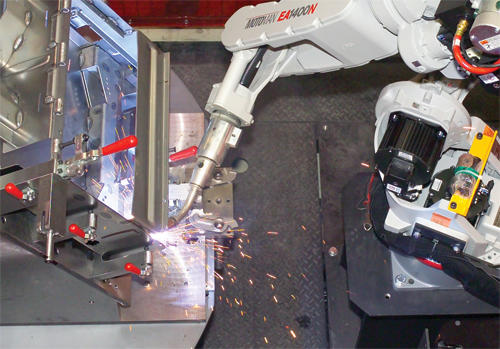

Justify Automation with High Part Volume

To justify an automation investment, companies need to ensure that their part volumes are high enough, as a robot’s key benefit is the ability to produce high volumes of quality welds. Realistically, however, even though many small fabricators may lack such high volumes for any one assembly, these facilities may be able to automate two or three smaller-volume applications and program a robot to weld those different parts instead.

Part volume is a critical factor in estimating return on investment—labor comprises as much as 75 percent of the cost of a semiautomatically welded component. Accordingly, even if a metalformer plans to produce the same number of parts, it may be able to justify the investment due to the amount of labor that an automated welding process can eliminate.

Evaluating the Facility

Facilities need know how much space they can devote to fixed automation and robotics, as the physical footprint of these cells and the amount of space required for the flow of raw materials exceed that of semiautomatic welding processes. Although welding automation can consume large portions of a plant’s real estate, small facilities still can make automation work by purchasing fewer pieces of automation equipment, programmed to perform multiple tasks. They can outfit robots with various toolsets that enable them to work on a number of different assemblies, while occupying a relatively small footprint.

Additional welding power sources and ventilation probably will be needed when integrating automated cells. The optimum power supply for a fabricator that employs automation is 480-V three-phase.

The facility also needs to consider bulk delivery of welding wire and shielding gas. Instead of purchasing 40-lb. spools of weld wire, for example, a metalformer might purchase 600- or 900-lb. drums. And, in terms of shielding-gas delivery, the priority is to optimize robot run time by investing in manifold systems that eliminate the downtime associated with frequent gas-cylinder changeout.

Many manufacturers, after they’ve decided to implement automation, opt to work with a third-party system integrator, knowledgeable about all aspects of facility modifications required for automation. Integrators also can help with important safety regulations that apply in the fabricator’s region, country or state, in addition to those specified by OSHA and the Robotic Industries Association.

Supervision of the Automated Cell

Automation doesn’t necessarily imply complete independence from human insight and supervision. Metalformers should assign a skilled welder, who knows the process, the tasks of programming the robot or fixed-automation system, and troubleshooting the process as needed. Otherwise, facilities should be prepared to vet robot OEMs to determine the availability and costs associated with OEM-based training of their personnel. Some automation companies may offer deals that include training for high-volume purchases, and companies can expect this training to last one to three weeks depending on the certification level desired.

Prior Planning Prevents Poor Performance

Automating welding processes can dramatically increase productivity while at the same time decrease labor costs and improve weld quality. Transitioning to automation, however, shouldn’t be done impulsively—automation is not suited to every facility or process. Failure to complete an upfront evaluation of the current semiautomatic welding process could result in an imperfect automation solution that requires constant babysitting. However, following a meticulous evaluation of the factors described above, facilities can transition to an automated process that requires only nominal supervision and generates a solid return on investment. MF

View Glossary of Metalforming Terms

See also: Miller Electric Mfg. Co.

Technologies: Pressroom Automation, Welding and Joining

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Enhanced Welding Helmet Features Digital Interface, Extended...

February 12, 2025