Peening Promises Polished Tools Quickly, with Optimum Properties

March 1, 2017Comments

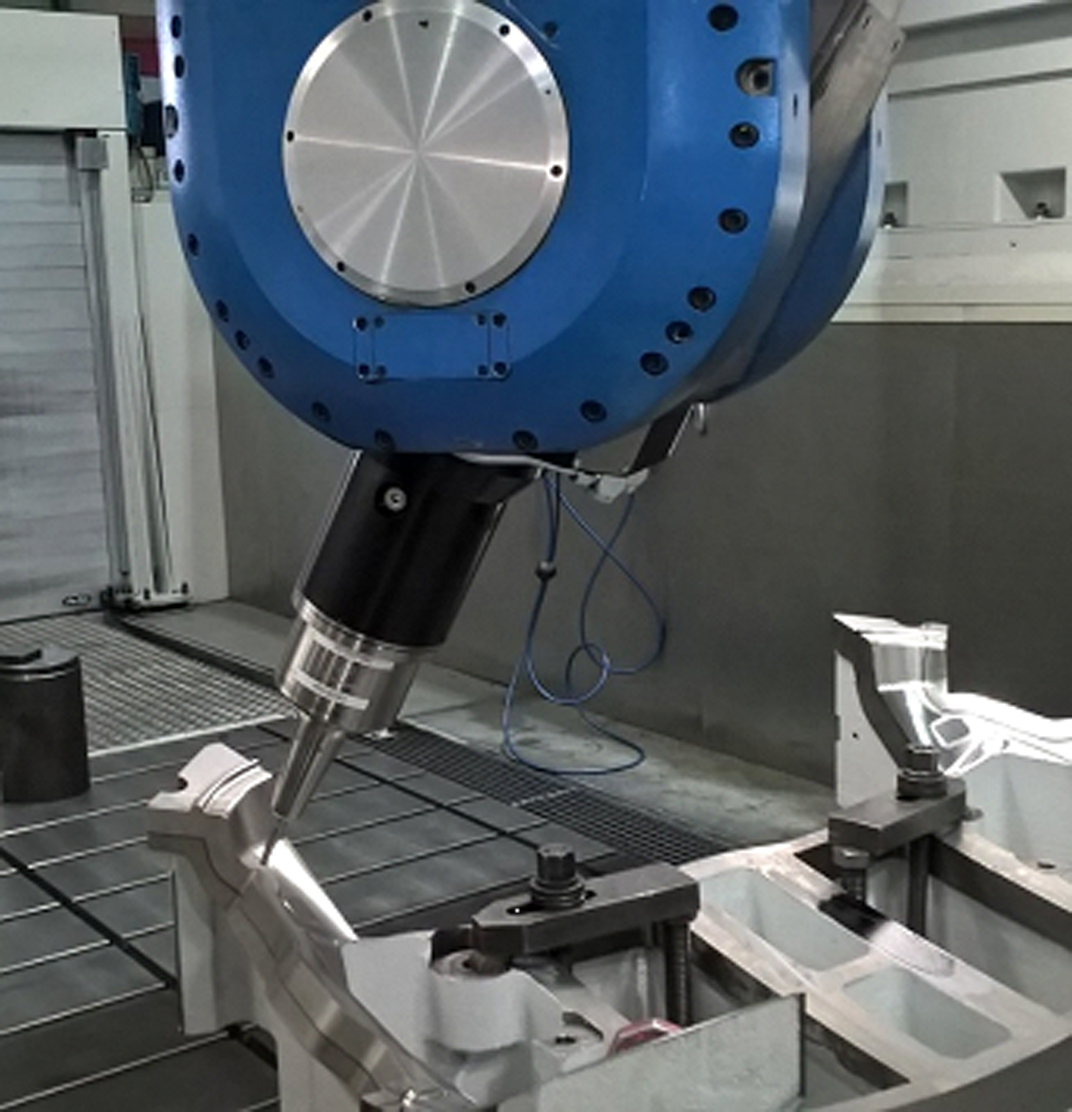

German-based company accurapuls (with North American offices in Edmonton, Alberta, Canada) has developed the micro-cold-forging (MCF) process for improving the surface finish of dies and molds. Aimed at the automotive industry, the technology is said to replace manual hand polishing of tools, by using an automated peening hammer to improve surface finish. The hammer can make as many as 300 hits/sec. and impart forces to 180 kg/hit.

German-based company accurapuls (with North American offices in Edmonton, Alberta, Canada) has developed the micro-cold-forging (MCF) process for improving the surface finish of dies and molds. Aimed at the automotive industry, the technology is said to replace manual hand polishing of tools, by using an automated peening hammer to improve surface finish. The hammer can make as many as 300 hits/sec. and impart forces to 180 kg/hit.

In testing performed by automakers, hammer-peened tooling (deep-draw tools for structural and outer-skin stampings, as well as bending/post-forming tools) using the MCF process exhibits not only finely polished surfaces but also improved surface hardness and increased wear resistance. Die-tryout time reportedly has been reduced, with a significant reduction in tooling cost.

accurapuls: www.accurapuls.ca

Technologies: Finishing

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingAndritz to Acquire Salico Group

Wednesday, July 2, 2025

Finishing

FinishingNew Exair Mobile App Provides Enhanced User Experience

Monday, August 26, 2024

Finishing

FinishingWhy Automated Deburring Works in Fabrication

Lou Kren Thursday, March 30, 2023