"We

contacted experts in the field, and they told us, 'You can't do it. It's

physically impossible,'" Oppio recalls. "But we went back to the OEM

and said, 'Okay, it's going to be a struggle, but we're willing to take a risk

and experiment.'"

Despite the skepticism, Classic Tool & Die forged ahead, confident in its ability to innovate and find a solution. The team knew that success not only would solidify its relationship with the OEM but also establish the company as a leader in tackling challenging projects.

Solution: Innovative Die Design

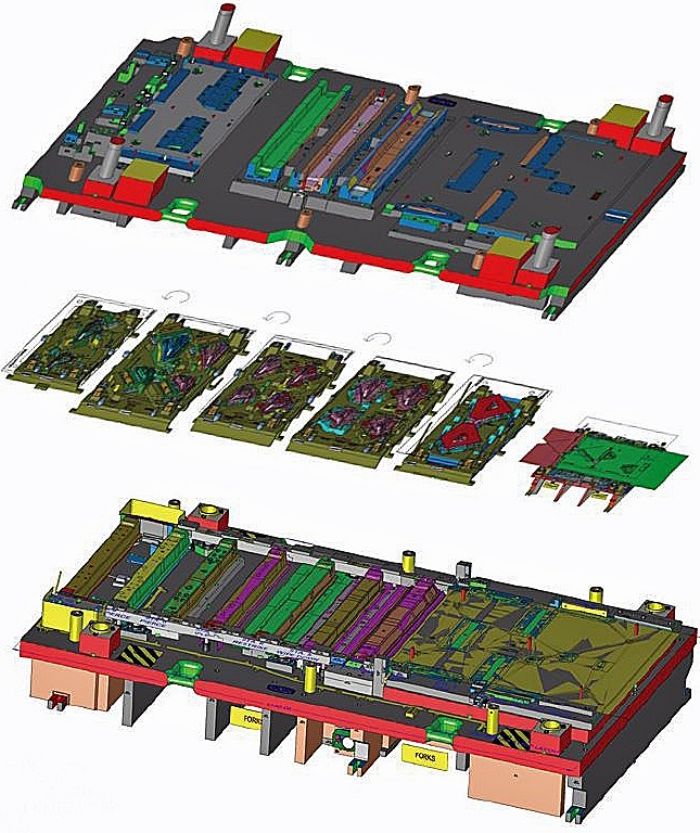

To

help it tackle this groundbreaking project, the firm turned to CAD/CAM software

from Cimatron, leveraging its surfacing, scanning and reverse-engineering

capabilities. Oppio explains that his team used the software to design an

innovative, hydraulically controlled binder system capable of automatically

adjusting pressure throughout the stroke. The team worked through three major

tool and hydraulic-system design iterations before achieving success.

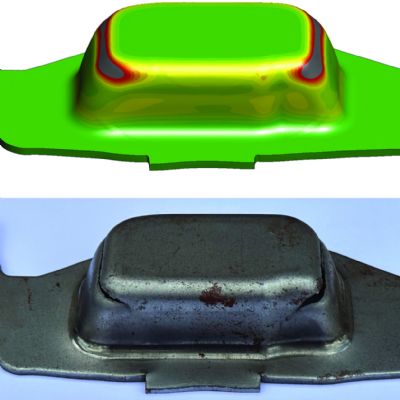

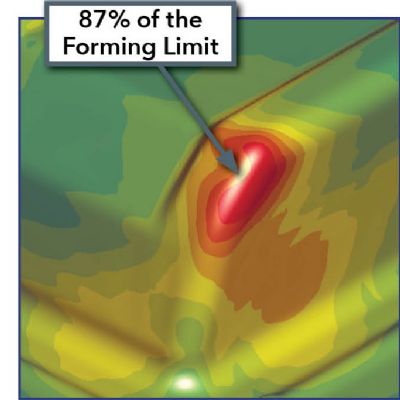

The

company collaborated with the University of Windsor on the project, tapping

into the expertise of researchers and engineers to help refine the design and

overcome the technical challenges. Meanwhile, the OEM handled formability

simulations, providing valuable insights into the workpiece-material's behavior

and the die's performance.

