|

| This multi-color printer represents one of many new investments at Mines designed to support AM education and research.

|

“We started ADAPT back in 2016 with a grant from the State of Colorado,” Brice says. “That grant, and establishment of ADAPT, focused on what we saw as a gap in the academic community involving understanding of the additive process, relationships between properties and the creation of correlations between how an AM machine is set up and the material properties that result. With input parameters numbering in the hundreds for many machines, how those parameters translate to final properties still isn’t quite known.

“You can buy a machine and the machine’s manufacturer can provide settings to run a part,” he continues, “but you really can’t predict the quality of the part coming out of that machine. By encompassing the materials, the design and the data aspects, we think that ADAPT fulfills that full spectrum of what engineers need to know when applying AM technology in the real world.”

Thus arose ADAPT, with the mindset of conducting high-throughput characterization, and also employing artificial intelligence to draw correlations.

“In our lab we set the knobs in many different ways,” Brice explains, “run samples through, analyze those samples in a high-throughput manner and then let algorithms make empirical correlations that connect settings to outcome properties.”

Early on, ADAPT employed characterization equipment, but with no 3D printers on hand, relied on partners to provide material from their printers. From the data, ADAPT has begun building models that offer predictive capability, reports Brice.

ADAPT’s 20-some member companies and organizations gain access to lab findings and collaborate on joint research, primarily in metals, to accelerate the material-qualification process. Ceramics also attract attention, says Brice―no surprise given that Golden is home to CoorsTek, considered the largest engineered ceramics company in the world. Mines’ strength in ceramic engineering also drives research on that front.

AM Education Reaches Across Disciplines

From ADAPT grew a new education program at Mines, with the realization that AM requires competence across a variety of disciplines.

“AM requires disciplines that don't reside within traditional educational tracks such as mechanical, materials or electrical engineering, but draws from many of those,” says Brice, commenting on challenges in developing an ideal AM curriculum that accommodates AM while extending beyond to other leading-edge methods of building things. Hence the initiative’s name: the Advanced Manufacturing Program (AMP).

|

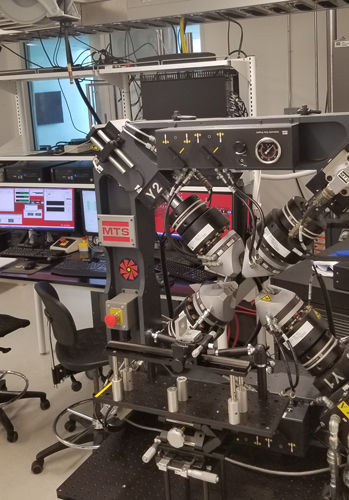

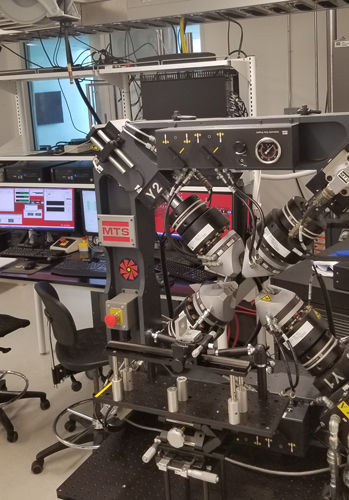

| Open-architecture AM machines at Mines, such as this metal printing equipment, enable students and researchers to adapt equipment for various research needs, including the addition of lasers, cameras and more.

|

The program recognizes the evolution of manufacturing, including AM along with agile business practices such as just-in-time manufacturing and mass customization. These disruptive concepts, as the program’s website describes, become difficult to implement with legacy manufacturing techniques. Recognizing the need for companies to adapt to these new practices to remain competitive and expand their markets, Mines created the program as a means to provide interdisciplinary training. The goal: serve the next generation of manufacturing engineers that must work with these disruptive technologies. The program includes the aforementioned 10-course non-thesis Master of Science and four-course Certificate programs, with both expected to be fully online for the 2020-21 academic year.

The online 30-credit-hour master’s program consists of four core courses for the AM track—students select at least three program-approved elective courses with an option to replace six credit hours with project-based work via internship. The current 12-credit-hour online certificate program, focusing on AM, includes fourcore courses, with students choosing at least three with the option of taking an elective course. A new certificate program now under development by Jenifer Blacklock, AMP associate director, and expected to go online for the 2020-21 academic year, focuses on smart manufacturing. This program is based on learned optimization skill sets such as lean, lifecycle assessment, linear optimization modeling and implementation plans.

|

How ADAPT Helps ‘Optimize for Additive’

The Alliance for the Development of Additive Processing Technologies (ADAPT) at the Colorado School of Mines, an industry-academia consortium, leverages the latest developments in materials characterization and machine learning to enable members to, as ADAPT’s tagline reads, Optimize for Additive.

