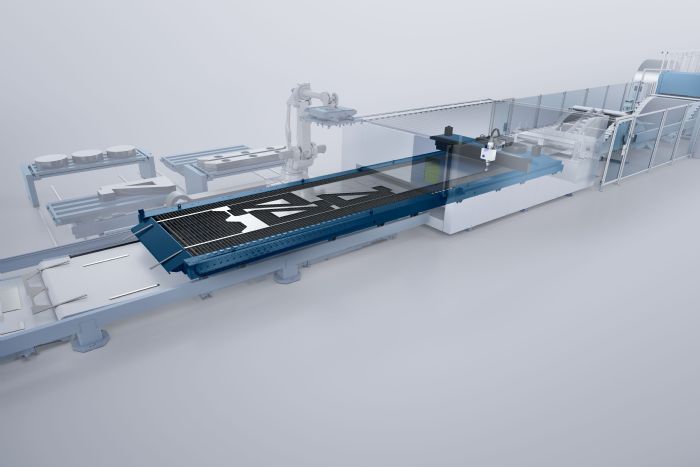

Laser Blanking Enables Straight-From-the-Coil Production

June 9, 2023Comments

Trumpf Inc. Booth A2104

Now available in North America, the TruLaser 8000 Coil Edition can process as much as 25 metric tons of coiled sheet metal from start to finish without human intervention. It is a viable option for companies interested in flexible, high-volume cutting solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers, and HVAC manufacturers.