That material is called ZAM, which, per Wheeling-Nippon, is a “corrosion-resistant hot-dip zinc-aluminum-magnesium alloy coated-steel sheet product that exhibits exceptional alkaline resistance, even in direct contact with concrete and mortar.” The material meets ASTM A1046/A1046M Type 1.

More Prog. Dies Necessitates More Die Protection

Most work moving through the GSM pressroom runs through progressive tooling—not the case until the last 20 yr. or so. The move away from hand-fed blanks began at GSM around 2003, as it started to acquire larger, higher-tonnage presses. Says Hawkins: “As we added presses and moved more into progressive tooling, our need for die protection grew. However, over the years we found it difficult, with older press controls, to add the level of die protection we wanted.”

Hence the move, 5 yr. ago, to upgrade its press controls. “We build about 40 new tools each year, and every one of them now has die protection built in,” says Jonathan Stough, stamping department manager. “And, we’ve retrofitted just about every existing die with additional sensors. For dies that run infrequently, we use magnets to fit sensors to the press bolsters. The SmartPac 2 controls really simplify the process of implementing die protection.”

Hence the move, 5 yr. ago, to upgrade its press controls. “We build about 40 new tools each year, and every one of them now has die protection built in,” says Jonathan Stough, stamping department manager. “And, we’ve retrofitted just about every existing die with additional sensors. For dies that run infrequently, we use magnets to fit sensors to the press bolsters. The SmartPac 2 controls really simplify the process of implementing die protection.”

Brent Ortman, stamping lead and certified machine skills instructor, recalls a time, prior to the press-control upgrade, where an operator stood by at every press as it ran, “just watching and ready to take action if something went wrong,” he says. “We no longer must do that, thanks to the added die protection and upgraded press controls. Now our operators primarily are responsible only for end-of-line stamped-part handling, and for assisting with changeovers.”

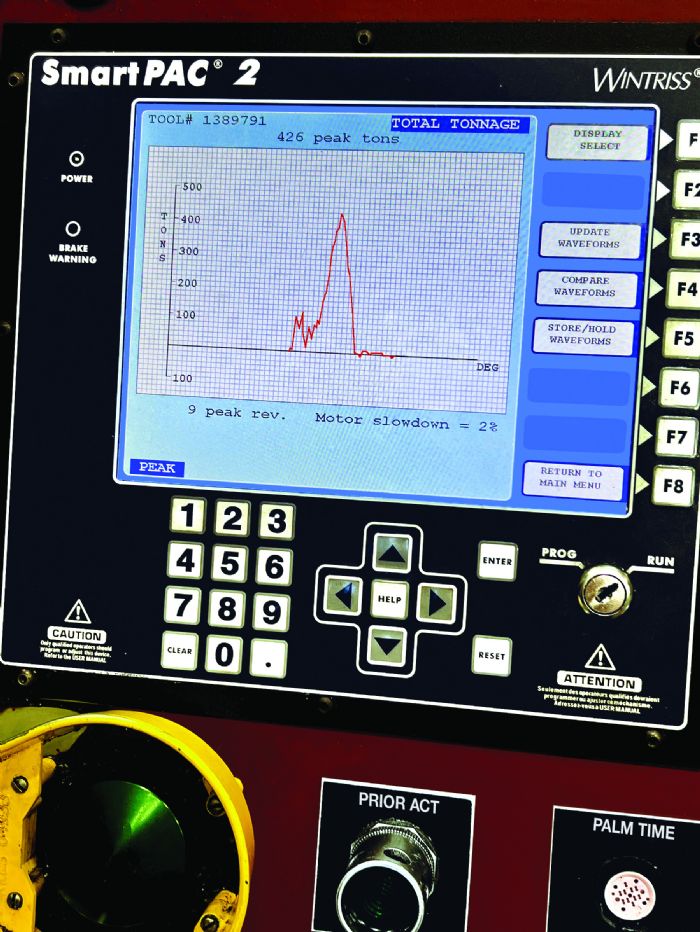

Also noted as an upgrade with its new controls: an upgrade to its tonnage monitoring capabilities. “Prior to installing the new controls, we would periodically experience tonnage-related quality issues,” Ortman says, “especially on thicker work requiring higher press tonnage. Now, any imperfection in the tool or the process and the press will stop before damaging the tooling or the parts.”

