Mark Variable Data on Steel Coil

August 1, 2008Comments Matthews Marking Products, Pittsburgh, PA, has introduced an integrated system for high-quality inkjet marking of variable data on steel coil. The steel-coil marking system can be customized to accommodate special requirements.

Recently installed at one mill, the new system allows products to be marked with dynamic (variable) message information such as production date, operator information, plant location, date/time and part number. Print messages are changed via a PLC or computer in the control room.

With features such as a kickplate bracket to protect printheads when a weld passes underneath the heads, automatic ink priming at print startup and flushing (when not printing) functions, and uniquely formulated removable inks, the system is ideally suited for automated steel-production lines.

The system consists of the I-Mark R44e printhead controller, capable of controlling as many as 16 print heads; long-life, low-ink-consumption Jet-a-Mark 8000-series printheads; Mattcom software to interface with Allen Bradley or other human-machine interfaces for simple programming of print messages; and Matthews SCP240A removable ink.

Matthews Marking Products: 412/665-2504; www.matthewsmarking.com

See also: Matthews Marking Products

Technologies: Quality Control

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Quality Control

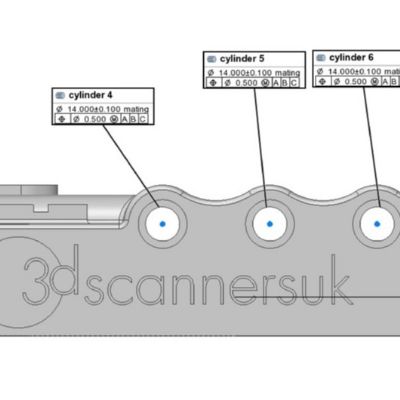

Quality ControlOnline GD&T Training

Tuesday, October 29, 2024

Use Lean Six Sigma for Efficiency & Quality Improvement

Daniel Schaeffler Friday, October 27, 2023

Management

ManagementSeeking Small Victories: Continuous Process Improvement

Daniel Schaeffler Monday, September 25, 2023

Quality Control

Quality ControlAn Introduction to Quality Management Systems

Daniel Schaeffler Thursday, July 27, 2023