AM, Scanning, Laser Marking and Welding in One Machine

December 21, 2021Comments

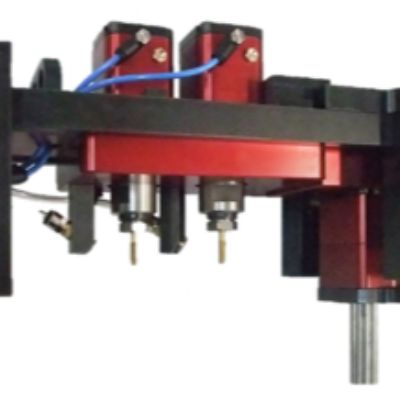

At Formnext…Nikon introduced the Lasermeister 102A, which employs a high-precision laser to perform metal processing—providing additive manufacturing (AM) capabilities while also enabling laser marking and welding. This model offers new capabilities in powder titanium modeling and processing, and also processes conventional stainless steels, high-speed steels and nickel-based alloys. Rollout of this machine follows introduction of the 100A by Nikon in 2019 and the 101A in 2020. Nikon plans to release the 102A for sale in Europe and North America in 2022.

At Formnext…Nikon introduced the Lasermeister 102A, which employs a high-precision laser to perform metal processing—providing additive manufacturing (AM) capabilities while also enabling laser marking and welding. This model offers new capabilities in powder titanium modeling and processing, and also processes conventional stainless steels, high-speed steels and nickel-based alloys. Rollout of this machine follows introduction of the 100A by Nikon in 2019 and the 101A in 2020. Nikon plans to release the 102A for sale in Europe and North America in 2022.

The Lasermeister 102A, with a 150-mm-dia. 150-mm-high build area, features a five-axis modeling system and 360-deg. scanning to provide enhanced 3D-alignment-measurement accuracy. The system observes the molten state of the melt pool to control and stabilize modeling, according to Nikon officials, which enables uniform profiles on edges for improved productivity. Compared to the 101A, modeling speed reportedly has approximately doubled in the 102A, with improved dimensional accuracy and surface roughness.

See also: Nikon Metrology, Inc.

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingWaterjet Optimizes Accuracy, Minimizes Taper

Thursday, July 3, 2025

In-Die Operations

In-Die OperationsUnits for In-Die Tapping and Insertion

Wednesday, July 2, 2025