Smart-Factory Suite Provides Machine Monitoring and Planning

January 4, 2023Comments

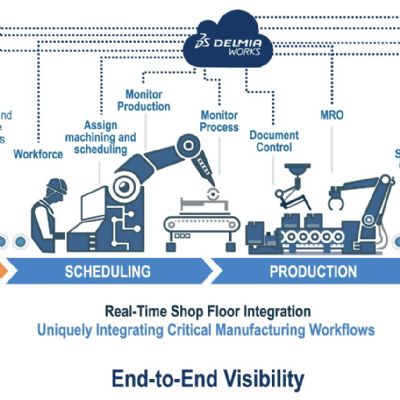

InFocus Scheduling from R.E.R. Software, Inc. offers computer-aided scheduling for all shop machine assets—for tool-build machining and other manufacturing processes—through its AutoTrack, AutoPlan and Smart Alert capabilities. Employ InFocus as a standalone system for shop machines, or tie it in to your operation’s MES/ERP systems.

InFocus Scheduling from R.E.R. Software, Inc. offers computer-aided scheduling for all shop machine assets—for tool-build machining and other manufacturing processes—through its AutoTrack, AutoPlan and Smart Alert capabilities. Employ InFocus as a standalone system for shop machines, or tie it in to your operation’s MES/ERP systems.

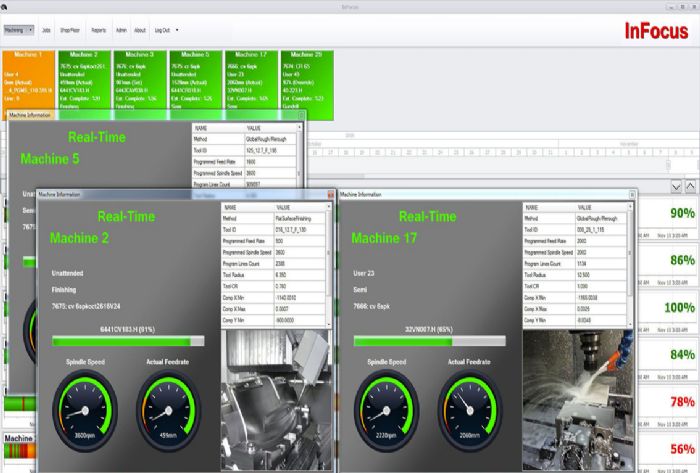

Use the AutoTrack machine-monitoring platform (screenshot pictured) to track every machine and an unlimited number of data points in real time, and study historical information via the platform’s dynamic reporting functionality. Its automated job-tracking and operations-analysis component allows for visibility into job processing durations, job costing, tool-usage analysis, maintenance and machining methods, and more.

AutoPlan allows users to align jobs and understand when a project will be ready for each department while ensuring the correct order of work to meet job due dates. This platform performs these duties while ensuring that machine resources do not remain idle. For example, its process-flow functions include display color coordination to show the overall status of all tasks visually—completed, started, late, etc. Its simple-to-use interface enables mouse click/drag, zoom in/out, delete, re-link and creation of tasks to adjust the expected flow of each job.

And, SmartAlert, a dynamic notification system, provides notifications via email or text tailored to individual requirements while providing the backbone of predictive maintenance in the InFocus smart-factory suite.

See also: R.E.R. Software, Inc.

Technologies: Management