Heat-Assisted Adiabatic Cutting of High-Strength Steel

October 23, 2020Comments

In the last two Cutting Edge columns, I explained how heating can improve the formability of boron-alloyed steels and some aluminum alloys. In both cases, we heat the sheet metal in a furnace to their optimum forming temperature. Here we’ll discuss a heat-assisted cutting technology where the sheet metal blank itself generates the heat required for cutting, without the need for a furnace or other heating device.

How Does a Blank Heat Itself?

Most metal formers should have experienced that a part exiting the press may be quite hot. This occurs because the sheet metal generates heat as it deforms. The temperature of the part may depend on several factors, including the amount of work done (press force and working stroke length), and how quickly the part is produced (directly proportional to stroke).

Most metal formers should have experienced that a part exiting the press may be quite hot. This occurs because the sheet metal generates heat as it deforms. The temperature of the part may depend on several factors, including the amount of work done (press force and working stroke length), and how quickly the part is produced (directly proportional to stroke).

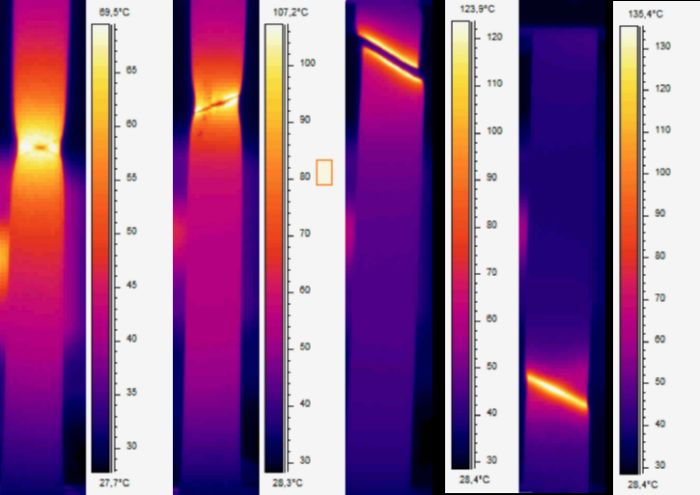

Fig. 1 illustrates tensile-test results, recorded with a thermal camera, for two different steel grades—DC04 (a mild steel similar to a deep drawing grade), and HCT980X (similar to DP 1000). The high-speed thermal camera captured the temperature increase in the fracture zone.

When pulling the mild steel at 50 mm/sec., the temperature at the fracture zone peaks at 69.5 C. When quadrupling the test speed, heat cannot dissipate as quickly as during the first condition. Also, due to strain-rate effects, about 5 percent more work is performed, and the temperature rises to 107.2 C. Note: After only 0.5 sec., the maximum temperature drops to 94.0 C. The heating and cooling cycle occurs in very short time intervals and is localized in a very confined area of deformation.

When we pull the higher-strength HCT980X alloy, the peak temperatures are 123.9 C and 135.4 C, respectively.

How is This an Advantage?

Heating the blank typically is a disadvantage for metal formers. An automotive-OEM engineer once told me that if the draw-tool temperature of a door-inner panel increases by 7 C, the binder tonnage must be reduced to avoid cracks. The heating effect also limits the maximum parts produced per minute, since press speed must be reduced in order to control the tool temperature.

Heating the blank typically is a disadvantage for metal formers. An automotive-OEM engineer once told me that if the draw-tool temperature of a door-inner panel increases by 7 C, the binder tonnage must be reduced to avoid cracks. The heating effect also limits the maximum parts produced per minute, since press speed must be reduced in order to control the tool temperature.

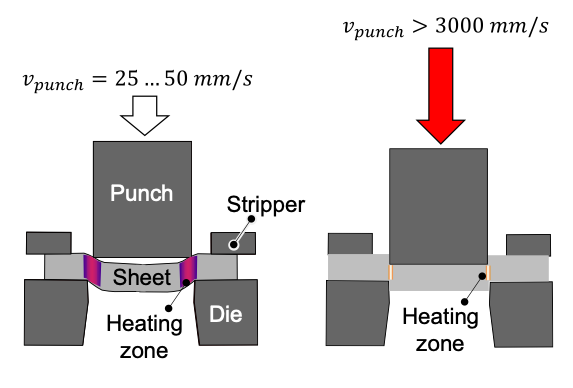

During blanking, the plastic deformation—and so the heating—is very localized to just the periphery of the punch (Fig. 2a).

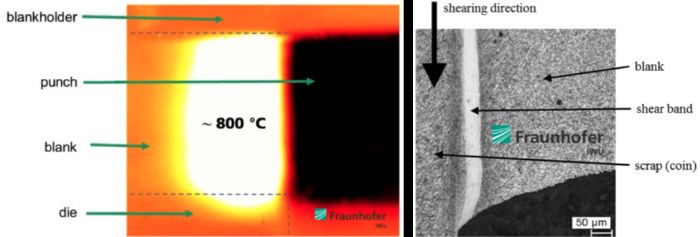

If punch speed exceeds 3 m/sec., then the time required to cut the sheet decreases to a few milliseconds (Fig. 2b). There would be no time to dissipate the heat in the shear zone, thus the name adiabatic. This would generate a very narrow adiabatic shear band (10 to 50 μmm) and reach 700 C (Fig. 3).

If punch speed exceeds 3 m/sec., then the time required to cut the sheet decreases to a few milliseconds (Fig. 2b). There would be no time to dissipate the heat in the shear zone, thus the name adiabatic. This would generate a very narrow adiabatic shear band (10 to 50 μmm) and reach 700 C (Fig. 3).