ADAPT explores complex process-structure-property relationships unique to AM methods, with a goal of increasing fundamental understanding about how the process variables impact the material microstructure and final part properties.

Also, ADAPT employs high-throughput characterization and materials informatics to model the complex melting thermal histories that occur in AM processes. And, to optimize parts for AM, ADAPT uses data informatics to integrate part quality, microstructure and topology in the design process.

Members include Colorado School of Mines, Ball Aerospace, Lockheed Martin, Boeing, Moog, 3D Systems, Elementum 3D, GE Additive, Sciaky, EOS of North America and others. See the full member list, and learn more about ADAPT and its research projects at www.adapt.mines.edu.

|

“The master’s non-thesis track is very targeted,” Brice explains. “While most of our students arrive straight from their bachelor's degrees, we’re hoping to target the working community―recent hires and those looking to expand their understanding of advanced-manufacturing techniques. Additive doesn't solve every problem, but is another tool in the toolbox. Every engineer should know AM’s capabilities and limitations, and that is what we’re trying to offer.”

The certificate program also targets working professionals, according to Blacklock, who expanded on course offerings provided through AMP.

“Everything will be online to best serve working professionals,” she says, “and I’ll be creating online courses focusing on optimization, lean manufacturing, lifecycle assessment, engineering statistics and more.”

The course development again speaks to the role of AM not as an isolated process, but part of the entire advanced-manufacturing landscape.

Brice and Blacklock expect to deliver most courses by the fall of 2020, with some debuting sooner as they become accredited. As the online course menu expands, Brice and Blacklock expect enough courses to comprise the online master’s degree within two years.

Beyond the online courses, Brice expects to encourage students to come on campus for intensive hands-on work in the Advanced Manufacturing Teaching Lab. The lab gives students the opportunity to work with metals, ceramics and biological materials while optimizing structural design, and capturing and interpreting process data.

“Lecturing is fine, but the lab forces students to think like they would in a job: How am I going to make this part on this machine? That's really where they’ll learn the most.”

Wealth of AM Machines, Test Equipment on Hand

Via a tour with Brice, 3D Metal Printing learned more about Mines’ lab component, used both for instruction and for ADAPT projects. First stop, the “Death Lab,” as Brice calls it, where test equipment rides parts and samples to failure. On one test stand sat a door bracket for an armored vehicle.

ADAPT had partnered with the U.S. Army, Air Force Research Lab and Elementum 3D in a one-year program to redesign armored-vehicle door hinges that often failed in the field and took months to replace. Using data sets to predict quality, the team designed new hinges―considerably stronger and lighter than the legacy parts. Printed as a single piece was a direct, bolt-in replacement of what had been a six-part assembly.

The team “undertook a multi-step redesign and optimization to remove part weight,” Brice explains. “We integrated the hinge pin in a single build, then tested to failure to validate the new design. Interestingly, we used data sets from other materials and processes to predict the optimal configuration, as well as the machine settings to achieve optimal material properties.”

|

| The ‘Death Lab’ at Mines features equipment used to induce failure in parts, leading to more robust models that better characterize AM materials and processes.

|

Back on the tour, Brice showed off various AM machines, including an old powder bed fusion unit refreshed with a new laser and sensor capability developed by some members of Mines’ Physics department.

The lab currently is looking for equipment that enables synchronization of visual and thermal data during an AM build in order to better measure material and other build properties. Comparing such data from various builds can result in machine-learning correlations, according to Brice, that “in the end, provides predictive capability. We can predict different machine settings for different parts.”

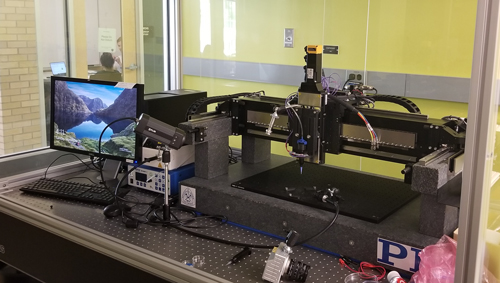

A walk across the street on the Mines campus took us to another AM lab that includes Markforged, Stratasys, HP and other nonmetal (ceramic, nylon, polymer, etc.) machines, including units built by students for project credits. One student-built machine includes a high-speed camera that provides thousands of images per second, enabling users to view the AM process in great detail. Another, a laser powder machine, may be fitted with a blue-wave laser, which provides improved coupling on highly reflective materials such as copper, according to Brice.

“While it's great to have the professional AM systems,” he says, “these student-built open platforms enable us to tinker, which is very valuable for the students and allows us to introduce unique capabilities into the equipment.” 3DMP

See also: Colorado School Of Mines

Technologies:

Video

Video