Wavelength

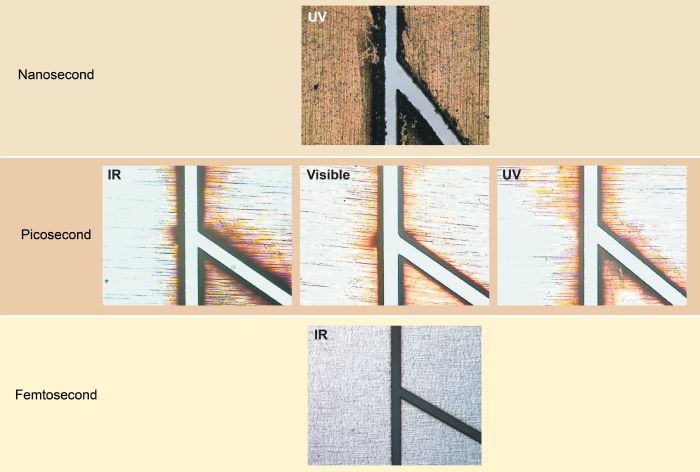

While every material has its own unique absorption spectrum, in general, all metals reflect relatively well in the infrared, and absorb more strongly at shorter wavelengths. As a reminder, infrared (IR) light has a longer wavelength than visible light, which is, in turn, longer in wavelength than ultraviolet (UV) light. So, cutting efficiency typically is worst in the IR spectrum, and increases at shorter wavelengths. Plus, the strong absorption of UV light means that it doesn’t penetrate far into the material, which minimizes the HAZ.

Another important factor in wavelength: Shorter-wavelength

lasers can be focused to smaller spot sizes (the equivalent to using a smaller-diameter

drill or narrower saw blade). This further enables the production of finer

features.

Another important factor in wavelength: Shorter-wavelength

lasers can be focused to smaller spot sizes (the equivalent to using a smaller-diameter

drill or narrower saw blade). This further enables the production of finer

features.

But, guess what? Pulsed DPSS lasers all produce IR light,

and getting shorter wavelengths out of them involves special optics that

increase cost and reduce output power. So, in general use the longest wavelength

that gets the job done because higher power is more readily available, and the

cost per Watt is lower.

Power

DPSS lasers for materials processing virtually always are used

in a pulsed mode, rather than in a continuous wave where laser output remains

constant over time. The laser outputs a series of light bursts, and pulse

length refers to how long each burst lasts.

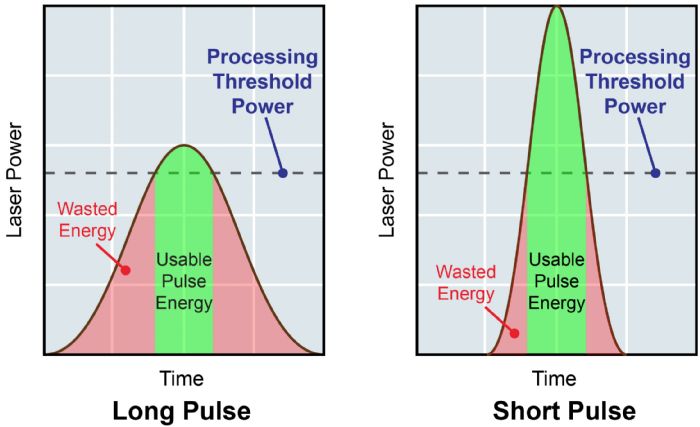

For pulsed lasers, the term power really refers to the combination of pulse energy and repetition rate (pulse energy × repetition rate = average power). For a given pulse energy, decreasing the pulse length, or pulse duration, increases the peak power.

Each material features an ablation threshold—a certain minimum pulse energy required to produce material removal, rather than just bulk heating. If the pulse energy isn’t higher than the ablation threshold for the material, the workpiece will be heated but no material removal will occur. Should the pulse energy be too high, not all of the laser energy is used efficiently for material removal, and bulk heating and the resulting HAZ again will occur. There’s typically a sweet-spot maximum material-removal rate for most metals that occurs when laser peak power reaches seven to ten times the material-ablation threshold (Fig. 1).

Once the optimum pulse energy is determined, throughput (material-removal rate) may be increased by increasing the pulse-repetition rate. However, this action impacts other aspects of system operation, in particular the scanning speed or table speed. It’s usually necessary to have the laser beam move rapidly enough across the work surface to avoid a significant amount of pulse overlap. However, when operating at the optimum material-removal rate doesn’t produce a cut at the necessary depth, multiple passes or some pulse overlap may be necessary.

Pulse Length

Longer-pulse commercial DPSS lasers commonly employ a pulsing technology called “q-switching,” which delivers pulse lengths in the nanosecond range (10 to 9 seconds or a billionth of a second). But, these lasers can be designed to produce pulse lengths in the picosecond (10 to 12 seconds) or even femtosecond (10 to 15 seconds) range.

