Successful Metal-AM Builds Are No Accident: The Value of In-Process Metrology

November 11, 2020Comments

If you can’t measure it, you can’t control it—and controlling as much of the 3D-printing process as possible directly relates to end-product quality. But what exactly should manufacturers measure during a metal-AM build, and how? And in what ways can companies leverage metrology technology to ensure that they produce perfect, in-spec parts?

Here we’ll discuss three key metrics to help ensure successful metal-AM production: meltpool status, atmospheric composition and powder-bed height.

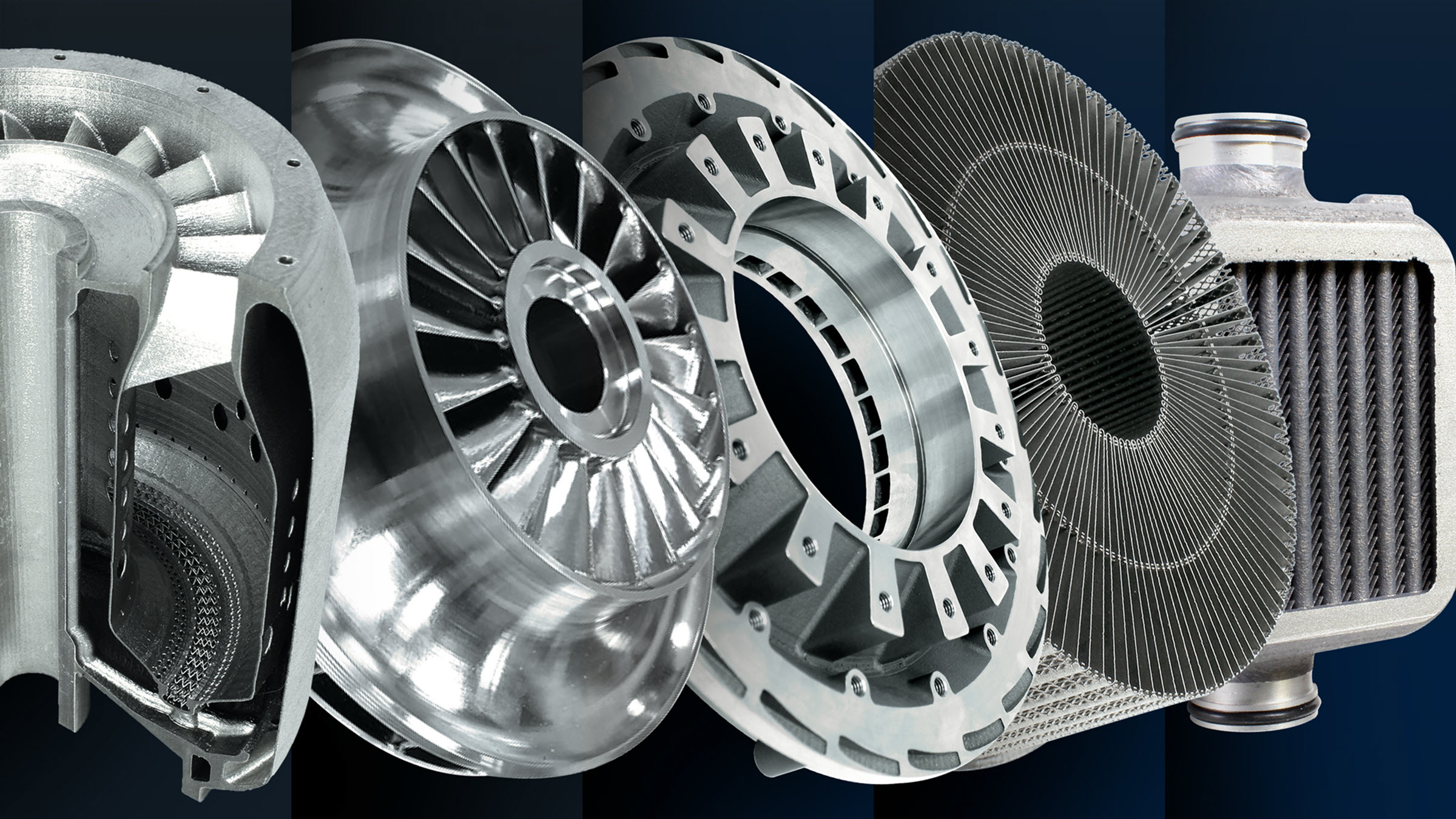

A series of 3D-printed mission-critical parts for industrial applications, from left to right: cross-section of a small engine, super-critical CO2 impeller, microturbine component and two types of heat exchangers.

