400,000 Holes Later

McDonald does the math:

“Since launching the job, we’ve made nearly 400,000 tapped holes—that would have been an unwieldy amount of secondary operations, creating tremendous material-handling challenges throughout our shop.”

He also notes that the tapping tool forms the threads—“it’s not a cutting tool,” McDonald stresses, “so we don’t get material shavings in the machine or burrs pushing out of the backside of the parts.”

And, according to Wilson Tool officials, thread-forming taps create 30%-stronger tapped holes when compared to conventional cutting taps.

“The tapping tool is really a ‘machine within a machine,’” explains Wilson Tool sales engineer Hector Velazquez. “The user specifies the screw pitch required, and the hole sizes, then purchases the appropriate pitch insert that installs in the tapping tool, as well as the tap sizes that fit the specified pitch. The tapping tool has its own lubrication setup—an external lube tank and fluid-injection system that sends lubricant to the tapping tool with every stroke of the turret press. A full lube tank should last for about 40,000 taps.”

In the case of Precision Machine, “we’re using just one combination of pitch insert and tapping tool,” McDonald says. “All of the holes, so far, have been 10-32. We’re tapping at about 150 holes/min., and each insert is good for around 2500 holes before we have to change tips.”

In the case of Precision Machine, “we’re using just one combination of pitch insert and tapping tool,” McDonald says. “All of the holes, so far, have been 10-32. We’re tapping at about 150 holes/min., and each insert is good for around 2500 holes before we have to change tips.”

Velazquez imparts one piece of advice for shops interested in adding the QuickTap tool to their libraries: “The tool requires attention to maintenance and upkeep. Users, in addition to checking the lube tank and ensuring that there’s always fluid available, must maintain a clean workspace, as the tapping mechanism can be sensitive to dirt and dust. It requires clean oil and clear fluid hoses—basic stuff. But the payoff when using the technology to eliminate tapping as a secondary operation is significant. Shops avoid the added costs associated with secondary ops—wait time, movement of materials, etc., and sidestep what can become significant production bottlenecks, enabling them to deliver shorter lead times for customers.”