Longer-pulse commercial DPSS lasers commonly employ a pulsing technology called “q-switching,” which delivers pulse lengths in the nanosecond range (10 to 9 seconds or a billionth of a second). But, these lasers can be designed to produce pulse lengths in the picosecond (10 to 12 seconds) or even femtosecond (10 to 15 seconds) range.

Generally, shorter pulse lengths deliver a smaller HAZ. Furthermore,

the impact of decreased pulsewidth generally is much more dramatic than that of

decreased wavelength for a couple of reasons.

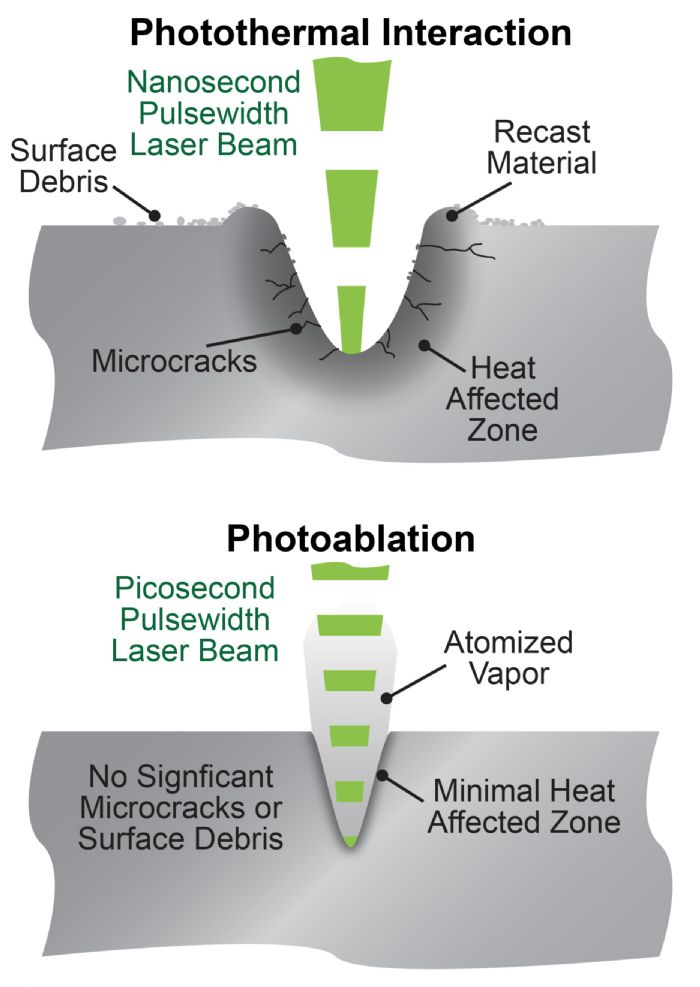

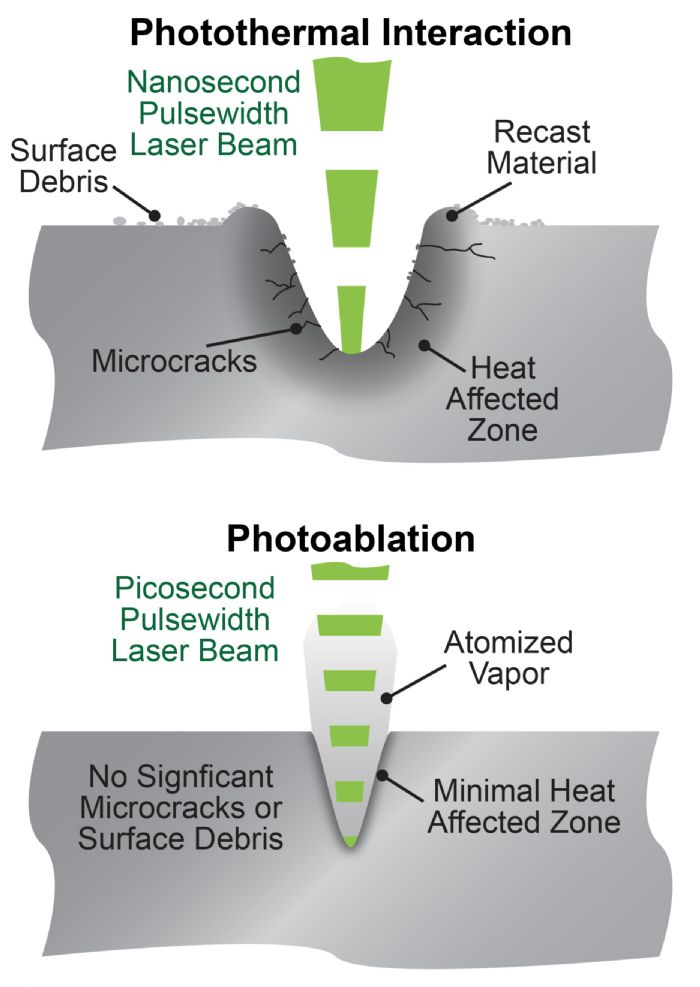

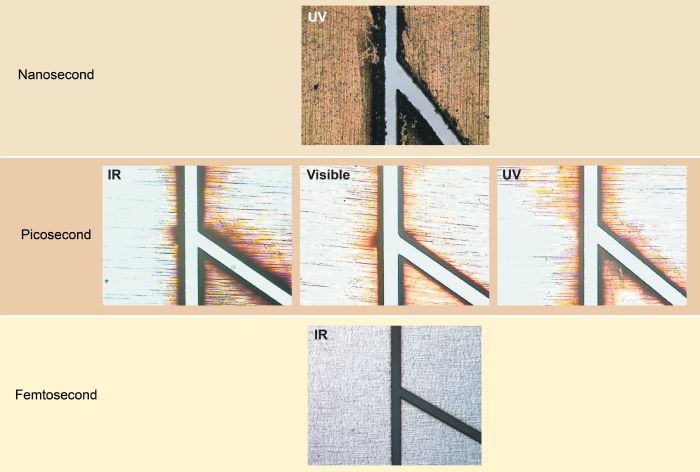

First, nanosecond pulse lengths tend to remove material by thermal means—heating the material until it boils off. But, at shorter pulse lengths (especially below 1 picosecond), another mechanism called photoablation starts to occur.

In photoablation, the use of very short pulse lengths produces very high peak fluences that can directly break the molecular or atomic bonds holding the material together, rather than simply heating it. Plus, with the material exposed to the laser energy for such a short time, the energy can’t be carried beyond the area of impact, thus the surrounding area stays cold. Energy remaining after the bond-breaking process is carried away with the expelled particles. Together, these effects result in an inherently colder process with a significantly reduced HAZ (Figs. 2 and 3). Plus, as a very clean process, photoablation leaves no recast material, thereby eliminating the need for elaborate post-processing.

But, making DPSS lasers operate at shorter pulse lengths

(called ultrashort pulse, or USP) requires more system complexity, and,

therefore, greater cost. Thus, cost/part versus feature necessity should be

weighed. With this in mind, USP lasers generally are reserved for the most

demanding tasks where precision is absolutely critical. USP lasers also enable

machining of traditionally difficult materials such as glass, ceramics,

sapphire and diamond.

Help With Particular Applications

Most manufacturers seek to achieve the most cost-effective process. Besides laser purchase and operating costs, many other factors play into this, including throughput, scrap and rework rates; and consumables costs (e.g. assist gas). It’s a relatively large parameter space to explore, making assistance from the laser supplier or systems integrator a practical matter. Specifically, it