Enter Pressroom Automation

In dealing with the need to attract the next-gen workforce, metal forming and fabricating manufacturers find some relief by bringing in automation. Automation can address the repetitive, straining, dirty tasks that injure and bore humans, such as operating a single-hit gap-frame press. The dullest! Or post-op parts grinding. The dirtiest! By incorporating automation, fabricators address their high-turnover positions and make these roles more engaging.

Many opportunities are available to incorporate automation in the press shop:

- Auxiliary press equipment

- Transfer systems

- Controls, electrical updates

- Traditional automation

- Robots

- Predictive condition monitoring

- Design software

- Production control software

- Machine learning software.

Two additional automation opportunities fall under the collaborative automation category: Autonomous mobile robots (AMRs) and collaborative robots (cobots).

Collaborative Press Automation Puts the Worker at Center

With a number of technology choices out there today, choosing one can feel overwhelming. But with attracting and retaining a quality workforce the primary challenge, collaborative automation is a best-fit strategy to put people at the center of technology decisions. Collaborative automation pairs the technical capabilities and consistent repetitiveness of automation with the unique skills and flexibility of human specialists in the same workspace.

With a number of technology choices out there today, choosing one can feel overwhelming. But with attracting and retaining a quality workforce the primary challenge, collaborative automation is a best-fit strategy to put people at the center of technology decisions. Collaborative automation pairs the technical capabilities and consistent repetitiveness of automation with the unique skills and flexibility of human specialists in the same workspace.

Collaborative automation aligns closely with the European Commission’s Industry 5.0 concepts. While Industry 4.0 is defined by machine-to-machine communication for consistent quality, flow and data collection, Industry 5.0 represents a new age that brings the human touch back into production. It is about people and automation working side by side to create individualized products, services and experiences.

“This approach provides a vision of industry that aims beyond efficiency and productivity as the sole goals and reinforces the role and the contribution of industry to society,” the European Commission says.

“We are now in an age where industry must consider other factors as it evolves, including sustainable production, a human-centric approach to the workforce, and resilience using flexible and agile technologies,” the commission continues. “It places the well-being of the worker at the center of the production process and uses new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet.”

Collaborative automation offers clear benefits in each of these areas, enhancing productivity and supporting the well-being of the workforce. Collaborative automation contributes to company resilience through versatility. Workplaces can become human-centric, removing people from repetitive or dangerous work to allow them to focus on higher-level value-creation tasks.

Traditional Automation Compared to Collaborative Automation

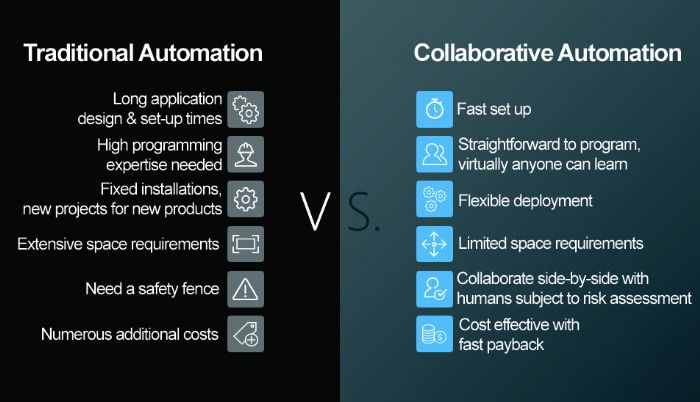

Here we outline some of the differences between “traditional” and collaborative automation.

Generally, traditional automation works well for high volumes to secure a positive return on investment. A high level of programming expertise may be needed; typically, traditional automation requires that a controls engineer or a robot technician perform the programming. Installations are affixed to a few products or part numbers, and equipment requires dedicated, separate space with a safety perimeter and fence to protect personnel.

Inversely, collaborative automation typically is more mobile and can be deployed flexibly for various products and configurations. It is designed for fast setup and ease of use so that nearly anyone can learn and implement the technology.

Many different collaborative automation technologies have been developed: lift-assist exoskeletons; movement-tracking wearables; virtual-reality training; augmented-reality operator-guidance systems; tele-operation maintenance robots; material-handling AMRs; and machine-tending cobots. These technologies dramatically improve productivity, drive quality and boost employee engagement through side-by-side, human-automation work on dull, dirty, dangerous tasks.

