Tackle Challenging Materials with Servo Presses

May 1, 2014Comments

Leverage the numerous advantages of servo-press technology to stamp high-strength steels and aluminum alloys.

Metal stampers face the challenges of forming advanced and varied materials while maintaining high levels of quality and throughput. At times it can be difficult to achieve both, especially when faced with challenging materials such as aluminum alloys and high-strength steels (HSS) that require slower forming speeds to achieve the desired quality, and a stable process. This contradiction of expectations can be resolved by using servo-direct press technology.

The advantages of programming a servo-driven press to form advanced materials can be compared to racing a bicycle through a curvy, hilly course. The rider gains speed down the hills, slows down to navigate the curves and then accelerates out of the curves to achieve maximum speed without losing control. This is how a servo press can accommodate the needs of the forming cycle when stamping advanced materials, by adapting to the requirements of the cycle. Just as a cyclist that races the entire course at the slow cornering speed will lose the race, so will a traditional mechanical press with an eccentric drive, forced to operate at the slowest forming speed throughout the entire cycle.

|

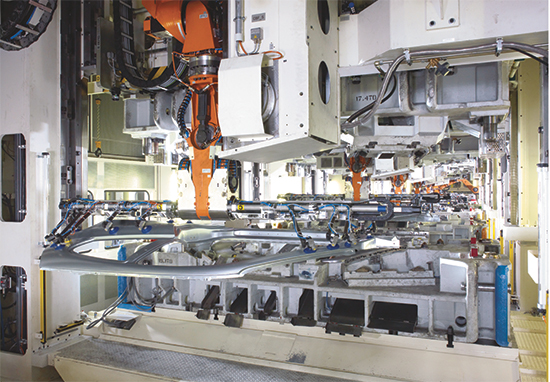

| Fig. 1—When stamping high-strength steels, the blankholder is larger in size and more solid in its design, which requires pressurization of additional gas springs, and may even require a slower velocity on the return stroke. Shown here are the blankholder station (drawing) and pad station (trim and form) for a bodyside outer. |

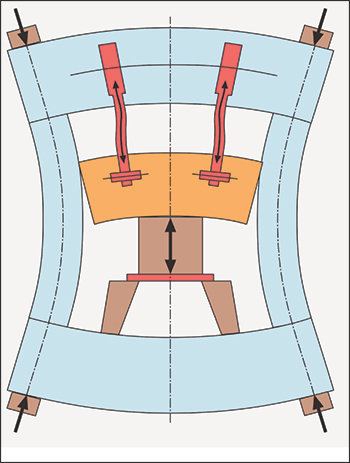

When forming special materials such as aluminum or HSS, several factors in the die influence the optimum forming speed. These include speed requirements of the blankholder as it opens or closes; special forming operations from cams within the die; and vibrations due to breakthrough as the material cuts. Programming the servo drive to accommodate these factors can greatly improve quality, die-component life and process stability while also delivering improved throughput.

Blankholders’ Impact on Slide Speed

When trimming materials such as aluminum or HSS, a blankholder inside the die fixes the part in place before the slide moves the die to begin the trimming operation. In the case of HSS, the blankholder must hold the part in place to ensure the blank does not move during the high-tonnage cutting operation. The stamper must take great care to control the process and ensure there is no excess energy emitted and that the process remains stable. Note: a similar reduction in speed is required when the slide touches the blankholder for drawing processes, as well.

Just before the slide engages the die, the blankholder accelerates to hold the part in position using gas springs (or pins). The blankholder engages and does not move while the slide moves down and then up to perform the trimming operation. When the slide returns, the springs or pins also must achieve a certain speed per tonnage to match the speed of the slide, to reduce vibration in the die and not overload cams or other in-die components. This is the velocity limit on the return stroke related to the blankholder. When stamping high-strength steels, the blankholder is larger in size and more solid in its design, which requires pressurization of additional gas springs or pins (Fig. 1), and may even require a slower velocity on the return stroke.

|

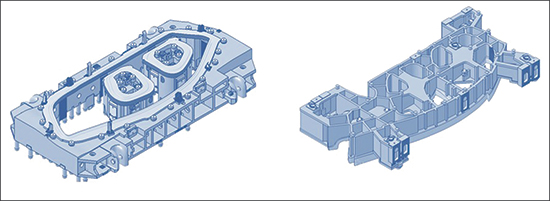

| Fig. 2—When looking at a cross section of cut HSS material, part of the cut that is a clean shear, followed by material breakthrough. When cutting high-strength steels, the high force required is stored energy within the press. |

Here, the benefit of servo drive is the ability to slow the slide speed to accommodate the blankholder, and then increase slide speed when the die is open. This optimizes throughput and process stability. To achieve a higher throughput, the maximum stroke rate of a servo press must be higher than that of a standard mechanical press.

A note for diemakers: Knowing that you can reduce the speed in the die may allow the use of less-complex or lighter die components, reducing costs without impacting throughput.

Cutting HSS, and its Impact on Slide Speed, Vibration (Wear) and Noise

When looking at a cross section of cut HSS material, part of the cut is a clean shear, followed by material breakthrough. When cutting high-strength steels, the high force required is stored energy within the press (Fig. 2). During the breakthrough portion of the cut, the energy releases into the press. This is comparable to pulling a string on a bow. As the string is pulled, energy stores in the bow. When released, vibration results. In a press, the breakthrough portion of the cut can result in strong vibrations, and the more energy stored the more vibration that occurs on release. The released vibrations within the press can stress the press components and diminish press accuracy and performance. Some of the resulting issues include:

• Loose components such as screws, scrap chutes, cabinets, piping and cables;

• Overloading anti-vibration elements;

• Early failure of sensitive components, such as a PC mounted on the uprights;

• Cracks on dies or welded seams in the press;

• Heavy shear wear resulting in reduced cutting-edge quality and shorter die-component life; and

• Higher noise levels.

Therefore, it is important to have a soft breakthrough of the material to release the energy from the press with minimal vibration. This is accomplished by using slower cutting and impact speeds. This will lead to reduced energy emission and less vibration in the process. In a press shop, this means less noise and reduced wear on die and press components.

For certain business situations, this noise reduction can be significant. In a study of a 450-ton monoblock servo press forming advanced materials, noise levels dropped by 40 percent compared to a traditional mechanical press. This allowed the stamper to meet neighborhood noise regulations and bring previously outsourced work back inhouse.

Again, like the bicycle race, this is an area that may define the speed and overall throughput of a mechanical press that would lose the race against a servo-driven press. With the ability to program a servo-driven press, slide acceleration can be lowered during cutting to keep vibration minimal. For example, we’ve seen applications using a traditional mechanical press where slide acceleration before BDC is 5g; it drops to less than 2g when using servo-drive programming. Vibration drops, reducing stress on press components and making the process more stable. The process can be stabilized even further by introducing a cushion, as the cushion box acceleration can match blankholder speed to further reduce vibration in the system. MFView Glossary of Metalforming Terms

See also: Andritz Schuler

Technologies: Materials, Stamping Presses