Machine-Learning Software Enables Ford to Select Most Productive Stamping Processes

September 28, 2020Comments

Identifying the optimum stamping process for a given part design can be labor-intensive and time-consuming, relying heavily on a stamping engineer’s knowledge and skill level. By leveraging Knowledge Studio machine-learning software from Altair, Ford has been able to speed its stamping-process selection and increase first-time-through (FTT) rates.

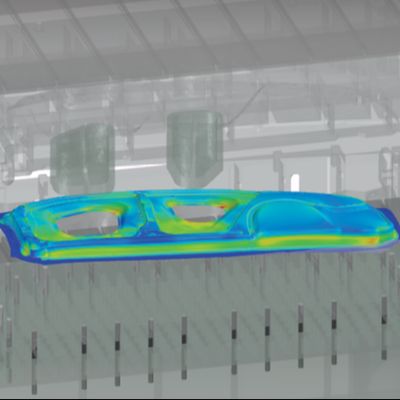

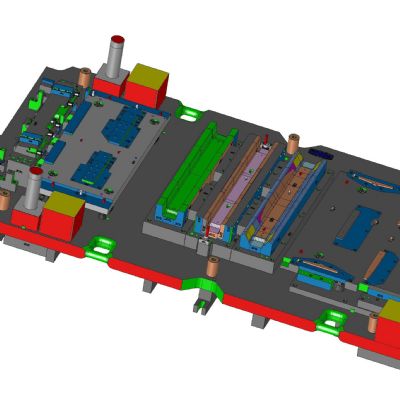

At Ford Mexico, as with many production facilities, multiple sheet metal stamping processes are available to form nested and individual parts, including progressive, transfer and tandem press lines. For a given part design, many factors determine the best or most efficient stamping process, including material type and thickness, part width, and desired surface finish. While process selection typically falls to the manufacturing-process engineer, growing design complexity, nonconventional material types and numerous process combinations prove challenging, often ultimately requiring a labor- and material-intensive trial-and-error prove-out process.

Material utilization represents a particularly critical benchmark. Most automotive plants expect 60-precent material utilization in stamping operations, with the remaining 40 percent considered wasted. Ford sought to improve these numbers, while simultaneously improving the selection of the right stamping process the first time and increasing its FTT rates.

To move toward achieving these goals, Ford Mexico began documenting and amassing its vast quantities of clean data associated with successful inhouse production runs. Spanning a 5-yr. period, process engineers recorded successful stamping processes for thousands of parts. The historical data provided valuable insight, but the question remained: How could Ford use this information to help automate and guide the selection of the best stamping process for a given part design?

More than 30 years ago, Ford began working with Altair to support the company’s product-development activities. Today, Ford employs Altair software globally to support the development of Ford cars, trucks and heavy equipment. That relationship would continue through this project.