can be helpful to partner with a supplier for some applications development, particularly on the workpiece material. Ideally, the supplier should have a variety of different laser sources available in order to determine a best choice for a given application. In the best case scenario, the supplier may even develop an optimum process recipe for the specific application need. MF

Author’s Note: An excellent treatment of this topic can be found in Fundamentals of Laser MicroMachining, a book by Ronald Schaeffer, Ph.D. The author wishes to thank Dr. Schaeffer for his assistance in the preparation of this article.

See also: Coherent, Inc.

Technologies: Cutting

For the purposes of this discussion, precision cutting or microstructuring refers to the production of features in a material on the scale of 25 µm or less. Depending upon substrate thickness, a common aspect ratio is 10:1. These scale features are produced on metal substrates from 1 mm thick to thin foils of less than 10 µm thick.

For the purposes of this discussion, precision cutting or microstructuring refers to the production of features in a material on the scale of 25 µm or less. Depending upon substrate thickness, a common aspect ratio is 10:1. These scale features are produced on metal substrates from 1 mm thick to thin foils of less than 10 µm thick.

Another important factor in wavelength: Shorter-wavelength

lasers can be focused to smaller spot sizes (the equivalent to using a smaller-diameter

drill or narrower saw blade). This further enables the production of finer

features.

Another important factor in wavelength: Shorter-wavelength

lasers can be focused to smaller spot sizes (the equivalent to using a smaller-diameter

drill or narrower saw blade). This further enables the production of finer

features.  Longer-pulse commercial DPSS lasers commonly employ a pulsing technology called “q-switching,” which delivers pulse lengths in the nanosecond range (10 to 9 seconds or a billionth of a second). But, these lasers can be designed to produce pulse lengths in the picosecond (10 to 12 seconds) or even femtosecond (10 to 15 seconds) range.

Longer-pulse commercial DPSS lasers commonly employ a pulsing technology called “q-switching,” which delivers pulse lengths in the nanosecond range (10 to 9 seconds or a billionth of a second). But, these lasers can be designed to produce pulse lengths in the picosecond (10 to 12 seconds) or even femtosecond (10 to 15 seconds) range.