Risk Assessment

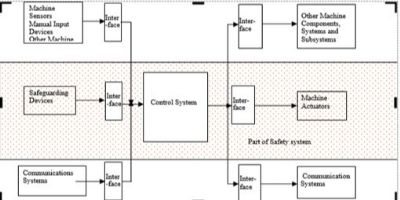

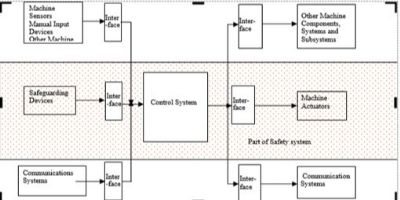

The B11.20 subcommittee recommends that users evaluate

whether existing IMSs have acceptable risk using generally recognized risk-assessment

methods. A risk-assessment document outlines the steps needed to bring a piece

of equipment into compliance, per the appropriate ANSI and OSHA codes. The assessment considers all aspects of the

safety system, as depicted in the accompanying diagram.

Recognize that zero risk does not exist and cannot be

obtained. However, a good-faith approach

to risk assessment and risk reduction should achieve an acceptable risk level.

Recognize that zero risk does not exist and cannot be

obtained. However, a good-faith approach

to risk assessment and risk reduction should achieve an acceptable risk level.

The risk assessment is a three-phase process, the first phase being the creation of the risk-adjustment (RA) document. The second phase is verification—review of the safety design’s ability to meet the intent of the RA. The third phase is actual validation testing of the final safety-control system (SCS) to ensure that it correctly performs the required safety functions as called out as risk-reduction measures in the RA document.

In addition, alternative methods of hazardous-energy control

should be analyzed and their risk-assessment documentation reviewed as part of

the overall safety-system review.

Shared Space

The press slide/die area presents

numerous opportunities for personnel to interact with equipment, and those

tasks cannot always be completed by following OSHA 1910.147/ANSI Z244.1

hazardous-energy-control lockout methods.

Therefore, these tasks must utilize alternative methods of hazardous-energy

control to comply with the standards. Here,

multiple pieces of equipment, under different control systems, exist in the

same space where tasks are being completed, thus the shared-space concept. This shared space is where ANSI B11.20 and

B11 standards provide requirements and guidance on how the various SCSs and

safety-related devices must be integrated to provide the proper safety-circuit

performance to meet requirements of a documented task-based risk assessment.

For example, consider an automated transfer press with a coil-feeding system providing material into the first die station. While seemingly most of the focus is on the hazards and safety control for the actual press motion, the tasks in the shared space also expose personnel to hazardous situations regarding the motion during the coil-feed process and with the transfer automation. Often, metal formers do not follow the requirements for the use of the alternative methods when interlocking the safety devices for this shared space with all three systems, as compared to just the press. It has been documented in the past two decades that for OSHA to consider the use of control circuits for alternative methods to lockout, they must provide effective protection. Effective in this context is defined “as effective as lockout” in a reliable fashion. This means that the safety-related interlocks for the control systems must be reliable in terms of their ability to fail in such a fashion as to remain in a safe state. Controls that do not meet these requirements require additional methods of isolation to the control circuit for the use of alternative methods.

In this example, unfortunately the press-transfer and coil-feeding automation often only are interlocked so that that their controls have their automatic function disabled, however the hazardous-motion control elements remain fully enabled, albeit in a manual-control fashion. This would not meet the analysis required—in a documented risk assessment—for appropriate risk-reduction methods for those tasks, nor the requirements of a control circuit providing for alternative-method hazardous-energy control. The addition of some simple safety circuits easily can be provided, but without completing a review and planning process during the risk-assessment phase of a project, it becomes more costly as an afterthought and can cause other hidden or future costs.

Other examples of the shared-space concept include tandem-press

lines with various types of press-to-press automaton, including robots;

blanking-press lines with coil-feeding and stacking automation; progressive-die

coil-fed press operations; and automated presses with blank-destacking/feeding

equipment. To utilize the concept of

alternative methods in lieu of lockout, ANSI standards such as B11.20 must be

followed, as well as the requirements for the use of alternative methods as

defined in ANSI Z244.1.

Layout Analysis Required

A layout analysis must be part of the review process for all

of these various IMSs found in the pressroom, to be part of the risk-assessment

and risk-reduction process. The analysis

will help clarify the span of control of the various safety devices used within

the IMS and help determine the required level of safety performance. ANSI B1.20, ANSI Z244.1 and additional B11 standards

such as B11.0, B11.19 and B11.26 all provide guidance, as well as the C-level

standards for the equipment such as B11.1, B11.2, B11.3 and B11.18.

To finalize the review and analysis for the control of hazardous energy and use of alternative methods in shared spaces found in IMS applications, refer to ANSI/ASSE Z244.1-2016 R2020, “The Control of Hazardous Energy – Lockout, Tagout and Alternative Methods.” This standard provides the following guidance to justify the use of alternative methods, with requirements detailed in various clauses of the document:

- A

practicability/justification analysis

- A

risk assessment

- Other

applicable evaluations as detailed in clauses in the standard.

This detailed documentation, along with the documentation created by following the guidance of ANSI B11.20, provides end users with defendable positions for the use of alternative methods for performing tasks in their stamping-related IMS applications. MF

See also: White Horse Safety, Inc.

Technologies: Safety

Recognize that zero risk does not exist and cannot be

obtained. However, a good-faith approach

to risk assessment and risk reduction should achieve an acceptable risk level.

Recognize that zero risk does not exist and cannot be

obtained. However, a good-faith approach

to risk assessment and risk reduction should achieve an acceptable risk level.