AGVs and Cantilever Racking Boost Warehouse Efficiency

April 25, 2025Comments

When metal service center Central Steel & Wire (CS&W) decided recently to move from the Chicago facility that had been its home for 80 yr., it envisioned creating a state-of-the-art product depot and service center using the industry’s most efficient material-handling technology. With its new facility, encompassing 900,000 sq. ft. and opened in 2023 in University Park, IL, the firm ultimately left behind a labor-intensive method of material handling in favor of using automated guided vehicles (AGVs).

Says Nicole Giesie, vice president of operations at CSW—a member of the Ryerson family of companies: “The change allowed us to use driverless vehicles to store and pull materials to fulfill customer orders."

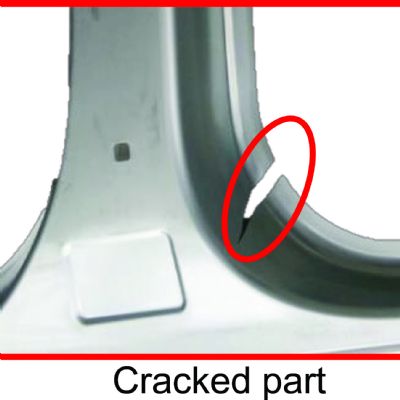

The greatest benefits from the use of AGVs, however, could only be realized by developing a new facility that incorporated racking with consistent pocket locations, evenly distributed and available throughout the location. The presence of damaged racking arms in the existing facility would have reduced the effectiveness of the AGVs, Giesie notes.

The payoff for the AGV investment: increased material-handling efficiency and accuracy, reduced labor, and decreased damage to racking, equipment and structures. “With AGVs, we now can utilize our workforce in other value-added tasks rather than just moving material throughout the facility,” Giesie says.

The facility includes 18,000 storage locations to accommodate 6000 product SKUs that have a combined weight of 50 million lb. of carbon and stainless steel, and aluminum and specialty alloys. Supplying storage racks for the facility: Steel King Industries, Stevens Point, WI. The facility employs Steel King’s I-beam cantilever racking for 1300 uprights and guardrail products. I-beam cantilever steel storage racks allow access from both sides, saving horizontal space normally lost to rack structure. They also minimize fork-truck damage and allow for faster load and unload times.