Tooling Options Beget Versatility

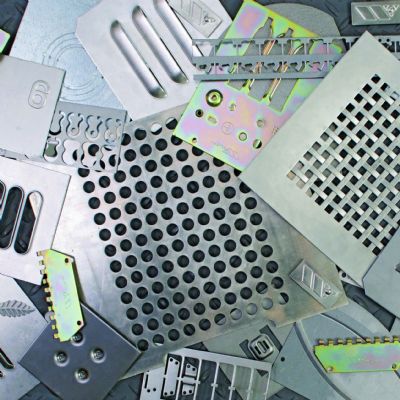

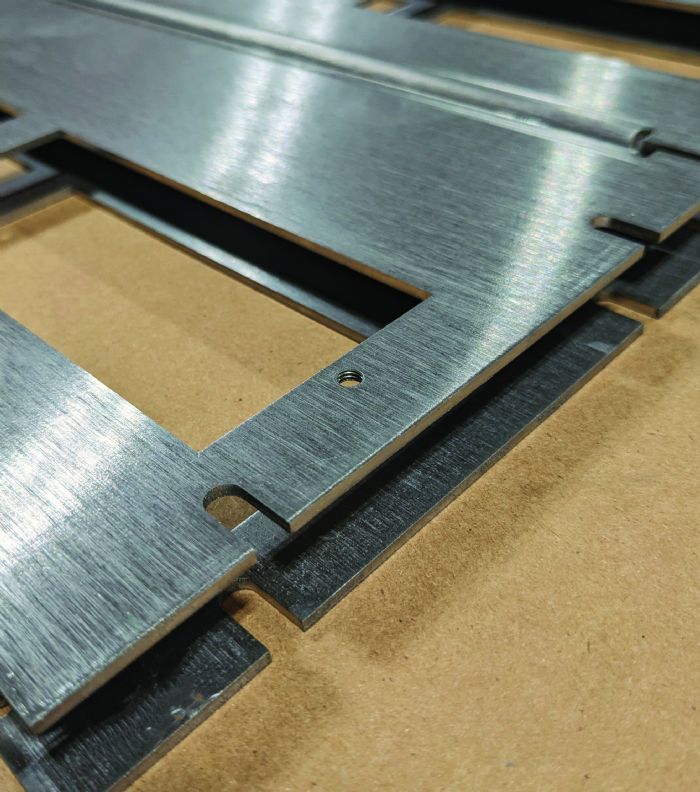

Per Amada, the EM2510NT boasts an AC servo-direct twin-drive system that delivers a maximum 500 hits/min. on 1-in. centers. Its 100-in.-X-axis table enables processing of 8-ft. sheets without repositioning. And, its 0.984-in. turret feed clearance enables forming to nearly a 1-in. flange. To the tooling experts at Wilson Tool, the application at Precision Machine Fabrication represents well the versatility of CNC turret presses, capabilities often not well understood among sheet metal fabricators.

“While lasers and press brakes are the razzle-dazzle,” says Wilson Tool punching product manager Susan Erler, “CNC punch presses can provide a great deal of functionality, and tapping is a good example of that. Another is tooling for flange forming, which in many cases allows fabricators to forgo a secondary operation on a press brake. We even have marking tools that allow fabricators to mark bend lines or assembly instructions on their punched parts, and a hinge-forming tool that door manufacturers appreciate.

“While lasers and press brakes are the razzle-dazzle,” says Wilson Tool punching product manager Susan Erler, “CNC punch presses can provide a great deal of functionality, and tapping is a good example of that. Another is tooling for flange forming, which in many cases allows fabricators to forgo a secondary operation on a press brake. We even have marking tools that allow fabricators to mark bend lines or assembly instructions on their punched parts, and a hinge-forming tool that door manufacturers appreciate.

“Lead time is everything to contract fabricators,” Erler continues, “and these value-added capabilities help users reduce their lead times and open up new capabilities, expanding their breadth of work.”

McDonald couldn’t agree more, noting that Precision Machine Fabrication’s reputation as a “problem solver” for its customers has led to consistent growth. What began in 1978 in a small 1000-sq.-ft. rented storage space, launched by two employees (off-duty Raleigh firemen), now occupies 60,000 sq. ft., including a 4000-sq.-ft. paint shop, and 40,000 sq. ft. of warehouse space to accommodate customer-stocking programs.

Among the equipment on the Precision Machine Fabrication shop floor, in addition to the Amada EM 2510NT: three stand-alone laser cutting machines, two punch-laser combination machines and three new CNC press brakes added in 2023. The firm also houses a CNC machine shop, performs assembly operations, and provides gas-metal- and gas-tungsten-arc welding.

“We acquired the new press brakes so that we now can pre-program our bending operations through our engineering department, similar to our process for CNC punching and laser cutting,” McDonald says. He estimates that this process has reduced press brake setup time by 70%, as programmers now fine-tune and test any new bending procedures in CAD prior to sending a new job to the shop floor.

More Creative Tooling Solutions

The fabricator, in addition to continuously learning how to optimize machine and department throughput, also has found some secrets to allow the punching and bending processes to meld together more seamlessly. Again, it comes down to creative tooling solutions.

“A customer recently came to us with yet another challenging part,” McDonald explains, “embossed in two directions—one formed up, the other formed down. One of the embossed features was located too close to the bend line to enable repeatable forming on the press brakes, while maintaining a nice cosmetic edge to the part.”

The solution, he explains: “Use of an extruded countersink tool on the turret press, enabling us enough room between the bend line and the embossment to form the part in the press brake.” McDonald notes that the firm also equips its turret presses with several forming tools, including tools for forming louvers, lances and knockouts.

Bottom line: The extensive tooling library at Precision Machine Fabrication, including specialized tools such as the QuickTap and extruded countersink tool, helps the firm win new customers and create new capabilities. “And, in many instances,” adds McDonald, “we’re eliminating secondary operations, running jobs in just a matter of hours that otherwise would take several shifts.” MF

View Glossary of Metalforming Terms

See also: Amada North America, Inc, Wilson Tool International

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsPunching Through the Barriers: Processing Advanced High-Stre...

Saturday, March 29, 2025

CNC Punching

CNC PunchingScotchman Industries Names Kent Bradley Director of Marketin...

Tuesday, February 25, 2025

That’s the thinking of Precision Machine Fabrication project manager Doug McDonald, who also heads up the firm’s estimating department. He tells MetalForming:

That’s the thinking of Precision Machine Fabrication project manager Doug McDonald, who also heads up the firm’s estimating department. He tells MetalForming: