With these insights, a metal former can decide to schedule a more time-sensitive work order on the better-running machine and delegate another job to the slower machine.

- Downtime. Downtime monitoring and analysis help sort out scheduled breaks, such as 30 min. of downtime during lunch periods, versus required breaks due, for example, to the need to replenish lubricant supplies. And, the ability to monitor changes in vibration, for example, can provide an early indicator of wear that requires predictive maintenance before it creates a downtime issue.

- Rate of rejected parts. Comparing machine amperage to the number of rejected parts coming from the machine can help provide insight into whether a job is improperly set up, or if there are actual issues with the machine affecting quality.

- Rate of material consumption. Monitoring material consumption in real time can help metal formers keep accurate, up-to-date records of inventories to facilitate purchasing decisions and production planning.

- Lubricant level. Monitoring flow can alert metal formers as to when to replenish supplies before impacting product quality.

While metal formers can track a nearly unlimited number of KPIs with sensors and real-time production and process monitoring, starting with too many KPIs can ground monitoring and analysis initiatives to a halt. So, managers must prioritize establishing a very short list of KPIs most relevant to the business. Then, having regularly been tracking metrics against these KPIs, the company can look at incrementally adding new KPIs.

Ensuring a Successful Start

Metal formers can take several steps to help ensure success with IIoT implementation on legacy equipment. Most important: Start with one machine. We have seen many companies get so excited about monitoring their shop floors that they set up sensors on several machines at once. Then they come back and say, “Well this isn’t working the way we thought it would.”

The most successful companies start with one machine, get the sensors and monitoring working, and start collecting sample information that everyone agrees is vital and important to that machine. Once the data start flowing and resulting information meets the team’s needs, the team then can apply the approach to other machines.

Be smart when selecting that initial machine; don’t pick the most challenging one. Instead, start the IIoT journey on a machine where the team understands how the interface works and readily can install the sensors. Even if getting up and running proves simple, the team still will learn things through the process. This knowledge will help with the rest of the installations and give the team confidence that the results meet expectations.

In addition, avoid the temptation to start running production or process monitoring on a machine that isn’t performing as well as other machinery; it won’t provide the right answers and usually leads to having to go back and restart the process. Instead, look to connect sensors and monitoring to a well-operating machine from which the team can collect data and create a baseline of understanding. This will provide a springboard from which to measure other machines.

When first monitoring data from the sensors, remember that sensors placed on different parts of a machine often will produce different results, even when using the same type of sensor. For example, the amperage read from a meter at a machine’s incoming power source will differ from that read from a secondary, downstream amperage meter.

Also, consider some physical implementation factors. In most cases, metal formers can rely on their inhouse maintenance teams—familiar with their equipment, machines and the building—for installs, as opposed to outside electricians. Additionally, consider using wired connections to each machine rather than wireless, to avoid connectivity issues on the shop floor. And, plan for the future by installing network drops at every machine, providing network capacity to all machines as the team expands the installation of sensors across the shop floor.

By following the best practices outlined here for bringing sensors and real-time monitoring to existing machinery, even metal formers just starting out quickly can gain insights to improve efficiency, ultimately realizing savings and profits. MF

Lynn Loughmiller is a senior automation engineer and Neil Gow is director of manufacturing within the DelmiaWorks manufacturing ERP team of Dassault Systèmes.

See also: Dassault Systemes

Technologies: Management

Available sensors on the market support different types of data collection that enable manufacturers to track various metrics related to productivity, consumption and wear, among other factors. Sensors commonly used by metal formers:

Available sensors on the market support different types of data collection that enable manufacturers to track various metrics related to productivity, consumption and wear, among other factors. Sensors commonly used by metal formers: