Cost Savings

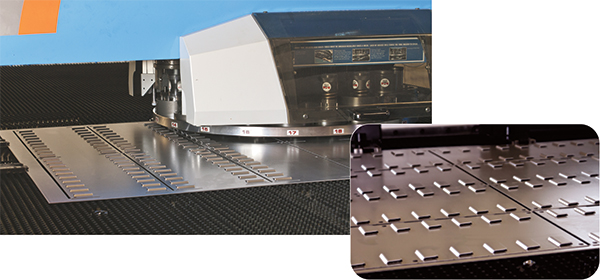

“We produce a tremendous amount of louvers for hanging bins, etc., all of which we were outsourcing to local vendors,” explains Redmon. “The E6x allows us to produce all of the louvers inhouse, saving us nearly $1 million.

“It also allows us to decrease our prototyping time,” he continues. “Traditionally, to bring a new product to market took us 6 to 10 weeks of prototyping time. Now we can turn those parts around the next day.

“The E6x also gives us flexibility in how we choose to manage our inventory,” adds Redmon. “We’ve reduced our inventory from three months’ worth down to three weeks’ worth.”

Bring on the Servo-Electric Brake

Just six months after purchasing its servo-electric turret punch press, Jamco added a servo-electric press brake to its equipment arsenal—a Prima Power eP model. The eP-series press brake, part of Prima’s “Green Means” eco-friendly concept for sustainable manufacturing, delivers sustainability, manufacturing efficiency and productivity, say company officials. It also means greater versatility compared to hydraulic press brakes, with reduced power consumption and maintenance costs. The net result, says Redmon: the ability to form higher-quality sheetmetal parts at an overall lower cost.

“We had very old hydraulic press brakes,” Redmon says. “Purchasing the eP press brake increased our productivity and flexibility, and our ability to efficiently form complex parts.

“For example,” he continues, “some of our stainless-steel cabinets have some unique top and bottom trays. Thanks to the press brake’s capabilities, we now can bend these parts inhouse. The press brake gives us flexibility in how we bend complex shapes, and increases the speed at which we can bend. We’re also achieving tighter tolerances, which improves fitup and makes it easier for our welders, which translates into higher productivity.

“Our new servo-electric equipment has brought Jamco into the 21st century,” concludes Redmon. “The turret punch press and press brake have increased our productivity, flexibility and accuracy, helping to bring Jamco to the next level.” MF

Article provided by Prima Power North America, Arlington Heights, IL: 847/952-6550, www.prima-na.com.View Glossary of Metalforming Terms

See also: Prima Power North America, Inc.

Technologies: Bending, CNC Punching