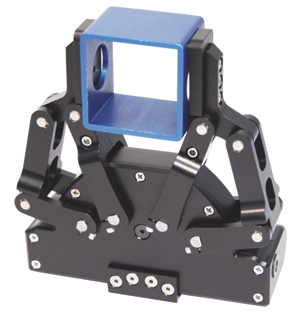

Two-Finger Adaptive Gripper Overcomes High-Mix Automation Challenges

July 1, 2012Comments

Robotiq, St-Nicolasis, Montreal, Canada, has introduced an innovative two-finger gripper to replace the use of robotic tool changers that provide only limited and expensive solutions when required to handle a variety of parts. Applications include high-mix processes such as light assembly, sorting and kitting, packaging, machine tending, bin picking and parts transfer. Says one recent customer of the gripper:

Robotiq, St-Nicolasis, Montreal, Canada, has introduced an innovative two-finger gripper to replace the use of robotic tool changers that provide only limited and expensive solutions when required to handle a variety of parts. Applications include high-mix processes such as light assembly, sorting and kitting, packaging, machine tending, bin picking and parts transfer. Says one recent customer of the gripper:

“A recent job for our robotic nut-welding cell (resistance welding) required us to load more than 30 different parts,” says Steve Spanjers, director of engineering at automotive stamper Marwood Metal, Tillsonburg, Ontario. “Having to design several custom grippers was a big concern. We found the two-finger adaptive gripper to be a flexible solution able to grip all of our parts, which reduced tooling costs and eliminated time consuming changeovers.”

Fully programmable, the robotic gripper provides:

Fully programmable, the robotic gripper provides:

• Three gripping modes–parallel, encompassing and inside grip–for handling different part geometries including flat, square, cylindrical and irregular.

• High payload-to-weight ratio coupled with long stroke, to enable handling of a variety of sizes in a compact form factor.

• Precise speed and force controls, for handling parts of different rigidities—from brittle to deformable to stiff.

• Accurate finger control, to minimize cycle times through partial open/closing.

Robotiq: 888/762-6847; www.robotiq.com

See also: Robotiq

Technologies: Tooling

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. CNC Punching

CNC PunchingHow Can We Resolve Our Slug-Pulling Problem?

Thomas Vacca Friday, April 25, 2025

Tooling

ToolingSimplifying the Complex

Tuesday, April 22, 2025