Remote Monitoring, Visualization and Optimization of Stäubli Robot Fleets

March 7, 2023Comments

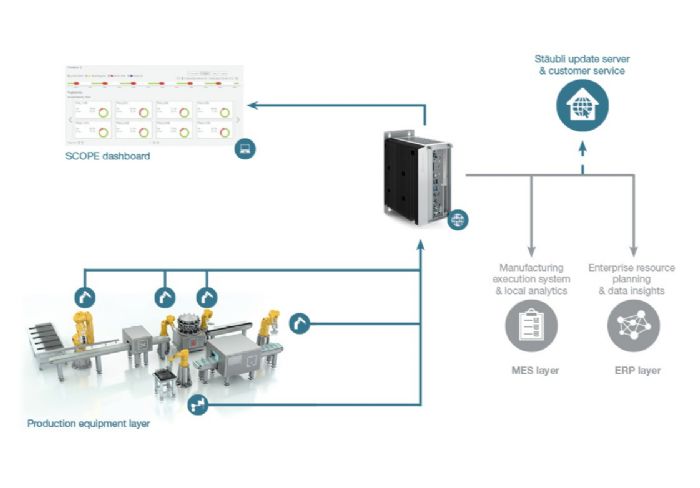

The new Scope platform from Stäubli reportedly provides remote monitoring, fault identification, visualization and optimization of Stäubli robot fleets. Scope—the acronym stands for “Smart, Connect, Optimize, Prevent and Enable”—summarizes the nature of this digital solution for robot fleet monitoring, according to company officials, with the onsite platform aggregating, processing, analyzing and visualizing robot-specific data. Users can view relevant operating data for each individual robot system on a central dashboard. This allows, say Stäubli officials, for detecting irregularities or gradual departures from spec, and for taking appropriate preventive action before quality is compromised, components become damaged or the production line grinds to a standstill.

The new Scope platform from Stäubli reportedly provides remote monitoring, fault identification, visualization and optimization of Stäubli robot fleets. Scope—the acronym stands for “Smart, Connect, Optimize, Prevent and Enable”—summarizes the nature of this digital solution for robot fleet monitoring, according to company officials, with the onsite platform aggregating, processing, analyzing and visualizing robot-specific data. Users can view relevant operating data for each individual robot system on a central dashboard. This allows, say Stäubli officials, for detecting irregularities or gradual departures from spec, and for taking appropriate preventive action before quality is compromised, components become damaged or the production line grinds to a standstill.

Real-time data collected by Scope also can be communicated to higher-architectures layers or databases and analysis tools. The platform can forward data via MQTT, HTTP response and websocket, making possible connection to a user’s enterprise resource planning, manufacturing execution and other systems.

Scope gives manufacturers an overview of the status of all robots, enabling them

to evaluate this data manually and respond instantly if necessary, or use

machine evaluations for predictive maintenance, with the option of running

their own AI-controlled optimization processes.

And, Scope reportedly allows future functionalities and updates to be loaded

and used in practice quickly and with minimal effort.

See also: Staubli Corporation

Technologies: Pressroom Automation