Conveyor operation is controlled by a PLC integrated with the press controls, providing feedback to and from the presses in the event of production interruptions. The conveyor setup includes a broadcast unit that oversees delivery of scrap to two separate scrap bins located outside of the building. The broadcast unit employs a laser sensor to determine the level of scrap in the bin and indexes the unit, ensuring that excess scrap is not spilled and that both bins are safely and efficiently loaded. Laser sensors, standard on these scrap-handling systems, are less affected than ultrasonic depth gauges—often used by conveyor manufacturers to determine scrap levels—by environmental conditions, especially important when scrap bins are located outside of the plant.

Simple Design Eases Maintenance

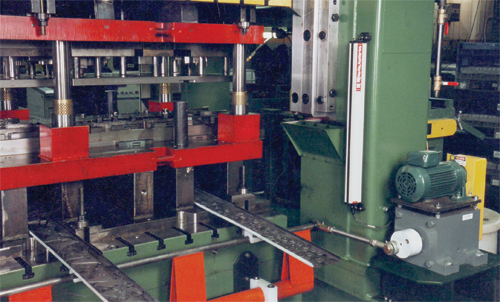

With the Shuffle Drive, an electric motor moves a drive shaft on an output hub through a reciprocating motion. As the drive shaft accelerates, material on the conveyor tray is pushed forward several inches, where it remains while the shaft slowly returns to its original position, and then the cycle begins again. Thus the material, whether lightweight or heavy, shuffles its to its destination quickly and quietly, according to Pressroom Techniques officials.

|

| After transport through a below-floor conveyor, scrap is dropped into bins outside of the plant. This chute automatically swivels to empty into a second bin should the first bin become full. |

They also note that the simple conveyor design eases maintenance and promotes reliability. The direct-drive motor and shuffle drives mean no belts or chains to break or maintain, and the design incorporates few wear-prone pinch points that characterize many conventional conveyor designs. The nonvibratory system eliminates risk of damage to the floor-anchor system or the drive itself. Adding to reliability, according to Pressroom Techniques officials: Many parts are rated in excess of the system’s actual performance. For example, the drive unit’s bearings are rated for 25,000 hr. at 500 rpm while the unit actually operates at only 70 rpm.

The under-floor Shuffle Drive has a slope of approximately 0.5 in./ft. over the length of the pit. Its design allows it to be installed in virtually any pit and be serviced in tight spaces, according to Mayfran officials. For example, drive units can be installed either above or below the trays depending on the needs of the application, and all of the system’s large fasteners have mechanical tensioning nuts. As a result, large wrenches, difficult to wield in tight spaces, are not required to tighten or loosen the nuts.

The Shuffle Drives have been maintenance-free since their install, according to Cannon officials.

“They eliminate scrap buildup at points found in traditional conveyor systems,” says Ronald J. Truant, former Cannon vice president and now a special consultant involved in equipment procurement, project management and expansion projects for the company. “The system is reliable, efficient and simple to clean and maintain.”

The scrap-handling system also helps Cannon save on stamping lubricant. The slight incline of the pit system enables gravity, aided by an air knife, to push lubricant through holes drilled along the length of the tray and into a collection trough below. Cannon collects the used lubricant and filters it for reuse.

Simple to Expand

Cannon has factored possible expansion of production into its plans, with provisions to add two presses, both of which would use the Shuffle Drive under-floor scrap removal system. The system, according to Mayfran officials, can be extended the necessary 30 ft. in a matter of hours. MF

Information for this article provided by Mayfran International, Cleveland, OH; tel. 440/461-4100; www.mayfran.com.

See also: Mayfran International, Inc.

Technologies: Pressroom Automation

Video

Video