Huge Lead-Time and Cost Cuts for Stainless-Steel Fuel-Injector Nozzles

November 30, 2021Comments

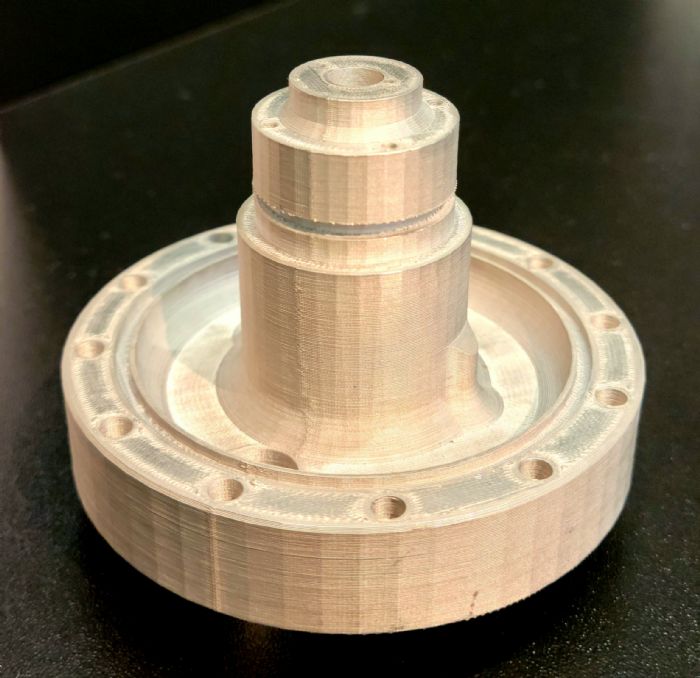

At Formnext…Markforged displayed this diesel-fuel-injector adapter, made from 17-4 PH stainless steel in the company’s Metal X additive manufacturing (AM) machine. Previously, to produce this next-generation component, Sandia National Labs outsourced laser sintering and CNC machining. Use of the Metal X, according to Markforged officials, allows Sandia to perform in-source AM with only a simple post-machining step. This reduces lead time from months to less than 5 days, with material and process costs reduced from thousands of dollars to less than $200.

At Formnext…Markforged displayed this diesel-fuel-injector adapter, made from 17-4 PH stainless steel in the company’s Metal X additive manufacturing (AM) machine. Previously, to produce this next-generation component, Sandia National Labs outsourced laser sintering and CNC machining. Use of the Metal X, according to Markforged officials, allows Sandia to perform in-source AM with only a simple post-machining step. This reduces lead time from months to less than 5 days, with material and process costs reduced from thousands of dollars to less than $200.

Industry-Related Terms: CNC (Computer Numerical Control), LASER, Lead Time, Stainless Steel

View Glossary of Metalforming Terms

View Glossary of Metalforming Terms

See also: Markforged

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingWaterjet Optimizes Accuracy, Minimizes Taper

Thursday, July 3, 2025

In-Die Operations

In-Die OperationsUnits for In-Die Tapping and Insertion

Wednesday, July 2, 2025