MetalForming LIVE On the Shop Floor 2025: Automation Case Studies

April 30, 2025Comments

MetalForming LIVE On the Shop Floor includes interviews with metal forming executives discussing their company’s use of automation technology as well as videos from their shops featuring automation technology in action.

The spring 2025 On the Shop Floor took place on April 29 and featured Pennant, Inc. and Argon Industries.

Case Study #1: Pennant, Inc.

Specialty metal former Pennant, Inc. provides integrated solutions for stamped, fabricated, roll formed, welded and decorated assembled components serving the appliance, ConAg, EPC, heavy truck, industrial, powersports and utilities markets. One of its four facilities, in Sabina, OH, has committed to automation and currently utilizes cobots on several of its production lines to economically improve efficiency, accommodate labor shortages and reduce operator fatigue. As a result, the facility has realized numerous improvements—from production and quality to packaging and logistics.

Joining our automation panel discussion is company president Chris Highfield, who will walk us through the plant’s cobot-tended lines and highlight the improvements achieved with the automation projects. In addition, Highfield will share the company’s approach to automation projects, and some best practices it has adopted along the way.

Speakers

Chris Highfield, President, Pennant, Inc.

Nick Laney, Director of Operations, Pennant, Inc.

Case Study #2: Argon Industries

Argon Industries’ employment of fabrication automation is second to none, including three turret punch presses outfitted with load/unload technology. The trio doubles throughput of three previous standalone machines. The Milwaukee, WI, fabricator has invested mightily to add automation for loading and unloading its stable of laser cutting machines and press brakes, and also has added robotic-welding capacity.

Joining our conversation: company founder and president Greg Clement. “We once had three standalone turret presses with no automation,” Clement says. “We needed one person per shift hoisting a sheet off of a skid and onto the worktable and then cutting parts off of the sheet all day. The monotony and fatigue were unhealthy. Now, instead of one person per machine per shift, the three machines together only require 1.5 operators per shift. Setup and loading/unloading are entirely automatic.”

Speaker

Greg Clement, Founder and President, Argon Industries

Sponsors

Principal Financial Network

View Glossary of Metalforming Terms

See also: Precision Metalforming Association, T&C Stamping Inc.

Technologies: Pressroom Automation, Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

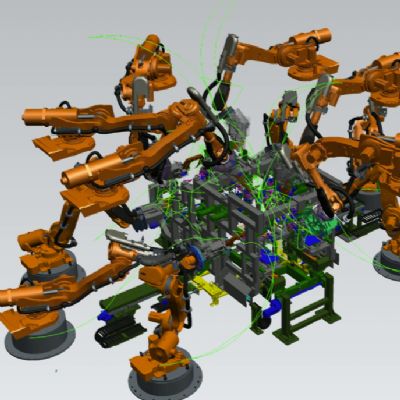

Pressroom AutomationRobot Versatility on Display at the Kuka Booth

Friday, June 27, 2025

Automatica Trend Index: Robots Welcome in U.S. Manufacturing...

Friday, June 27, 2025

Pressroom Automation

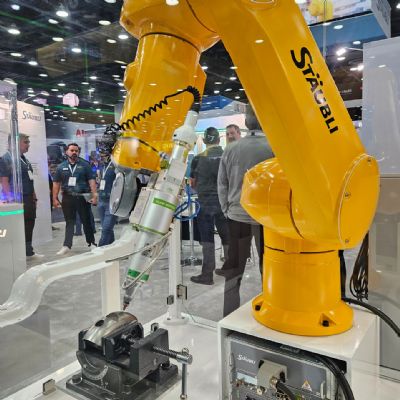

Pressroom AutomationStaubli Showcases Precision, Robotic Applications

Thursday, June 26, 2025

Pressroom Automation

Pressroom AutomationCloud-Based Rapid Robot-Motion Planning

Wednesday, June 25, 2025