Steel’s Boundless Value Proposition

March 29, 2024Comments

Annually, MetalForming celebrates the steel industry, recognizing the value that steelmakers deliver to metal formers. There’s no slowing down when it comes to introducing new, stronger alloys, easier to form and weld than ever before, enabling steel-consuming industries—automotive and other—to continue their own innovations.

To learn some of what’s new in steel, senior editor Kate Bachman reports in this issue on her talks with three steelmakers. From Nucor’s Dean Kanelos, market development and product applications manager: “New advanced high-strength-steel grades require significantly more rolling force. In turn, this requires the use of more powerful rolling mills to efficiently roll these steels to gauge… Several new grades require upgraded galvanizing lines with improved heat treat capabilities.”

Bala Krishnan, director, global R&D at ArcelorMittal, shares: “Modern steel-grade innovations have prioritized on manufacturability as much as delivered weight savings at the best value possible. This represents a huge shift from previous generations that prioritized lightweighting exclusively, leading to manufacturability challenges.”

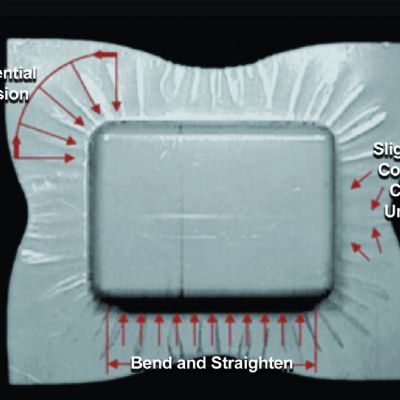

And, J.B. Chronister, senior director, business development at Cleveland Cliffs, notes: “Metal formers can manage residual springback and work hardening through different die configurations, edge strain limitations and laser blanking. Springback control is manageable in almost all cases with improved die-face compensation and die modeling.”

Next, we turn to the “politics of steel” and the industry’s commitment to environmental sustainability. Here we share just one example of many, in our news item describing Gestamp’s partnership with steel producers to develop the “net-zero car.” Late last year, Gestamp signed agreements with steelmakers SSAB and Tata Steel UK to increase the amount of fossil-free steel used in body-in-white and chassis-system products. Circularity is a key pillar for the decarbonization of the industry across the entire supply chain. The agreements come on the heels of Gestamp’s “circularity” agreement signed with ArcelorMittal in June 2023.

Per Gestamp, SSAB plans to deliver fossil-free steel to the market at a commercial scale in 2026, and to largely eliminate CO2 emissions from its own operations sometime near 2030. And, Gestamp’s agreement with Tata Steel UK aims to increase the percentage of recycled content associated with the steel provided to Gestamp from 17% to 30%.