AM Research at Clemson for U.S. Army to Employ 3D Systems Nine-Laser Printer

March 10, 2021Comments

Clemson University researchers are receiving funding from the U.S. Army Combat Capabilities Development Command (DEVCOM) Army Research Laboratory (ARL) to create new technology aimed at helping speed development of 3D-printed components for future ground vehicles, air platforms and munitions. The research will leverage a unique nine-laser metal-additive manufacturing (AM) system, featuring a 1 m by 1 m by 600-mm build chamber, developed for DEVCOM ARL by 3D Systems.

The Clemson researchers say that they will create a “digital lifecycle platform” augmented with artificial intelligence as part of the project. The idea behind the platform is to help production engineers more quickly and inexpensively design, analyze and fabricate a range of large and complex geometry components with embedded multi-functionalities, such as ground- and air-vehicle structures with power transmission, energy storage, sensing and self-monitoring functions, for achieving overall size, weight, power and cost efficiencies.

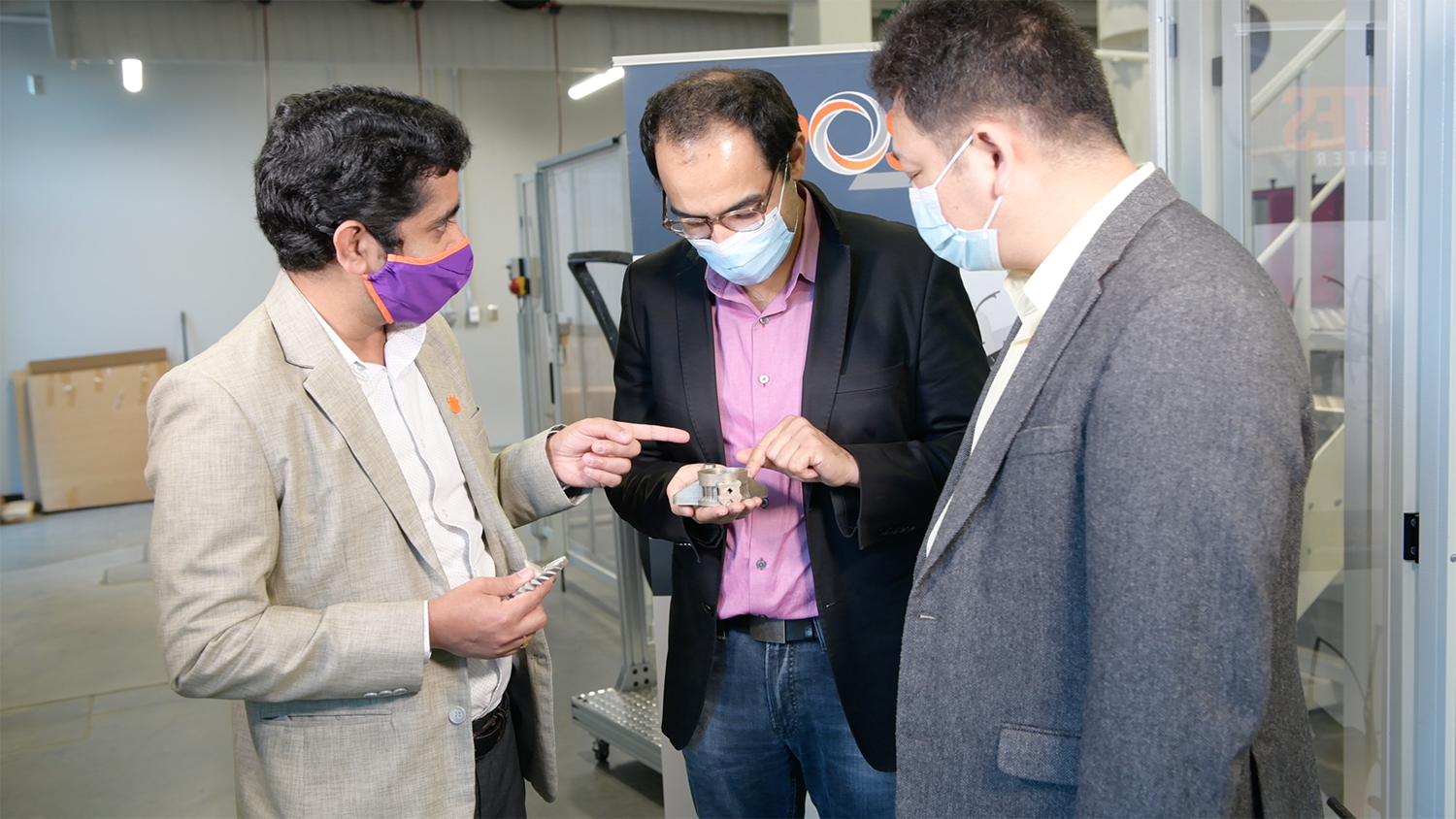

Clemson University project leaders Srikanth Pilla, Fadi Abdeljawad and Gang Li (left to right) as well as Shunyu Liu and Rahul Rai will drive research from the Clemson Composites Center in Greenville, SC, to create new technology aimed at helping speed development of 3D-printed components for future ground vehicles, air platforms and munitions for the U.S. Army. The research will leverage a unique nine-laser metal-additive manufacturing system, featuring a 1 m by 1 m by 600-mm build chamber, developed by 3D Systems. Image courtesy of Clemson University.

An $11-million cooperative agreement was established with DEVCOM ARL for this research, with first-phase funding totaling $6.3 million. Once fully developed, the platform would allow engineers to design and test new components without physically building them.

“This agreement is another example of Clemson’s growing emphasis on partnering with industry and the government to leverage the university’s research expertise to benefit our state and nation,” says Jim Clements, Clemson president. “I am very proud of the work being done by our faculty that will allow this cutting-edge technology to play an important role in the creation of next-generation vehicles and other vital equipment for our military.”