In

addition to the hydraulic challenges, the part presented complexities due to

its massive size and varying draw rates across the different areas. Classic

Tool & Die had to ensure that the draw pad maintained consistent motion

throughout the process, a critical factor in achieving the desired part quality

and preventing defects.

"Cimatron's

surfacing, in conjunction with reverse engineering and scanning, really helped

us with this project," Oppio notes. "The software's capabilities

allowed us to iterate on our designs and quickly find the optimal

solution."

Viewer

Stations on the Shop Floor

To

further streamline its processes and improve efficiency, and shift toward

greener solutions, Classic Tool & Die virtualized Cimatron and deployed

viewer stations on the shop floor. This allowed die makers to access 3D models

and drawings on large screens right next to the die, eliminating the need for

physical drawings and reducing the risk of errors.

"By virtualizing Cimatron and setting up viewer stations, we've seen a 75% productivity increase in floor assembly,” explains Oppio. “We’ve also reduced our carbon footprint compared to our previous process of plotting drawings and bringing them to the shop floor."

Also crucial to the project’s success: Cimatron's seamless integration with Classic Tool & Die's CNC machines. Operators were able to directly access part details and the entire die design on the machine control, eliminating data-translation issues and ensuring that they always had the most up-to-date information for machining.

"We've

built die-design libraries in the software for different customers and

requirements, including metric and imperial standards, as well as progressive-

and transfer-die configurations," Oppio adds. "This helps streamline

our processes and efficiently deliver high-quality tools and dies."

Results: Opening Doors to Innovation and Collaboration

Classic Tool & Die's willingness to take on this "impossible" project—and its successful execution—has opened the doors to a long-term, innovation-driven partnership with its automotive-OEM customer. The cutting-edge hydraulic binder system, which allows for varying pressures during the draw process, led to two patents and paved the way for annual experimental projects and further patent development.

"It

completely opened the doors for this OEM moving forward," Oppio says.

"We now take on an innovation project the customer every year, and patents

have been developed because of the projects we've created."

The

success of this initial project demonstrates Classic Tool & Die's ability

to push the limits of die design and hydraulics, solidifying its reputation as a

go-to partner for challenging, innovative projects. The company's relationship

with the OEM has since grown to include six major projects, each building upon

the foundation laid by that first experimental tool.

Looking

to the future, Classic Tool & Die continues to innovate and expand its

capabilities. The company recently installed a large 1500-ton Danly press (96 by

212-in. bed) equipped with a full robotic transfer system. This addition allows

it to offer specialized services for low-volume production runs and emergency

jobs.

"With

our new press and transfer system, we can take on even more challenging

projects and provide a wider range of services to our customers," Oppio

explains. MF

Information

provided by Cimatron: 877/596-9700, www.cimatron.com.

See also: Cimatron Technologies Inc.

Technologies: Software

When an automotive OEM approached Classic Tool & Die with an experimental project involving explosive forming of a firewall, Oppio and his team knew they faced a formidable challenge. The automaker needed to form a steel panel using a single-draw die while maintaining consistent binder pressure throughout the stroke—a feat previously deemed impossible by pneumatics’ experts, due to the inherent characteristics of gas compression, which increase as the die closes. Additionally, binder pressure had to remain constant regardless of press speed, adding further complexity to an already daunting task.

When an automotive OEM approached Classic Tool & Die with an experimental project involving explosive forming of a firewall, Oppio and his team knew they faced a formidable challenge. The automaker needed to form a steel panel using a single-draw die while maintaining consistent binder pressure throughout the stroke—a feat previously deemed impossible by pneumatics’ experts, due to the inherent characteristics of gas compression, which increase as the die closes. Additionally, binder pressure had to remain constant regardless of press speed, adding further complexity to an already daunting task.