Desktop Metal Qualifies Type 4140 Steel for High-Volume AM

June 7, 2021Comments

Desktop Metal announced that it has qualified the use of 4140 low-alloy steel for its Production System additive manufacturing (AM) platform, which leverages the company’s Single Pass Jetting (SPJ) technology. Desktop Metal reports to be the first and only company to qualify 4140 low-alloy steel for use with metal binder jetting systems, enabling its use in mass production end-use part applications.

Desktop Metal announced that it has qualified the use of 4140 low-alloy steel for its Production System additive manufacturing (AM) platform, which leverages the company’s Single Pass Jetting (SPJ) technology. Desktop Metal reports to be the first and only company to qualify 4140 low-alloy steel for use with metal binder jetting systems, enabling its use in mass production end-use part applications.

A versatile low-alloy steels, 4140 provides toughness, high tensile strength, and abrasion and impact resistance. The all-purpose, heat-treatable steel finds use in a variety of automotive, oil and gas, and industrial applications, such as gears, downhole tool components, couplings, spindles, bolts and nuts, and other mechanical parts.

“4140 has been a challenging material for metal binder jetting because of its low-alloyed content, tight carbon-control requirements, and low ignition energy, which together require advanced binder chemistry, as well as extensive printing and sintering optimization and atmospheric controls for safe processing,” says Jonah Myerberg, co-founder and chief technical officer of Desktop Metal. “With the speed of the Production System, businesses can now use binder jetting to print complex 4140 parts at competitive costs while maintaining the strength and mechanical properties of traditionally manufactured alternatives. This is a game-changing solution for manufacturers who have been tied to time-consuming and expensive machining and conventional tool-based manufacturing processes.”

Desktop Metal’s materials science team has validated that 4140 low-alloy steel printed on Production System technology and sintered by Desktop Metal meets MPIF 35 standards for structural powder metallurgy parts set by the Metal Powder Industries Federation.

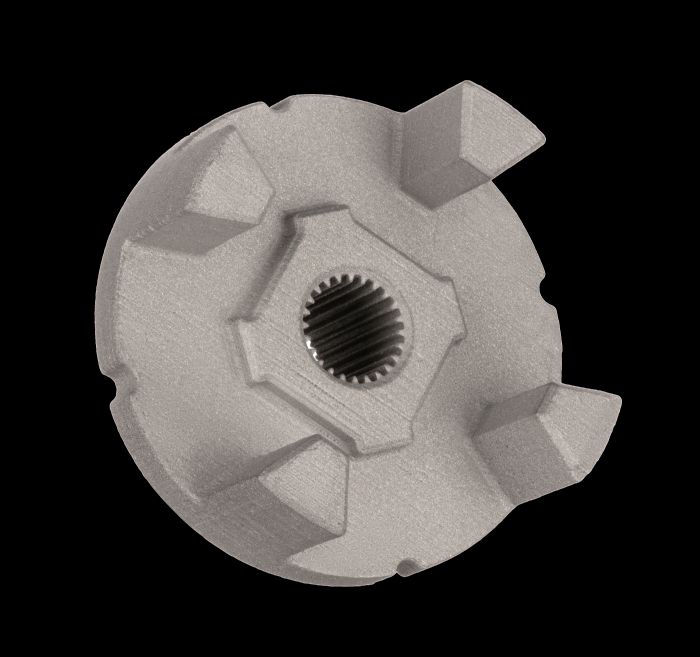

Successful 4140 applications offered by Desktop Metal include a power-steering joint (pictured) used for power transfer between an electric power steering motor and the steering shaft in an automobile. The 4140 material provides needed strength and hardness for the spline teeth that connect this part to the rest of its assembly. While production using a conventional press and sinter process would require a costly mold, the Production System P-50, a mass-production system for end-use parts that’s scheduled for commercial shipments beginning in the second half of 2021, enables production with no tooling, reducing lead times and enabling more flexible design for quantities to 1.2 million annually at a fully burdened part cost as low as $2.45, according to Desktop Metal officials.

Other successful applications reported by the company: herringbone gears, linear pneumatic pistons and lever drives for adjusting the locations of machine components.

View Glossary of Metalforming Terms

See also: Desktop Metal, Inc.

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementDriving Progress: Xometry's 2024 Automotive Manufacturing In...

Thursday, May 2, 2024

Welding and Joining

Welding and JoiningMiller Electric Introduces OptX 2-kW Handheld Fiber Laser We...

Wednesday, May 1, 2024