seen at fabtech

Long-Lasting Nonwoven Flap Discs Deliver Quick Cutting, Fine Finishes

December 9, 2022Comments

At FABTECH…Norton | Saint-Gobain Abrasives introduced Norton Vortex Rapid Prep nonwoven flap discs that last longer and produce significantly increased cutting rates and smear-free finishes, according to company officials. Vortex agglomerated aluminum-oxide-grain technology reportedly enables the cutting power of a coarser grit while producing a finer finish in one abrasives-disc product. The company reports that based on tests performed, the nonwoven discs can increase material removal rates by more than 50 percent as compared to nonwoven medium-grit flap discs.

At FABTECH…Norton | Saint-Gobain Abrasives introduced Norton Vortex Rapid Prep nonwoven flap discs that last longer and produce significantly increased cutting rates and smear-free finishes, according to company officials. Vortex agglomerated aluminum-oxide-grain technology reportedly enables the cutting power of a coarser grit while producing a finer finish in one abrasives-disc product. The company reports that based on tests performed, the nonwoven discs can increase material removal rates by more than 50 percent as compared to nonwoven medium-grit flap discs.

Ideal for light blending, stripping, edge breaking and surface-prep applications in metal fabrication and welding, the flap discs feature special 3D nonwoven abrasive layers. This design ensures uniform finishing with a consistently low surface-finish value. In addition, multiple layers of surface-conditioning material provide added life, fewer disc changes for better efficiency and reduced vibration. The discs also feature Norton’s Clean Bond resin technology for smear-free finishes, even on high-nickel-content alloys, and reduced loading when cutting aluminum and other softer metals. They also provide forgiveness and reduced vibration on uneven surfaces. The discs are offered in fine, very fine, medium and coarse grits.

See also: Saint Gobain Abrasives

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Finishing

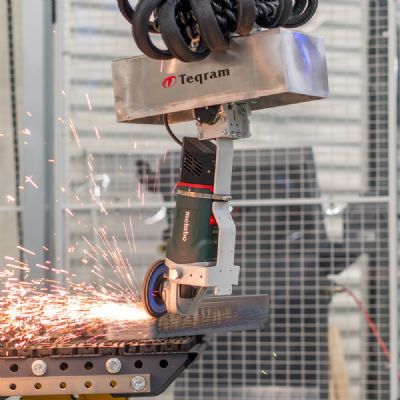

FinishingVia 3D Vision, Robotic Grinding Without Programming

Monday, March 3, 2025

Finishing

FinishingArku Sets Up Shop in South Carolina

Tuesday, September 17, 2024

Finishing

FinishingUpgraded High-Performance Cutting, Grinding and Combination ...

Wednesday, August 28, 2024