Plant-Wide Features Introduced in Machine-Monitoring Product

February 28, 2025Comments

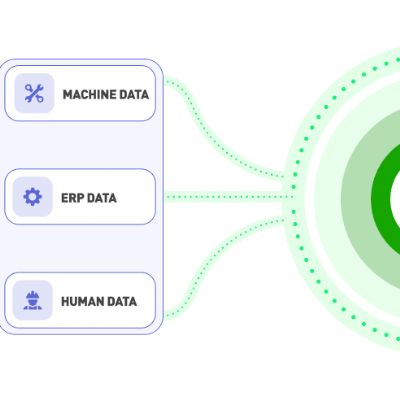

Guidewheel has introduced two new features for its FactoryOps

artificial-intelligence-powered machine- and operations-monitoring technology,

the Plant Pulse map and organization of machines by plant. Guidewheel works via

noninvasive sensors clipped over the

power supply of a machine, with data sent securely to the cloud in real time,

analyzed and translated to key metrics and visuals accessible on any device.

Guidewheel has introduced two new features for its FactoryOps

artificial-intelligence-powered machine- and operations-monitoring technology,

the Plant Pulse map and organization of machines by plant. Guidewheel works via

noninvasive sensors clipped over the

power supply of a machine, with data sent securely to the cloud in real time,

analyzed and translated to key metrics and visuals accessible on any device.

The Plant Pulse map, accessed from Guidewheel’s Scoreboard page, enables views at a glance of plant runtime performance. The dynamic view provides a live pulse of all locations and allows users to drill down to the plant or machine level quickly to explore any issues. Plant Pulse enables operational leaders to compare performance across locations, ensure that each plant is performing at its full potential and help solve problems before they escalate, according to company officials.

As many Guidewheel users already group machines by type, location and more using device lists, another new FactoryOps feature allows for organizing those machines into plants. This eases the ability to group machines by physical location and apply relevant shift schedules, users and tags to each plant. Advantages include automatic tracking of current-shift performance in Guidewheel’s Scoreboard, streamlining of multi-plant reporting and improved use of the Live Map feature to access live views of entire operations.

Overall, Guidewheel reportedly allows users to make data-driven decisions to improve team efficiency with real-time alerts and by identifying top issues/trends with each machine, shift, reason code, etc.

See also: Guidewheel

Technologies: Sensing/Electronics/IOT

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Work-Instruction Software Enables Workers to Activate, Monit...

August 5, 2024