Miller Electric Introduces OptX 2-kW Handheld Fiber Laser Welder

May 1, 2024Comments

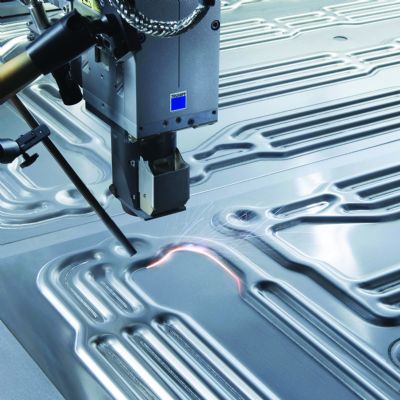

Miller Electric Mfg., Appleton, WI, introduces the OptX 2-kW handheld fiber laser welding machine, promising to increase operating speeds by as much as five times compared to more conventional welding processes. The machine’s speed stems from its laser-sharp focus, say company officials, which penetrates workpieces quickly and with a narrow beam.

Miller Electric Mfg., Appleton, WI, introduces the OptX 2-kW handheld fiber laser welding machine, promising to increase operating speeds by as much as five times compared to more conventional welding processes. The machine’s speed stems from its laser-sharp focus, say company officials, which penetrates workpieces quickly and with a narrow beam.

Miller developed the OptX 2-kW machine in collaboration with IPG Photonics Corp. “The alliance advances laser technologies for the handheld welding market,” says Dave Lambert, Miller Electric group president of sales and marketing. He notes these machine benefits: reduced heat input; no weld puddle; and less pre- and post-weld processing, such as deburring.

Among key differences welders will notice, when compared to conventional welding processes:

- Instead of leaning directly over the weld, welders must lean back or to the side.

- The welding machine “pushes” the weld, directing some of the movement.

- Laser heat is provided by focused light energy, compared to the electrical resistance in arc welding.

- Laser heat is highly focused versus the dispersed heat in arc welding.

- The workpiece is heated from within, starting at the focal point and spreading outward, rather than being heated from the surface and the heat being absorbed into the part.

- Due to the internal reinforcement of laser welding, laser-welded joints exhibit less distortion than arc-welded joints because the external reinforcement creates torque or external pulling forces on the weldment.

Company officials note that the best applications for the machine include precision weldments with tight fitup and minimal gaps, where metal formers seek high productivity but cannot automate the process. The machine can weld nearly all metal alloys, in sheet and plate to 5/16 in. thick, including highly reflective materials, aluminum alloys, titanium, brass, copper, steel and stainless steel alloys, and galvanized material. And it can weld dissimilar alloys such as stainless steel to copper.