The PMA ICOSPA Delegation Included:

David Klotz, PMA presidentTroy Turnbull, immediate past chair (president/CEO,

Industrial Innovations, Inc.)Doug Johnson, 2022 chair (president, Marion Manufacturing)Jeff Aznavorian, 2022 vice chair (president, Clips &

Clamps Industries)Dave Arndt, PMA ICOSPA delegate (president emeritus,

Pentaflex, Inc.)Brian Murphy, vice president, Eagle MetalsPatrick O’Callaghan, sales and marketing manager, Zierick ManufacturingEdward Morris, president, P/A IndustriesTom Busse, president, Rockford Toolcraft, Inc.Peter Bodi, president, Accurate Machine and Tool Ltd. Michael Vohland, PMA publisher and vice president of sales Brad Kuvin, editorial director, MetalForming magazine

Plant Tours—Always a Hit

Before hearing from the conference’s speaker lineup, the 2022 ICOSPA Congress kicked off with two plant tours of local metal forming companies. First stop: Gestamp Tallent UK, part of the Global Gestamp Automacion Corp., headquartered in Madrid, Spain, and one of the largest metal forming companies in the world, with 115 factories and 13 R&D centers. Gestamp works with nearly every automotive OEM, from its numerous product divisions:

- Chassis (steel and aluminum), integrating extrusions,

castings, hydroformed and machined components

- Closures, including door hinges and sunroof mechanisms

- Body-in-white (BIW)—cold and high-strength hot stampings and assemblies

- Electrification—design and manufacture of battery trays.

