AMUG Presentation: Software Simulation Yields Successful Missile-Part Build

March 22, 2019Comments

|

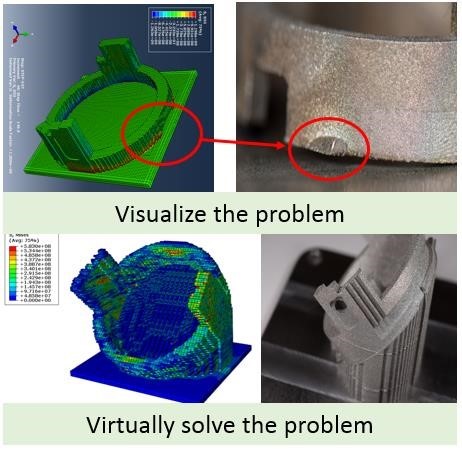

| Employing a suite of AM design and simulation software enabled Raytheon to identify and solve residual-stress and other issues prior to printing a missile part, saving time and reducing material scrap rates. |

The project will be detailed in a presentation at AMUG 2019 in Chicago, IL, on Monday, April 1 at 4:30 p.m. 3D Metal Printing has described aspects of the project as well.

“With the promise that laser powder bed fusion has in AM, there also are major pitfalls, such as defects, unmet net shape, high warpage, residual stress and surface roughness, void formations, and inconsistent density just to name a few,” explains Cody Godines, structures group leader at AlphaStar and project co-leader along with senior mechanical engineers Isis Roche-Rios and Alicia Leslie of Raytheon. “We were able to simulate all of these with the Genoa 3DP tool within the Ansys framework before printing.”

Another key component of a successful build: prediction of thermal history, material state and process maps.

“We found that knowing all of this information beforehand,” explains Leslie, “sets up for a successful final simulation with multi-objective optimization of the component and support structure to minimize mass and scrap rate while minimizing the pitfalls of AM.”

See also: Alpha Star Corporation

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

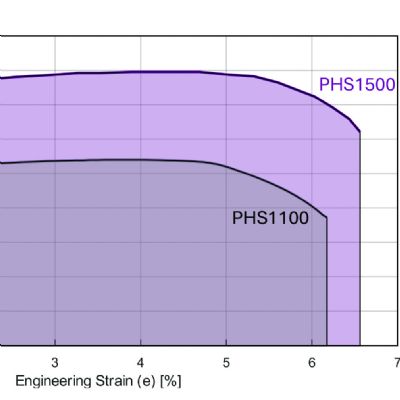

MaterialsLocal and Global Formability—Part 2: Effects on Material Sel...

Eren Billur April 29, 2024