The operator must work the deformed material flat before forming it, either through hand manipulation or rolling. If the deformation occurs in multiple directions, such as a simultaneous bow and a twist, don’t try to work the deformation out from multiple directions at once. Instead, work one direction first before moving on to the other.

A cost-effective way to remove the twisting is to press the twisted part against a jig made of wood or a set of flattening dies.

Fixing Long-Strip Bow

Typically, backgauges have two fingers, or stops. An operator moves these stops out to the farthest edges of a part to gain optimal rigidity during gauging. But forming long strips such as framing channels can present challenges. Often, the material is thin and the wide spread between the stops presents a ripe opportunity for an operator to press too firmly, bowing the workpiece. The bend line itself remains straight but the resulting bow in the workpiece will manifest in the flange as a tall center, only tapering down to the correct dimension at the stop location.

Typically, backgauges have two fingers, or stops. An operator moves these stops out to the farthest edges of a part to gain optimal rigidity during gauging. But forming long strips such as framing channels can present challenges. Often, the material is thin and the wide spread between the stops presents a ripe opportunity for an operator to press too firmly, bowing the workpiece. The bend line itself remains straight but the resulting bow in the workpiece will manifest in the flange as a tall center, only tapering down to the correct dimension at the stop location.

To remedy this, you might simply add a third stop in the center. That equalizes the gauging pressure across the workpiece, right? Almost. Any bow in the blanks can still present a gauging issue. A blank bowed away from the center stop only requires some extra pressure in the center to touch. But a blank bowed toward the center will touch the stop early, pushing one of the end stops away. Depending on part length, this now may become a two-person operation to ensure that both ends and center are held against the stops.

Fixing Overbent Angles

Run a brake long enough and you are sure to overbend an angle. It happens. Depending on machine and tooling geometry, overbending may not be a big deal. You may simply be able to flip the part over and unbend it manually. Note that this cannot be done if the power flowing through the machine and the part are offset, such as with 2V dies. If that’s the case, flipping the part may result in part slippage and personal injury.

Run a brake long enough and you are sure to overbend an angle. It happens. Depending on machine and tooling geometry, overbending may not be a big deal. You may simply be able to flip the part over and unbend it manually. Note that this cannot be done if the power flowing through the machine and the part are offset, such as with 2V dies. If that’s the case, flipping the part may result in part slippage and personal injury.

Using an upside-down large-radius punch and mallet will correct the overbend. This creative approach requires some blood, sweat and tears, but prevents the signature dent on the outer edge.

The outermost edge forms from the initial bend, so when the punch contacts the outside radius, it will leave a signature dimple.

Often, sliding witness marks appear on the inside radius from the lower die at the contact point of the radius. Reduce these marks using brake die film.

The last, desperate but sometimes effective method to correct an overbend is to knock the part on the table. Sometimes all you need to do in order to adjust for a little material variation on a long run is a quick whack. As silly as it sounds, a quick tap on the outside radius of a firm surface can sufficiently move the angle of a flange.

Fixing Side Blowout

A side stop or side gauge keeps short-bend-length parts perpendicular (or otherwise) to the bend line. Watch for material-edge deformation on successive bends. Blowout on the side of a bend may occur at the point of contact between the workpiece and the side stop. The effect is a perpendicular first bend and a slightly out-of-square second bend.

A side stop or side gauge keeps short-bend-length parts perpendicular (or otherwise) to the bend line. Watch for material-edge deformation on successive bends. Blowout on the side of a bend may occur at the point of contact between the workpiece and the side stop. The effect is a perpendicular first bend and a slightly out-of-square second bend.

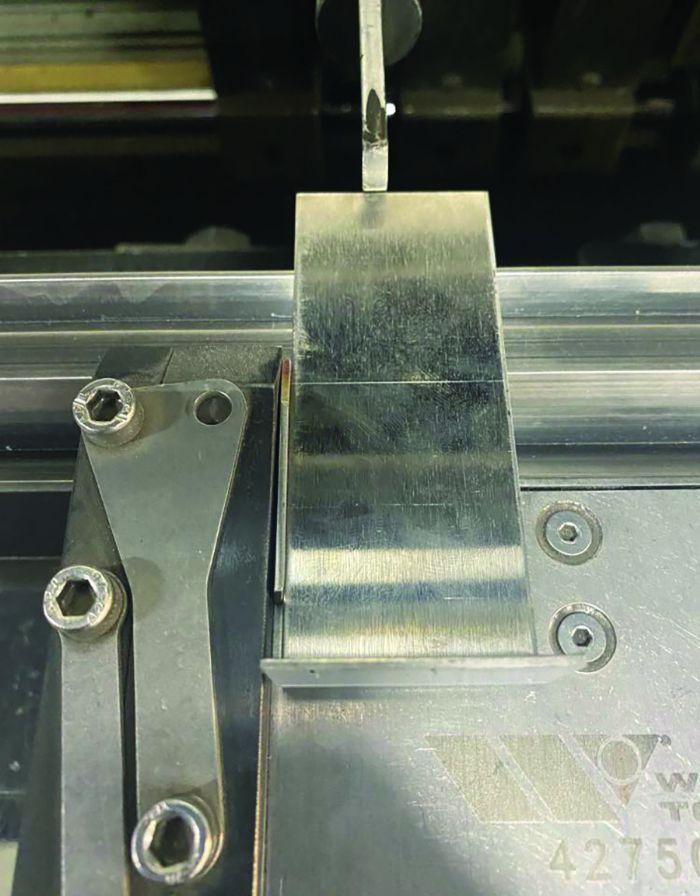

A quick remedy to mitigate side-stop blowout is to stack another square bar against the side stop.

Lean on Experienced Operators, Custom Fixes

There is no one right way to fix all defects. Many tricks of the trade have arisen from whatever “tool” was available in the shop at the time, and many experienced senior operators have custom-fixed more than a few parts. This has led to revisions of these processes over time. Take a few minutes to approach some of the most experienced press brake operators in your shop and ask for their input before hammering away. They have unique insights from trial and error. Experience is often what you find when looking for something else. MF

Creative Approaches to Common Press Brake Challenges, Part 1: Step Bending

Creative Approaches to Common Press Brake Challenges, Part 2: Managing Feature Deformation

Creative Approaches to Common Press Brake Challenges, Part 3: Self-Inspection at the BrakeView Glossary of Metalforming Terms

Technologies: Bending

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingBLM Group USA Names Adelman Head of Product Group

Friday, May 16, 2025

Bending

BendingBLM Group Names Israel Arenas Product Specialist for Press B...

Thursday, February 20, 2025

Bending

BendingCreative Approaches to Common Press Brake Challenges, Part 3...

Justin Talianek Friday, January 31, 2025

If you’ve gauged and inspected bent parts and found deviations beyond the allowable range, try to fix them before they head to the quality-assurance (QA) department. Here are some potential fixes to errors found upon inspection at the brake:

If you’ve gauged and inspected bent parts and found deviations beyond the allowable range, try to fix them before they head to the quality-assurance (QA) department. Here are some potential fixes to errors found upon inspection at the brake: Confirm that the blank is flat and that the overall blank size is accurate before proceeding to form it. Once a part is bent, there is no turning back time to measure the flat blank. Confirming the blank size before forming eliminates the possibility of bending a nonconforming blank and offers an opportunity to adjust the dimensions into tolerance.

Confirm that the blank is flat and that the overall blank size is accurate before proceeding to form it. Once a part is bent, there is no turning back time to measure the flat blank. Confirming the blank size before forming eliminates the possibility of bending a nonconforming blank and offers an opportunity to adjust the dimensions into tolerance.