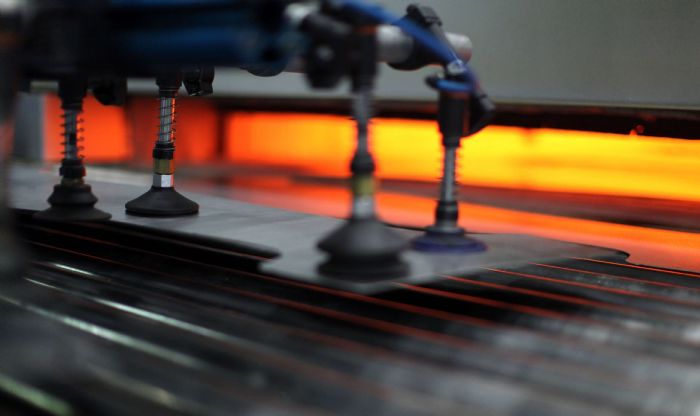

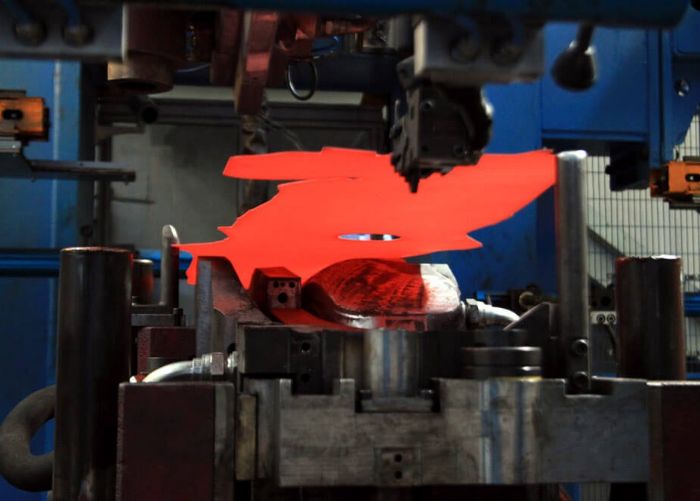

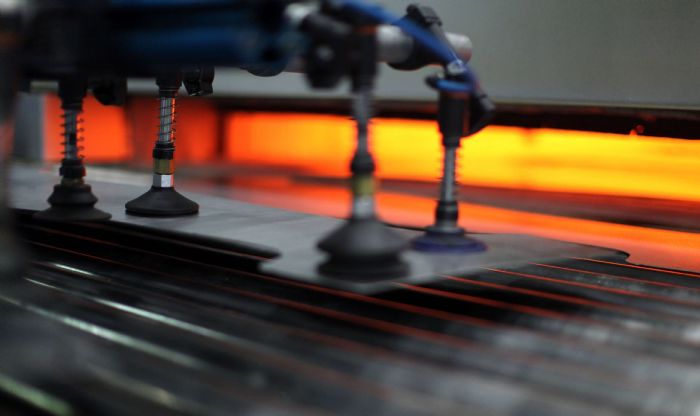

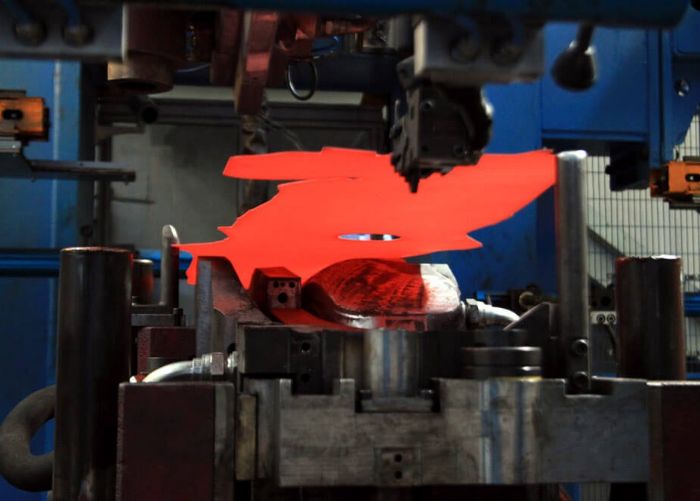

We toured the firm’s 50,000-sq.-m plant in Cannock, 20 miles north of Birmingham, which opened in 2018 and focuses on BIW and electrification applications. Dominating the floorplan here are two prolific hot stamping lines, each equipped with a pair of Loire hydraulic presses fed by blank-handling robots and a walking-beam conveyor to move parts along 16 temperature-controlled heating zones. Also on the floor: an Arisa 2500-ton servo press with a 2.5 by 6.1-m bed, and we spied several Trumpf TruLaser Cell 8030 multi-axis laser-cutting

We toured the firm’s 50,000-sq.-m plant in Cannock, 20 miles north of Birmingham, which opened in 2018 and focuses on BIW and electrification applications. Dominating the floorplan here are two prolific hot stamping lines, each equipped with a pair of Loire hydraulic presses fed by blank-handling robots and a walking-beam conveyor to move parts along 16 temperature-controlled heating zones. Also on the floor: an Arisa 2500-ton servo press with a 2.5 by 6.1-m bed, and we spied several Trumpf TruLaser Cell 8030 multi-axis laser-cutting  machines used to trim hot-stamped BIW parts. We also toured the plant’s production area for fabricating aluminum battery trays, launched in late 2021 and highlighted by friction-stir welding of extrusions, as well as CNC machining, gas-metal-arc welding and clinching operations.

machines used to trim hot-stamped BIW parts. We also toured the plant’s production area for fabricating aluminum battery trays, launched in late 2021 and highlighted by friction-stir welding of extrusions, as well as CNC machining, gas-metal-arc welding and clinching operations.

Next stop: Birmingham’s Brandauer & Co. Ltd., one of Europe’s largest and oldest (founded in 1862) precision stamping companies. Among the products manufactured here: electrical-steel laminations, EloPin press-fit pins and cable clips. The sixth-generation family-owned company, as we learned from CEO Rowan Crozier, recently has focused on expanding its toolroom operations, including the development of three levels of tooling offerings to customers, the highest level being what Crozier terms “modular tooling.” Crozier also explained the firm’s launch of a second facility—devoted strictly to developing new tools—as well as its new Precision Tooling Academy, providing advanced training for new toolmakers.

