Tool Coatings Keep Truck-Part Maker in the Fast Lane

August 1, 2011Comments

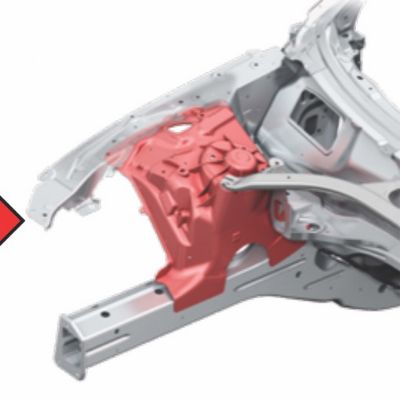

At its 125,000-sq.-ft. plant in Springfield, OH, Pentaflex stamps and assembles components primarily for the tractor-trailer industry. New federal regulations governing braking distance and emissions have brought new work to Pentaflex as trucking companies look to upgrade their fleets. Large tooling details used to produce new parts require coatings to prevent premature wear and breakage, and ensure high-quality product.

Pentaflex produces transmission, brake and emission-control parts for tractor trailers, of stainless- and HSLA-steel grades.

Even with higher fuel costs, the trucking industry has been bringing new business to Pentaflex. Regulations targeting stopping distances for over-the-road trucks go into full effect at the end of 2011, and truck manufacturers have created new parts to do the job. These new parts and assemblies have found their to Pentaflex as high-volume part contracts. The same is true for components related to truck emissions. As a result, Pentaflex and its nearly 100 employees have been running two shifts, with a third in the offing. The company primarily stamps parts from stainless-steel and high-strength low-alloy (HSLA) material in hydraulic and mechanical presses in capacities as large as 2300 tons.

Recently, Pentaflex engineers have had to not only select a tool coating to withstand the punishment of tough, high-volume forming, but they also had to identify a coater with the capacity to handle its large details.

Deep-Draw Details

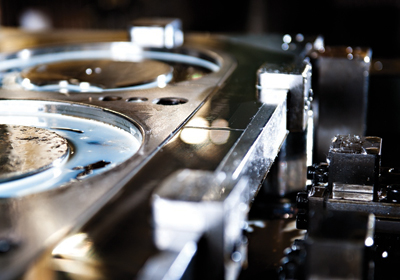

Prior experience in selecting a tool coating guided Pentaflex in selecting the best coating method for a new project, as the company has had good success using a physical-vapor-deposition (PVD) process (FortiPhy, from Phygen Coatings, Inc., Minneapolis, MN). The goal this time: Protect large tooling details in production of deep-drawn parts for tractor-trailer air-regulatory units, which comprise a portion of the new work arising from emission regulations.

“These deep-drawn stainless-steel parts are very large, with draws from 8 to 10 in.,” explains Michael Stull, Pentaflex tooling manager.

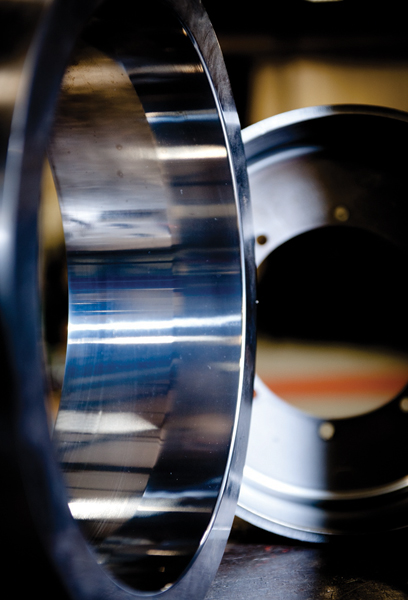

The firm employs two hydraulic presses, 2300- and 1600-ton models, to draw the parts, mostly via hand transfer. Tooling details used to produce these large parts are very large, some stretching to 36 in. long. Coating such large parts occurs at a recently installed PVD chamber at Phygen, a chamber that tripled its previous capacity.

“This means that we can deliver the same coating quality with practically no size limitation for draw rings, draw pads and form dies,” says Phygen president David Bell. “Also, tooling that before would have to be made and coated in smaller segments now can be made in larger pieces, eliminating tooling lines in parts and the risk of tool distortion or size change that might occur using higher-temperature coating processes.”

Ideal Tool Protection

The selection of Phygen for the deep-draw details resulted from a previous tool-coating quest.

“About seven years ago we started looking for coatings for tooling used to stamp large brake drums from 1025 and 1026 high-strength low-alloy steel,” recalls Stull. “We experienced excessive galling that only allowed us to produce 900 parts before having to repolish and clean the details. We tried all types of coatings without any improvement.”

Searching for an answer, Pentaflex shipped precision die sleeves—large details with tolerances maintained at ±0.0005 in.—to Phygen. The tool coater applied its FortiPhy process—which creates a thin and dense nanocrystalline coating structure that adheres to virtually any tool-steel substrate—to the rings. The coating process creates highly energetic nanoparticles, reportedly resulting in a higher level of adhesion—three times higher—than is possible with conventional coating processes. The coating also boasts a low coefficient of friction, less than 0.1 in typical lubricated conditions.

A previously tested coating, which only brought an uninterrupted tool life of 900 hits, would fail owing to an adhesion process that would pull out carbon from the tools, according to Stull. The FortiPhy coating, on the other hand, uses a process that doesn’t deplete the tools’ carbon grains.

In addition, the coating process offered another feature that caught Stull’s attention. While chemical-vapor-deposition and thermal-diffusion coatings typically are applied at temperatures exceeding 1800 F, FortiPhy requires significantly lower temperatures. This lessens the chance of distortion that can play havoc with tolerances, and minimizes tool-hardness concerns.

“After employing the FortiPhy process, we went from polishing details after 900 hits to surpassing 40,000 hits before required maintenance,” says Stull. “In the past seven years we’ve coated a number of tools with this process, mostly of DC53 material and some D2. For the large drums, we use A2 due to the high ironing pressures during forming—requiring a minor amount of expansion within the tools to prevent them from fracturing. The coating process and heattreating does lower the Rockwell hardness a bit, but doesn’t distort the tools. We send them out at Rc 60-62, and after coating they come back at Rc 58-59, well within their working range.”

Coating a Surer Bet Close to Home

With a toolroom roster of 11 employees across two shifts, focusing mostly on tool maintenance and repair with a bit of build, Pentaflex appreciates tooling that lasts over the long haul. Finding coatings that keep tools producing help the company service its growing tractor-trailer customer base. A few years back, Pentaflex made business decisions that revealed how critical the correct coating can be to maintaining top-notch production.

“At one time we had details produced overseas to reduce costs,” recalls Stull. “Those suppliers could only recommend thermoreactive-diffusion coatings for these details. But these coatings failed to hold up given the type of work we perform and the types of tool steels we use. So we purchased the details coating-free and shipped them to Phygen for the correct coating. Now we source all of our tooling domestically, and combining that with ideal coating performance, we produce parts that meet our customers’ needs.” MF

Article provided by Phygen Coatings, Inc.: 888/749-4361; www.phygen.com.View Glossary of Metalforming Terms

See also: PHYGEN

Technologies: Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsGiga Stamping to Compete with Giga Casting

Eren Billur Tuesday, June 10, 2025

Materials

MaterialsNovelis Tests Industrial-Scale Use of Hydrogen in Aluminum-R...

Friday, February 28, 2025

Materials

MaterialsMetal Supermarkets in Ottawa, Canada, Under New Ownership

Friday, November 15, 2024