VCI protection can function on high and low volumes of parts large and small. Take electrical connectors for example.

“Suppose a metalformer produces connectors from strip steel or copper or even silver-plated strip,” offers Simpson. “A strip of VCI paper can be fed onto a roll as an interleaf that delivers chemicals to the metallic parts. So as these finished connections are rolled into a coil, the thin strip of VCI paper feeds in with the coil and provides continuous protection throughout the length of that coil, ensuring corrosion-free parts throughout shipment and storage.”

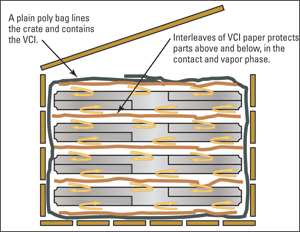

Fineblanked parts yield a more traditional mid-volume application, according to Simpson. “Consider the stamper that stacks several hundred fineblanked parts—about as large as your hand—into a bulk crate,” he says, “lined with a VCI bag. The bag, constructed of low-density polyethylene, is impregnated with VCIs that protect those parts that contact the bag as well as parts in proximity to the bag. Interleaves or paper or film VCI sheets may be added depending on the size of the crate, laid at intervals as the parts are stacked to ensure delivery of enough VCI to protect parts in the center of the crate. Just close the bag and crate for shipment. So, VCI packaging is not terribly different from what is done with conventional packaging materials.”

Part size represents no limitation for VCI applications, making the protection viable for large components and assemblies, and various alloys can be protected within a single bag. Attesting to those facts, Simpson notes that Daubert Cromwell has even wrapped complete engines for export.

“The engine is placed in a VCI bag along with one or two VCI emitters that add more chemicals for improved or prolonged protection,” he says. “The engine may have parts made from various alloys or featuring zinc-galvanized or phosphate coatings, and the engine block itself may be cast iron. All of those metallic species need protection within that bag, requiring a VCI composition that will actively protect each one. That may require a complex packaging design, with a number of VCI barrier layers along with VCI emitters placed inside the package.”

Some Homework Required

A VCI formulation functioning ideally under one set of conditions may not work under another, according to Daubert Cromwell officials. The success of a VCI application rests upon:

- Which materials are in need of protection;

- Corrosion inhibiting chemicals used and their effectiveness on the materials;

- Ratio of chemicals in the formulation;

- Amount of VCI on the paper or in the film;

- pH of the finished product;

- Water solubility and effectiveness of the corrosion inhibitor in the presence of moisture and high humidity; and

- Overall packaging design and conditions expected during packing, shipping and storing.

Deciding on the right VCI protection also demands consideration of the length of protection required, climate conditions for storage and transport, size and weight of parts, chemicals or residues on the parts, current processing and cleaning methods, and proximity of packaging-station location to other processes.

A supplier to metalformers looking for VCI protection also will discover whether parts will be shipped domestically or internationally.

“Obviously, international shipping demands increased protection because the parts will be exposed to more severe elements over a longer period of time,” says Simpson, noting that a number of paper and plastic-film packaging solutions are available to fit a metalformer’s current packaging process and can be introduced easily into its operations. MF

View Glossary of Metalforming Terms

See also: Daubert Cromwell

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

FinishingInline Addition of Corrosion Inhibitor for Galvanized Welded...

Tuesday, July 9, 2024

Finishing

FinishingDayton Rogers Adds Powder Coating Division

Wednesday, June 19, 2024