Touring the plant, we spied several high-speed presses,

mostly Bruderer models, and the newest press to hit the floor: a Yamada NXT

80-ton press equipped with a double link-motion mechanism. As explained by our

tour guide, this allows for slide-motion deceleration near bottom dead center,

which minimizes vibration inside the die during cutting and forming operations.

Touring the plant, we spied several high-speed presses,

mostly Bruderer models, and the newest press to hit the floor: a Yamada NXT

80-ton press equipped with a double link-motion mechanism. As explained by our

tour guide, this allows for slide-motion deceleration near bottom dead center,

which minimizes vibration inside the die during cutting and forming operations.

Enlightening Conference Presentations

Not to be outdone by the plant tours, ICOSPA Congress attendees enjoyed an all-star lineup of conference presenters. On the agenda:

Francisco Riberas, executive chairman of Gestamp Automocion,

who discussed major challenges and opportunities in the automotive sector. This includes, as we learned on the Gestamp

plant tour, a focus on hot stamping. Riberas noted that the company is

developing a high-speed hot stamping process that will operate at the same

speed as cold stamping, and that eliminates the laser cutting operation.

Francisco Riberas, executive chairman of Gestamp Automocion,

who discussed major challenges and opportunities in the automotive sector. This includes, as we learned on the Gestamp

plant tour, a focus on hot stamping. Riberas noted that the company is

developing a high-speed hot stamping process that will operate at the same

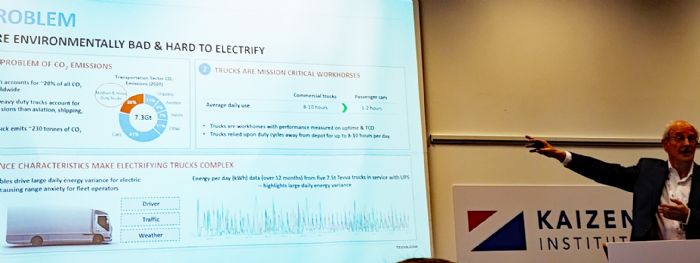

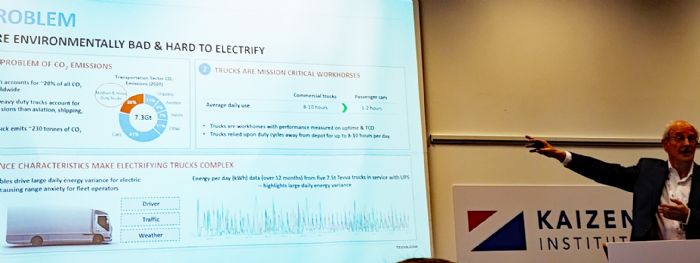

speed as cold stamping, and that eliminates the laser cutting operation. Ian Harnett, chairman of Tevva Electrical Trucks, provided a presentation titled, “Moving the world towards a better way of transporting everything for everybody.” Tevva, a new electric-truck manufacturer based in Tilbury, England, has developed a battery electric vehicle (BEV) as well as a BEV with a hydrogen-fuel-cell range extender.

Ian Harnett, chairman of Tevva Electrical Trucks, provided a presentation titled, “Moving the world towards a better way of transporting everything for everybody.” Tevva, a new electric-truck manufacturer based in Tilbury, England, has developed a battery electric vehicle (BEV) as well as a BEV with a hydrogen-fuel-cell range extender. - Dan Hurd, strategy & transactions partner of EY-Parthenon, who discussed global supply-chain issues for the future. He spoke at length of the impact of Brexit on the U.K. manufacturing economy, the risks of supplier failure around the world and the trend toward “just in case” vs. “just in time,” as a way to increase supply-chain resilience.

- Jianguo Lin, research and business development manager at Imperial College London (and founder of Impression Technologies), who shared his perspectives on future challenges on forming technologies for vehicle lightweighting. Specifically, Lin described efforts to develop Impression Technologies’ HFQ (hot form quench) high-speed forming process for developing complex deep-drawn aluminum components used in EVs and other lightweight structures.

- Antonio Costa, CEO of the Kaizen Institute, based in Bahnhofplatz,

Switzerland, who discussed Industry 4.0 innovation and strategies for building

a digital-transformation strategy.

