AMGTA Study to Compare Lifecycle Assessments of Aerospace Component

October 6, 2021

|

|

|

| AMGTA Study to Compare Lifecycle Assessments of Aerospace Component |

| The Additive Manufacturer Green Trade Association (AMGTA) announced that it has selected the Golisano Institute for Sustainability at Rochester Institute of Technology to conduct a lifecycle assessment comparing an additively designed and manufactured aerospace component to a traditionally manufactured component. “This new study will include as many as 18 different environmental indicators to quantify the environmental impacts that an optimized jet-engine LPT bracket has throughout its entire lifecycle—from material extraction to manufacturing, transportation, use, and its eventual end of life,” says Sherry Handel, AMGTA executive director. |

|

|

|

|

|

|

| nTopology October Free Webinar to Explore Topology Optimization in Aerospace Design |

| Topology

optimization is an effective generative design tool for weight

reduction, but aerospace components often operate under rapid dynamic

loads or high-frequency vibrations. nTopology addresses this issue in a

free webinar, Advanced Topology Optimization for Aerospace: Dynamic

Analysis, Manufacturability & Cost, October 12 at 11 a.m. ET.

Engineers from Cognitive Design Systems and nTopology will demonstrate

how to combine topology optimization with bionic design, lattice

structures and dynamic design analysis to address engineering,

manufacturing and cost requirements. |

|

|

|

|

|

|

|

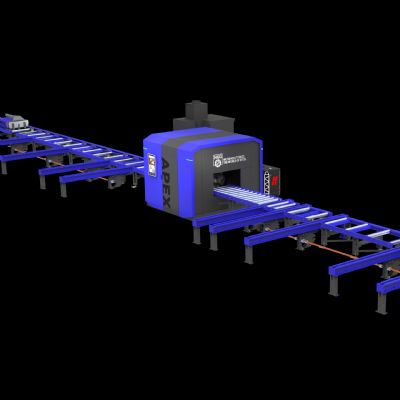

| Quintus HIP Headed to New Oregon AM Research Center |

| A Quintus Technologies hot isostatic press (HIP) will help anchor the new 30,000-sq.-ft. additive research facility at the Oregon Manufacturing Innovation Center Research & Development (OMIC R&D) in Scappoose, OR, when it opens next year. The Quintus QIH 48 M URC press will allow new research into 3D printing technology and optimized material properties. The press is equipped with Quintus’ Uniform Rapid Cooling, which combines HIP and heat treatment in a single process. Accelerated cooling under pressure minimizes thermal distortion and improves material properties. |

|

|

|

|

|

|

|

|

|

| In This Issue |

| Can 3D Printing Solve the Global Semiconductor Shortage? |

Let’s explore three semiconductor AM options that have demonstrated advantages: wafer-table thermal management; manifold fluid-flow optimization; and structural optimization and advanced flexures.

Predicting AM-Part Performance

Post-processing steps such as heat treatment, hot isostatic pressing

(HIP) and surface finishing, significantly affect AM-part performance.

Here we describe a probabilistic model developed by EWI to predict part

performance based on both the build process and the post-processing

technique. |

|

|

|

|

|

|

|

|

| Coming in 3DMP's Fall 2021 Issue |

- RAPID + TCT Wrapup

- Case Studies: Metal 3D Printers in Action

- FDA vs. ISO 13485: What Metal-AM Providers Need to Know

- Metal AM of Turbochargers

- Metal Stamper 3D Prints Die Sections and Transfer Tooling

- Digital Data Thread Brings AI to AM

|

|

|

|

|

|

Copyright 2021 3D Metal Printing, All Rights Reserved.

6363 Oak Tree Blvd, Independence, OH 44131

You have received this message because you have requested and are receiving

3D Metal Printing magazine, a product of the Precision Metalforming Association (PMA) or

we have had a prior business relationship with you.

To unsubscribe from future 3D Metal Printing e-mails.

To opt-out from all e-mails click here.

Technologies:

Other Processes

Other Processes Cutting

Cutting

Event

Event