MetalForming LIVE On the Shop Floor 2023: Pressroom Automation

April 25, 2023Comments

MetalForming LIVE On the Shop Floor includes interviews with metal forming executives discussing their company’s use of automation technology as well as videos from their shops featuring automation technology in action.

Case Study #1: Clips & Clamps Industries

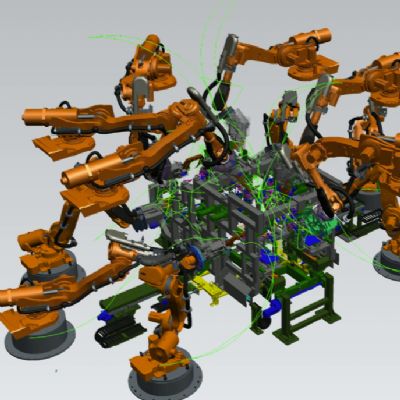

An automated lean cell at Clips & Clamps performs a series of value-added processes, including wire forming, cold heading, coining, piercing, stamping, resistance-spot welding and machine-vision inspection.

Case Study #2: Sukup Manufacturing Co.

A robot at Sukup Manufacturing destacks blanks and tends to two stamping presses to produce flooring supports for use in grain-storage operations. The robot loads 20-gauge steel blanks into a 300-ton mechanical press for forming, unloads the formed part (now a tube section) and transfers it to a hydraulic press for bending.

Speakers

- Jeff Aznavorian, President, Clips & Clamps Industries

- Tom Christofilis, President/Founder, IP Automation Inc.

- Will Healy III, Global Industry Segment Leader, Welding, Universal Robots USA Inc.

- Matt Koch, Chief Marketing Officer, Sukup Manufacturing Co.

- Craig Rice, Director of Manufacturing, Clips & Clamps Industries

- Tom Stocker, Director of North American Sales, Yaskawa Motoman

Sponsors

- Greenerd Press & Machine Co.

- OnRobot US, Inc.

- Wintriss Controls Group LLC

- Precision Metalforming Association

View Glossary of Metalforming Terms

See also: Precision Metalforming Association

Technologies: Bending, Pressroom Automation, Quality Control