- Gianfranco Ruggiero, senior product manager of AutoForm, who wrapped up the proceedings with a presentation titled, “Smart Production begins with Smart Process Engineering.”

The next ICOSPA Congress takes place in 2025 in Osaka, Japan. And then, in 2028, the event moves to the

United States, under the direction of PMA.

Stay tuned to the PMA website, www.pma.org, for details as they emerge! MF

See also: Precision Metalforming Association

Technologies: Management

We toured the firm’s 50,000-sq.-m plant in Cannock, 20 miles north of Birmingham, which opened in 2018 and focuses on BIW and electrification applications. Dominating the floorplan here are two prolific hot stamping lines, each equipped with a pair of Loire hydraulic presses fed by blank-handling robots and a walking-beam conveyor to move parts along 16 temperature-controlled heating zones. Also on the floor: an Arisa 2500-ton servo press with a 2.5 by 6.1-m bed, and we spied several Trumpf TruLaser Cell 8030 multi-axis laser-cutting

We toured the firm’s 50,000-sq.-m plant in Cannock, 20 miles north of Birmingham, which opened in 2018 and focuses on BIW and electrification applications. Dominating the floorplan here are two prolific hot stamping lines, each equipped with a pair of Loire hydraulic presses fed by blank-handling robots and a walking-beam conveyor to move parts along 16 temperature-controlled heating zones. Also on the floor: an Arisa 2500-ton servo press with a 2.5 by 6.1-m bed, and we spied several Trumpf TruLaser Cell 8030 multi-axis laser-cutting  machines used to trim hot-stamped BIW parts. We also toured the plant’s production area for fabricating aluminum battery trays, launched in late 2021 and highlighted by friction-stir welding of extrusions, as well as CNC machining, gas-metal-arc welding and clinching operations.

machines used to trim hot-stamped BIW parts. We also toured the plant’s production area for fabricating aluminum battery trays, launched in late 2021 and highlighted by friction-stir welding of extrusions, as well as CNC machining, gas-metal-arc welding and clinching operations. Touring the plant, we spied several high-speed presses,

mostly Bruderer models, and the newest press to hit the floor: a Yamada NXT

80-ton press equipped with a double link-motion mechanism. As explained by our

tour guide, this allows for slide-motion deceleration near bottom dead center,

which minimizes vibration inside the die during cutting and forming operations.

Touring the plant, we spied several high-speed presses,

mostly Bruderer models, and the newest press to hit the floor: a Yamada NXT

80-ton press equipped with a double link-motion mechanism. As explained by our

tour guide, this allows for slide-motion deceleration near bottom dead center,

which minimizes vibration inside the die during cutting and forming operations. Francisco Riberas, executive chairman of Gestamp Automocion,

who discussed major challenges and opportunities in the automotive sector. This includes, as we learned on the Gestamp

plant tour, a focus on hot stamping. Riberas noted that the company is

developing a high-speed hot stamping process that will operate at the same

speed as cold stamping, and that eliminates the laser cutting operation.

Francisco Riberas, executive chairman of Gestamp Automocion,

who discussed major challenges and opportunities in the automotive sector. This includes, as we learned on the Gestamp

plant tour, a focus on hot stamping. Riberas noted that the company is

developing a high-speed hot stamping process that will operate at the same

speed as cold stamping, and that eliminates the laser cutting operation. Ian Harnett, chairman of Tevva Electrical Trucks, provided a presentation titled, “Moving the world towards a better way of transporting everything for everybody.” Tevva, a new electric-truck manufacturer based in Tilbury, England, has developed a battery electric vehicle (BEV) as well as a BEV with a hydrogen-fuel-cell range extender.

Ian Harnett, chairman of Tevva Electrical Trucks, provided a presentation titled, “Moving the world towards a better way of transporting everything for everybody.” Tevva, a new electric-truck manufacturer based in Tilbury, England, has developed a battery electric vehicle (BEV) as well as a BEV with a hydrogen-fuel-cell range extender.