Automated Material Handling Can Improve Safety

Nearly 25,000 forklift-related injury incidents occurred in United States workplaces between 2021-2022, according to the National Safety Council. Moving material around facilities is an integral part of production—and the need to do it safely and efficiently is just as important. AMRs transport raw materials and components using sensors to navigate safely. AMRs may move on fixed “bus-route” paths between work cells or on flexible “pull-calls” to bring materials on-demand.

Automated inbound logistics with long hauls between dock and storage areas can replace forklifts. In the press shop specifically, AMRs transfer components to the production floor, and finished goods to shipping, and pick up and remove waste materials such as empty pallets or scrap bins.

Collaborative Robots Work Alongside Humans

Cobots are engineered purposefully to be human-sized automation. They work alongside operators (following a risk assessment). Cobots’ collaborative aspect doesn’t stop with the built-in safety functionality, however. Their simplified interfaces and intuitive touch-to-teach functionality allow manufacturers to deploy them quickly in the press shop to accomplish a host of tasks.

Using multiple end-of-arm tools, cobots tend single-feed gap-frame and other presses; and perform insertion pin-stamping, part handling, destacking, bin picking, assembly and packaging. Metal formers and fabricators often redeploy their cobots around their production floors to pivot production quickly as demand requires. Cobots integrate into existing production lines easily because they are compact and lightweight. Multiple programs can be stored and reloaded with the press of a button.

Taking a Human-Centric Automation Approach

In a recent Gartner Digital Markets survey, nearly half of manufacturers reported having buyer’s regret after a recent technology purchase. So how can they avoid this and experience a successful technology installation? Three key steps may improve metal fabricators’ outcomes and help stampers make better technology choices.

- People. First and foremost, they must put their frontline workers at the center. They should meet with them, talk to them, work with them, and find out what they think is hard or painful about their jobs. What do they dislike? Manufacturers should focus on what positions have the highest turnover and what production processes are considered dull, dark, dirty or dangerous.

- Process. Rather than referencing online manuals and work instructions, manufacturers should go talk to the people on the floor and understand what they do. Many steps in the process may be undocumented. Knowing the real process, rather than the documented one, may save manufacturers from making purchase decisions that they’ll regret.

- Product. Once manufacturers have listened actively to a diverse set of stakeholders and really learned the true processes to make parts, they can determine accurately what technologies will solve their problems.

The most successful companies always address challenges in this order: people, process, product. Making a strong technology decision this way enhances productivity, drives quality and boosts worker engagement. The key to attracting the next-gen workforce just may be the purposeful and strategic placement of collaborative pressroom automation. MF

View Glossary of Metalforming Terms

See also: Universal Robots

Technologies: Pressroom Automation

In a mid-2023 survey, the National Association of Manufacturers asked manufacturers to rate their top five challenges. Almost 75% of respondents said that attracting and retaining a quality workforce ranked number one. Traditional company goals of productivity and quality did not even rate among the top five challenges. This represents a major shift in company priorities and requires a major shift in corporate success strategies. Now, human resources must be at the center of corporate strategy.

In a mid-2023 survey, the National Association of Manufacturers asked manufacturers to rate their top five challenges. Almost 75% of respondents said that attracting and retaining a quality workforce ranked number one. Traditional company goals of productivity and quality did not even rate among the top five challenges. This represents a major shift in company priorities and requires a major shift in corporate success strategies. Now, human resources must be at the center of corporate strategy.  An effective and supported talent pipeline has a direct, positive effect on a plant’s productivity, ability to serve customers and profitability. Conversely, a mistake made in the press shop caused by an inexperienced temporary workforce hurts. As a commercial parts supplier in the South found out the hard way recently, an inexperienced press operator + the wrong material + the wrong shut height = buying a new press.

An effective and supported talent pipeline has a direct, positive effect on a plant’s productivity, ability to serve customers and profitability. Conversely, a mistake made in the press shop caused by an inexperienced temporary workforce hurts. As a commercial parts supplier in the South found out the hard way recently, an inexperienced press operator + the wrong material + the wrong shut height = buying a new press.

Video

Video