AM Systems Help ArcelorMittal Stock Spare Metal Parts

April 24, 2020Comments

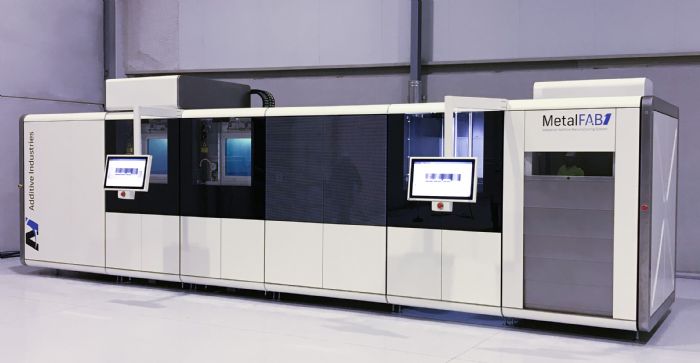

Steelmaker ArcelorMittal has been able to print on-demand ready-to-use spare parts courtesy of a collaboration with Additive Industries and use of Additive Industries’ four-laser MetalFab1 additive manufacturing (AM) system. 3D printing of spare parts offers on-demand, on-location production, which reduces the need for stocks, and also shortens the production cycle and affords flexibility to ArcelorMittal plants, according to officials from the steelmaker. Since the installation of the first metal 3D printer at ArcelorMittal R&D facilities in December 2017 (pictured is a machine installation at the steelmaker), several 3D-printed spare parts already have been used while others are still running.

Steelmaker ArcelorMittal has been able to print on-demand ready-to-use spare parts courtesy of a collaboration with Additive Industries and use of Additive Industries’ four-laser MetalFab1 additive manufacturing (AM) system. 3D printing of spare parts offers on-demand, on-location production, which reduces the need for stocks, and also shortens the production cycle and affords flexibility to ArcelorMittal plants, according to officials from the steelmaker. Since the installation of the first metal 3D printer at ArcelorMittal R&D facilities in December 2017 (pictured is a machine installation at the steelmaker), several 3D-printed spare parts already have been used while others are still running.

The MetalFAB1, reports Additive Industries officials, automates the manual steps of conventional powder bed fusion printers to provide high productivity. And, its build volume of 420 by 420 by 400 mm enables production of large steel spare parts for steelmaking or mining operations. The MetalFab1’s designed in safety features reportedly contribute to ArcelorMittal’s focus on operator safety as well as environmental goals, as the system recycles all material and generates little production waste.

See also: Additive Industries B.V.

Technologies: Additive Manufacturing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Additive Manufacturing

Additive ManufacturingMeltio and Phillips Collaborate on Hybrid CNC Machining and ...

Monday, June 9, 2025