Quick, Efficient Slag Removal

November 11, 2024Comments

Steel service center SteelMart recently sought a solution for improving the efficiency of its plate-cleaning processes—highly labor-intensive and inefficient. With eight CNC cutting tables inhouse, the firm’s team typically would spend 1 hr. cleaning slag from plate for every 3 hr. of production. Manual cleaning involved chisels, hammers and handheld de-slagging machines.

Steel service center SteelMart recently sought a solution for improving the efficiency of its plate-cleaning processes—highly labor-intensive and inefficient. With eight CNC cutting tables inhouse, the firm’s team typically would spend 1 hr. cleaning slag from plate for every 3 hr. of production. Manual cleaning involved chisels, hammers and handheld de-slagging machines.

"Our outdated methods couldn't keep up with demand," says Nick Alspach, vice president of operations. "Manual plate cleaning required eight people working full shifts—not the type of jobs we want to offer. We needed a safer, cleaner and more efficient solution."

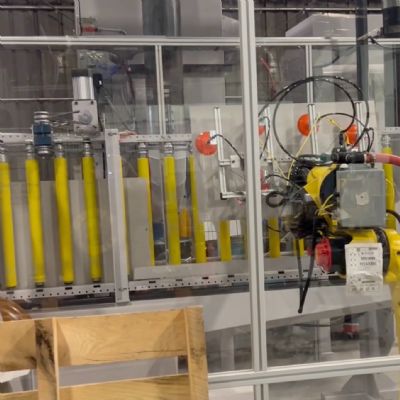

Determined to find a better solution, SteelMart’s management team turned to Lissmac and its model SMB-M 1500-D2 grinding and deburring machine, designed for the mechanical removal of slag on both sides of plate material. Installation of the machine marked a turning point for SteelMart, yielding cleaner parts and immediately easing downstream processes. The ergonomic design of the machine also addressed concerns about worker health, reducing the risk of carpal tunnel syndrome and improving overall air quality by capturing slag in larger chunks and incorporating magnetic collection.

"The difference has been night and day," notes Alspach. "We went from struggling to keep up with manual cleaning to having a machine that not only increased productivity but also made the workplace safer."