Quality Control is Cost Control

On the GSM website, this phrase caught my eye:

“Quality control is cost control,” and the press-control upgrade fits this bill. “Poor quality costs not only dollars and cents, but your reputation, and can damage customer relations,” Hawkins says. “From the feedback we receive from our customers, two things keep them coming back: quality and our customer service. We immediately address customer issues from a containment strategy internally, and we’ll even go to customers’ facilities and support them as needed. That’s why it’s critical that we error-proof our processes as much as possible up front.”

The senior management team at GSM reviews several key performance indicators at monthly senior-management meetings. Among them: overall equipment effectiveness (OEE), available to run, preventive-maintenance on-time completion, schedule attainment, on-time delivery and first-pass yield on repairs.

“Schedule attainment is averaging 95.7 percent for the last 6 mo.,” Hawkins shares, “and has remained within a percentage point or two each month. OEE for the press department has, for the last 6 mo., averaged 74 percent, and first-pass yield on repairs has stayed steady above the 90-percent goal.”

Visibility into the Presses and Processes

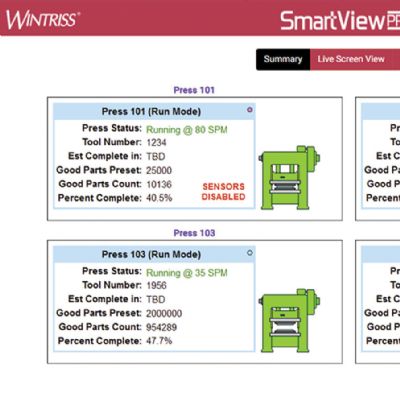

Along with the new SmartPac 2 controls, Wintriss also supplied GSM with its SmartView Network Interface, a Windows application that enables managers to view press status, production counts, press tonnage (when tonnage monitoring is active) and other information in real time, from networked SmartPac units on a Windows PC.

“Using SmartView, we instantly can see which presses are running and which are not,” Stough says, “and why. The application also calculates how far along a job is (generating a percentage) and how much longer the job needs to run until it’s complete. An event log displays a date- and time-stamped list of the last 200 events and any errors that occurred at each press control.”

Stampers also can use SmartView send short text messages to the press operators, displayed on the SmartPac screen as a “sticky” note, according to Wintriss, and recorded in the SmartPac error/event log.

“Being able to remotely monitor each press,” explains Ortman, “makes it easier to troubleshoot our production, especially during an off-shift where management may not be around. We can log in remotely, and even use Facetime to watch the press run, then go into the program and make any necessary adjustments, such as changing the timing of the die protection or of the feed line, rather than having to shut a press down and wait until the morning to address the issue.” MF

See also: Wintriss Controls Group LLC

Technologies: Pressroom Automation

That success comes in part from investing, in 2017, in a new 190,000-sq.-ft. manufacturing operation, along with upgrading the controls on 12 of its 15 presses, and, in 2022, acquiring and refurbishing a used 2000-ton press to expand its stamping capabilities. The new press controls support the firm’s efforts to boost its use of electronic die protection and press automation.

That success comes in part from investing, in 2017, in a new 190,000-sq.-ft. manufacturing operation, along with upgrading the controls on 12 of its 15 presses, and, in 2022, acquiring and refurbishing a used 2000-ton press to expand its stamping capabilities. The new press controls support the firm’s efforts to boost its use of electronic die protection and press automation.

Hence the move, 5 yr. ago, to upgrade its press controls. “We build about 40 new tools each year, and every one of them now has die protection built in,” says Jonathan Stough, stamping department manager. “And, we’ve retrofitted just about every existing die with additional sensors. For dies that run infrequently, we use magnets to fit sensors to the press bolsters. The SmartPac 2 controls really simplify the process of implementing die protection.”

Hence the move, 5 yr. ago, to upgrade its press controls. “We build about 40 new tools each year, and every one of them now has die protection built in,” says Jonathan Stough, stamping department manager. “And, we’ve retrofitted just about every existing die with additional sensors. For dies that run infrequently, we use magnets to fit sensors to the press bolsters. The SmartPac 2 controls really simplify the process of implementing die protection.”