Shell Leveraging AM for Spare Parts

August 2, 2021Comments

Believing that additive manufacturing (AM) can reduce spare-parts costs, delivery time and carbon footprint, Shell reveals in a new article on its website that it is collaborating with AM providers to “push the innovation of 3D printing for the energy sector.”

Believing that additive manufacturing (AM) can reduce spare-parts costs, delivery time and carbon footprint, Shell reveals in a new article on its website that it is collaborating with AM providers to “push the innovation of 3D printing for the energy sector.”

Shell began 3D printing inhouse in 2011, using a metal laser-printing machine to produce testing equipment for laboratory experiments at the Shell Technology Centre Amsterdam (Netherlands). Currently, the company employs about 15 metal, polymer and ceramic printers, located at its technology centers in Amsterdam and Bangalore, India.

Focusing on 3D printing for spare parts, novel designs and visualization objects, Shell, according to company officials, can manufacture spare parts itself, but looks to source that work. Its position on the sourcing of 3D-printed components:

- “Collaborate with an original equipment manufacturer (OEM) qualified to supply 3D-printed components

- When an OEM is not available, and in compliance with intellectual property (IP) laws, Shell can reverse-engineer the part and have a commercial supplier print it from a 3D model

- In emergency cases and when IP is not an issue, Shell will print spare parts inhouse.”

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

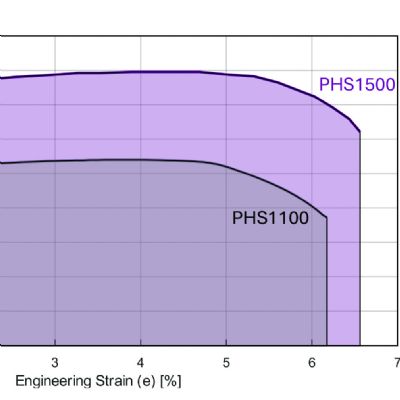

MaterialsLocal and Global Formability—Part 2: Effects on Material Sel...

Eren Billur April 29, 2024

Welding and Joining

Welding and JoiningMiller Electric Introduces OptX 2-kW Handheld Fiber Laser We...

Wednesday, May 1, 2024

Management

ManagementWipfli Acquires Harbour Results, Inc.

Wednesday, May 1, 2024