Vertical Blast System Tackles High-Volume Sheet Metal Surface Prep

November 11, 2024Comments

Guyson USA, Saratoga Springs, NY, a manufacturer of

automated surface-preparation equipment, has introduced the model TR-1000

custom vertical blast system. Fully automated, the machine proves ideal for use

in the aerospace, automotive and other industries that require meticulous

surface preparation for metal sheets.

Guyson USA, Saratoga Springs, NY, a manufacturer of

automated surface-preparation equipment, has introduced the model TR-1000

custom vertical blast system. Fully automated, the machine proves ideal for use

in the aerospace, automotive and other industries that require meticulous

surface preparation for metal sheets.

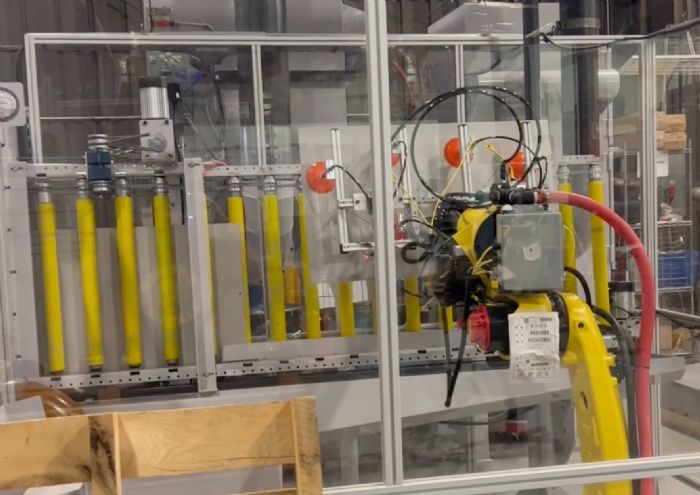

Engineered for manufacturers and fabricators engaged in cutting, bending and coating sheet metal, the TR-1000 features:

- Dual-sided blasting: Equipped with 18 oscillating blast guns, the unit blasts both sides of metal sheets simultaneously, reducing cycle time and minimizing warping.

Rapid robotic loading/unloading: With automated loading and unloading via a robotic arm, handling time is minimized, quickening production cycles. - Pre- and post-blast cleaning: Sheets are first cleaned with compressed air to ensure optimal blasting conditions, and then undergo a second cleaning stage to remove any residual media before re-stacking.

- Enhanced throughput: Capable of processing to 300 linear ft./hr., the TR-1000 can manage approximately 45 part/hr.

- Pneumatic sheet separation: Ensures smooth, uninterrupted operation with the robotic loading system.

See also: Guyson Corporation of U.S.A.

Technologies: Finishing