Monitoring the Meltpool

As metal-AM powder transforms to solid metal in the build chamber, a lot can happen to affect the quality of the base material. Excess laser energy can cause the material to vaporize, while too little energy results in unmelted powder. Both scenarios can lead to porosity and negatively impact the mechanical integrity of the printed parts.

Meltpool monitoring of the active micro-welding area, where the laser meets the powder, can gather data related to the laser beam, the temperature of the liquid metal and even the surface tension of the meltpool. When detecting anomalies outside of control limits, the AM machine can alert the operator to interrupt a build and change settings, or even stop the build completely. Some systems rely on a photodiode for these measurements, while others incorporate mirrors and a high-resolution camera for optimal performance.

Next-generation AM systems go beyond just reporting such data by providing integrated, in-situ process metrology to detect individual meltpool instabilities. They then can enable closed-loop energy adjustments in real time during the build. Then, during post-production, correlating in-system metrology data with part outcomes can help identify probabilities of porosity for any given region in a part.

Analyzing the Atmosphere

When manufacturers print metal parts at very high temperatures in a less-than-perfect build-chamber environment, any unwanted atoms or molecules in the atmosphere can become incorporated into the material as it solidifies. Oxygen in the chamber can lead to oxidation, causing pores to occur in the build material. Hydrogen can react with and embrittle the metal. And, humidity of any kind must be monitored, because metal powder acts like a desiccant and will absorb water vapor. Moisture absorbed by the powder bed will be ionized when the laser hits it, leading to other complications in addition to oxidation.

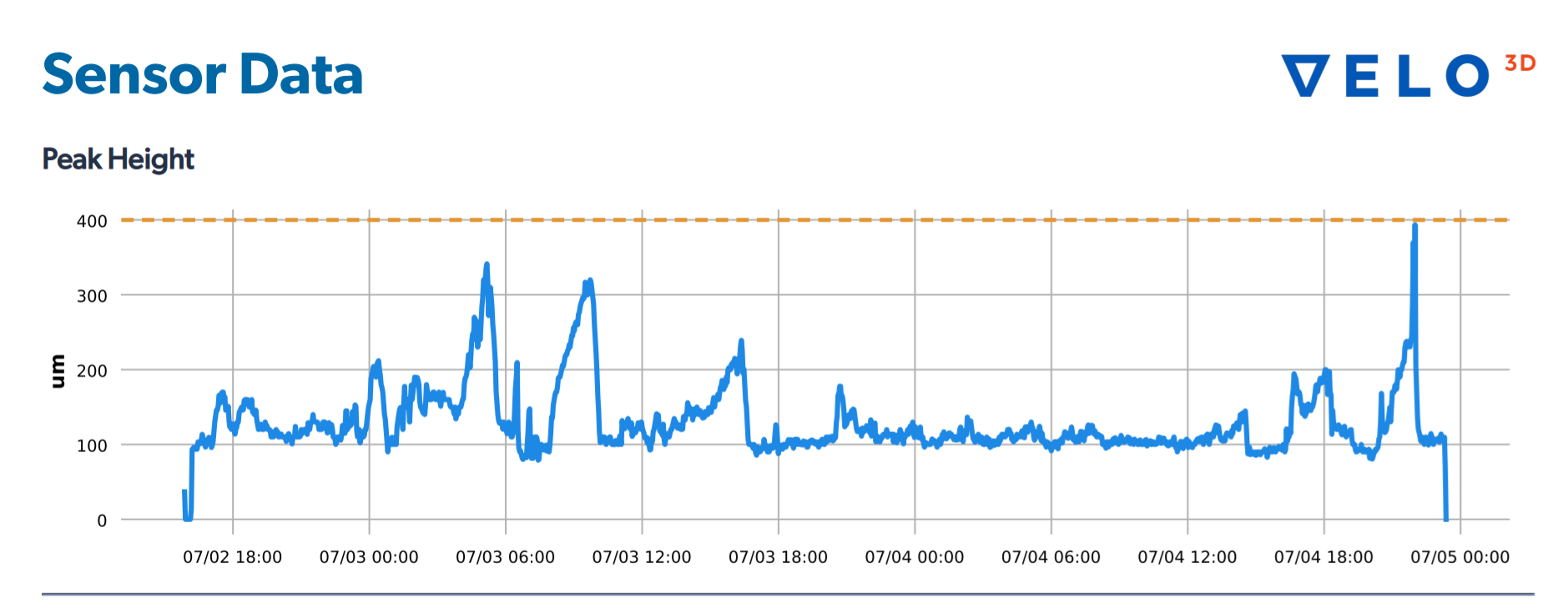

Next-generation AM systems can detect variations in layer height and identify any signs of unwanted protrusions; crossing the warning threshold will alert the user.