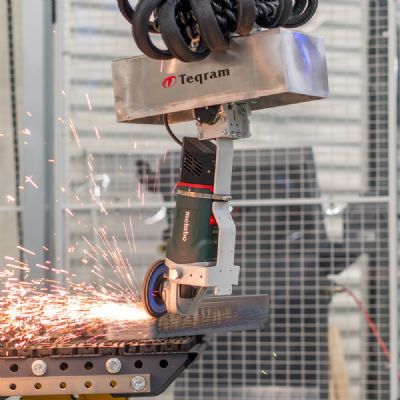

Cutting, Grinding and Combination Abrasive Wheels

June 9, 2023Comments

Weiler Abrasives

Booth B33027

Designed for demanding metal fabrication applications using portable angle grinders, Tiger 2.0 zirconia alumina and aluminum oxide cutting, grinding and combo wheels from Weiler Abrasives last to 40-percent longer than standard wheels to increase efficiency when cutting and grinding. The wheels feature a blotter design that includes a patent-pending Optimum Use Line, a visual indicator that helps the operator use the wheel to its full life. This innovation reduces changeovers, allowing for greater productivity while also reducing waste and abrasive spend. In some cases, users experience three times more efficiency as compared to their previous abrasives, according to company officials.Tiger 2.0 grinding wheels feature anti-chipping technology, an advanced bond formulation that reduces uneven edge wear and chipping to improve safety and user experience while extending wheel life. And, the addition of a QR code on the wheels makes it convenient for operators to access crucial safety information where and when they need it. Taking labor shortages into consideration, the wheels produce consistent results among different users to reduce training time and minimize rework, and make cutting and grinding easier to lessen operator fatigue and improve employee retention.

Tiger 2.0 wheels are available in Type 1, Type 27 and Type 28 options, and in sizes from 4 to 9 in.. They are intended for use on portable angle grinders.

See also: Weiler Corporation

Technologies: Finishing