To revamp this process, GEA developed the zero-distance approach—zero distance (time) between design releases, starting from early milestones, and assessments of their manufacturability, with such assessments being executed internally at GEA by manufacturing experts using state-of-the-art digital tools.

Focused on

Formability and Feasibility

The revamped design process in place at GEA bypasses all of the redundant exchanges between the design and die-shop teams for a variety of GEA products. They set up a simulation team at GE Appliance Park in Louisville, KY, tasked with analyzing part designs with formability and feasibility in mind before product designs were released for manufacture.

The design team’s responsibilities remain largely the same, working either from Appliance Park or other locations. And while this team still designs parts with a focus on appliance appearance and functionality, part designs now go through the simulation team for formability before being released to the die shop.

The design team’s responsibilities remain largely the same, working either from Appliance Park or other locations. And while this team still designs parts with a focus on appliance appearance and functionality, part designs now go through the simulation team for formability before being released to the die shop.

The simulation team, then, acts as the bridge

between the design team, tooling engineers and the die shop. They receive parts

from the design team(s) and analyze them for problematic features. Their job primarily

is dealing with Class A parts, as they are the most challenging to manufacture,

but they also occasionally work on interior parts. Simulation-team members have

a background in tooling and therefore can recommend process changes if needed.

Software for Process Layout and Simulation

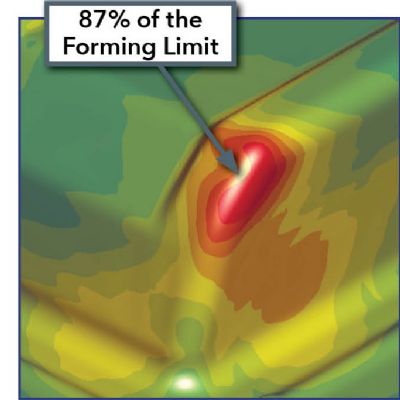

The GEA simulation team uses AutoForm software to evaluate

proposed part designs by developing a process layout and running simulations to

confirm design feasibility in the context of the proposed process. They already

may know the intended press line for a part and work to ensure that the part can

indeed be produced on that press line. If they find design inconsistencies or

process limitations, they go back to the design team. Using AutoForm, they

explain all of the hotspots and features requiring modifications, and why they

are necessary.

The design team, then, will either make the recommended modifications themselves or allow the simulation team to do so. This guided modification process eliminates needless communication between the design team, tooling engineers and die shop, and considerably reduced the time needed to develop and release parts that can be manufactured to GEA’s stringent quality standards.

On to the Die Shop

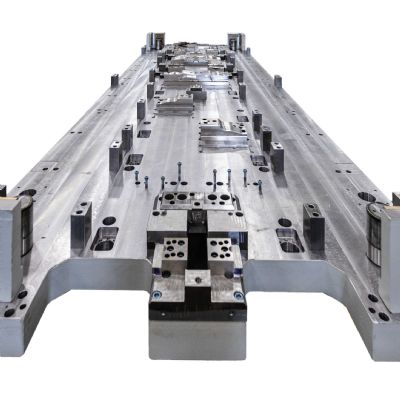

Once the simulation, tooling, and design teams have developed an

acceptable part design, they release the design to the die shop for tooling quoting,

design and build. At GEA, the die shops must perform further detailed formability

analyses and develop the final process layout based upon the initial general guidance

of the simulation and tooling teams. These detailed secondary analyses ensure that

released designs and finalized processes conform to the die-shop requirements, so

that they can take ownership of the manufacturing process layout.

Note: The GEA awarded die shop has never had to make major changes, such as modifying the material type, since the simulation team already has completed as much as 90 percent of the upfront work, including geometric dimensioning and tolerance assessments. And it also has applied very tight margins on safety, thinning and other quality metrics to ensure seamless assembly along with manufacturing. This largely has eliminated late-stage surprises at the die shop during confirmation analyses—or worse, during tryouts. That said, the die shop still can make small changes, such as optimizing blank size or adjusting draw-bead height and configuration for the right pressures.

Thus, the simulation team plays a key role in expediting the

manufacturing process. It coordinates with tooling and design engineers to

achieve a product with optimum appearance while staying within the limits of

the processes and other fixed factors.

Benefits of the Newly Refined Development

Process

GEA’s newly developed zero-distance process delivers unprecedented benefits compared to the traditional process.

This new process makes the entire workflow for design and

manufacture more cohesive and systematic. The die shop can take the released part

design and immediately begin to cut the steel, build the tool and initiate tryout,

all in a shorter time frame.

The time needed to carry out the extended interactions between the design and die-shop teams often is underestimated. When the die shop receives only a dimensioned part model and must work with the Tooling Engineers and product designers to make a change—a radius change on the part, for example—that process can take a long time. However, outlining the entire process, in minute detail, can save weeks or even months of time needed to move from the concept phase on to production. GEA estimates at least a 50-percent time savings compared to the traditional process.

The GEA team builds what was validated over the simulation-centered

process. This has reduced scrap and increased throughput, ultimately improving

financial margins. The man-hours saved on each project also translate to

considerable gains.

Bottom line: By doing 90 percent of the engineering work up front results in a minimum 50-percent overall time savings. MF

See also: AutoForm Engineering USA, Inc.

Technologies: Software

GE Appliances (GEA), a Haier company, has undergone sweeping internal transformation since 2016, driven by a “zero distance” strategy: zero distance between what the company makes and what its customers want; between ideas and innovation; and between where products are developed and made. Toward that end, GEA has transformed its business model toward a seamless and digital supply chain—internally and externally.

GE Appliances (GEA), a Haier company, has undergone sweeping internal transformation since 2016, driven by a “zero distance” strategy: zero distance between what the company makes and what its customers want; between ideas and innovation; and between where products are developed and made. Toward that end, GEA has transformed its business model toward a seamless and digital supply chain—internally and externally.

The design team’s responsibilities remain largely the same, working either from Appliance Park or other locations. And while this team still designs parts with a focus on appliance appearance and functionality, part designs now go through the simulation team for formability before being released to the die shop.

The design team’s responsibilities remain largely the same, working either from Appliance Park or other locations. And while this team still designs parts with a focus on appliance appearance and functionality, part designs now go through the simulation team for formability before being released to the die shop.