Motion-Control Tuning Wizardry

In the upgraded saw, the new motion controller directs a Parker hydraulic cylinder that moves the anvil clamp, pushing it toward the saw blade. After each cut, the clamp releases and the motion controller directs the clamp frame to move back for the next push.

“When you’re fighting downtime, support is a big deal,” says Marion. “We had some issues with connecting to a linear transducer, and Delta’s support crew went above and beyond in helping us resolve the issue.”

|

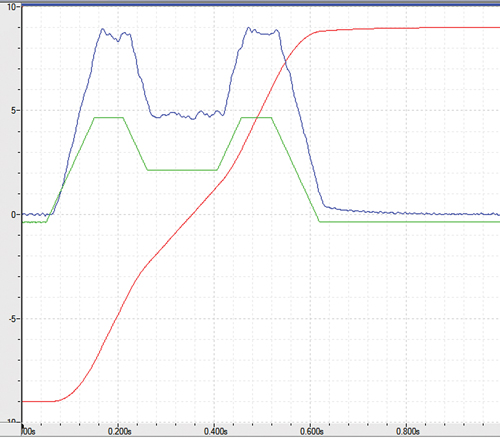

| Delta’s RMCTools Plot Manager generates a plot that displays target and actual motion profiles. The red plot line represents the actual position of the clamp frame, overlaid precisely on the target position (cyan). The blue line represents actual axis velocity, overlaid precisely on the target profile (magenta). The green curve represents the drive signal to the hydraulic valve. |

The Tuning Wizard automatically builds a mathematical model of the system being controlled, and allows the user to select via an on-screen slider bar the level of responsiveness needed in the control loop.

“We just had to move the slider and push the button on the screen,” says Marion. “We’re holding a tolerance on that old saw of ±0.001 to 0.003 in., and all we changed was the controller.”

By repeatably cutting billets to such tight tolerances, Catalina Cylinder has been able to eliminate a potential source of wasted aluminum. Other savings come from a reduction in downtime for maintenance.

Setup and Operation

The motion controller gets its instructions from a PLC, which in turn is set up by an HMI screen developed by Catalina Cylinders.“Before the upgrade,” says Marion, “programming the machine with the old controller was a chore. Now, the HMI enables setup in less than one minute.”

To verify precise tuning of the anvil-clamp control loop, Catalina Cylinder employs the Delta Computer Plot Manager program, provided as part of its RMCTools motion-control software package. “Target and actual motion profiles are plotted,” explains Marion, “and when the actual value of a parameter precisely overlays the target value at all points in time, we know that we’ve properly tuned the system.”

“Equipment obsolescence presents potentially big problems in the industry,” concludes Eschborn. “By retrofitting motion systems with new state-of-the-art controls, we can give old machines new life.” MF

See also: Delta Motion

Technologies: Cutting, Sensing/Electronics/IOT

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingSMX Industrial Solutions Welcomes Neal Glassett as Vice Pres...

Tuesday, February 13, 2024

Cutting

CuttingAll-Purpose Bandsaw Blades Cut a Variety of Steels

Friday, January 19, 2024