Laser Stirring Overview

Laser stirring has been adapted from electromagnetic arc stirring, a technique that combines the electromagnetic stirring of arc welds with electron-beam oscillation. This process has been shown to break up the dendritic microstructure of aluminum alloys, encourage an equiaxed grain structure, reduce thermal gradients at the edge of the melt pool and decrease mean grain size. Each of these attributes proves beneficial in reducing solidification cracking in high-strength aluminum alloys and austenitic stainless steels.

Laser stirring has been adapted from electromagnetic arc stirring, a technique that combines the electromagnetic stirring of arc welds with electron-beam oscillation. This process has been shown to break up the dendritic microstructure of aluminum alloys, encourage an equiaxed grain structure, reduce thermal gradients at the edge of the melt pool and decrease mean grain size. Each of these attributes proves beneficial in reducing solidification cracking in high-strength aluminum alloys and austenitic stainless steels.

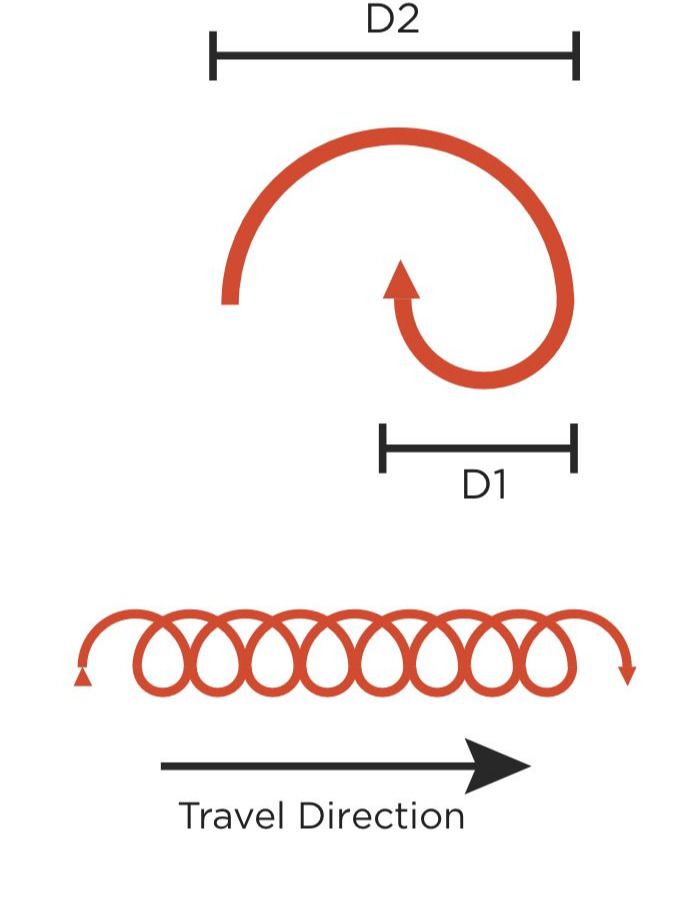

During LPBF, laser stirring replaces linear hatches with repeated circular or elliptical scan paths (Fig. 1). EWI’s laser-stirring process aims to:

- Produce a more equiaxed and isotropic as-printed LPBF microstructure

- Mitigate solidification and liquation cracking in crack-prone alloys.

Experimental Work

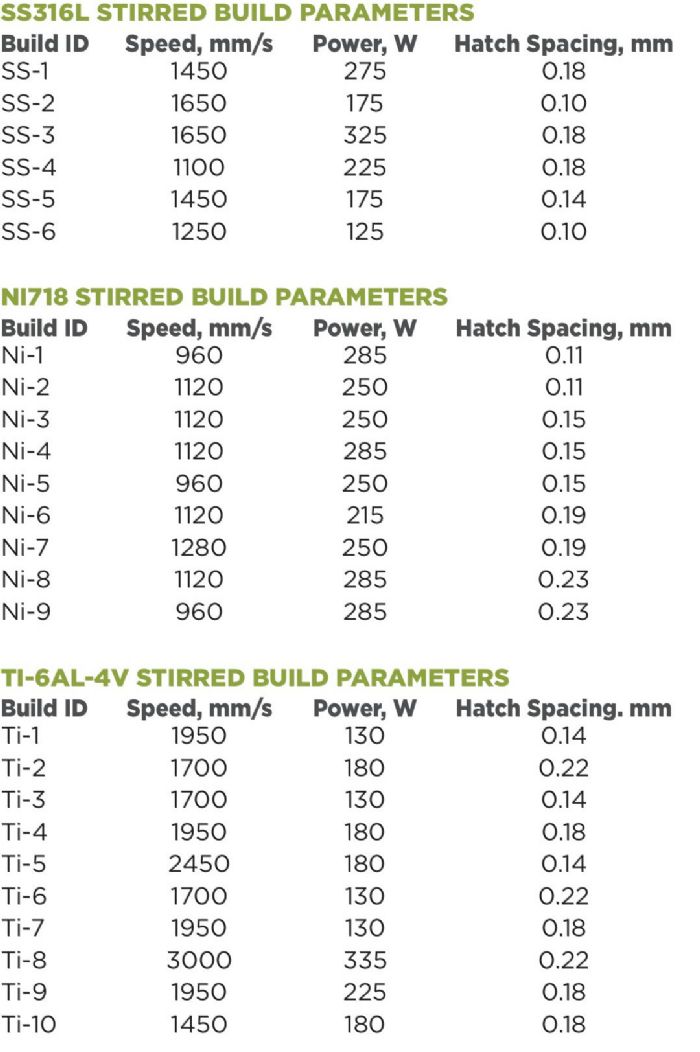

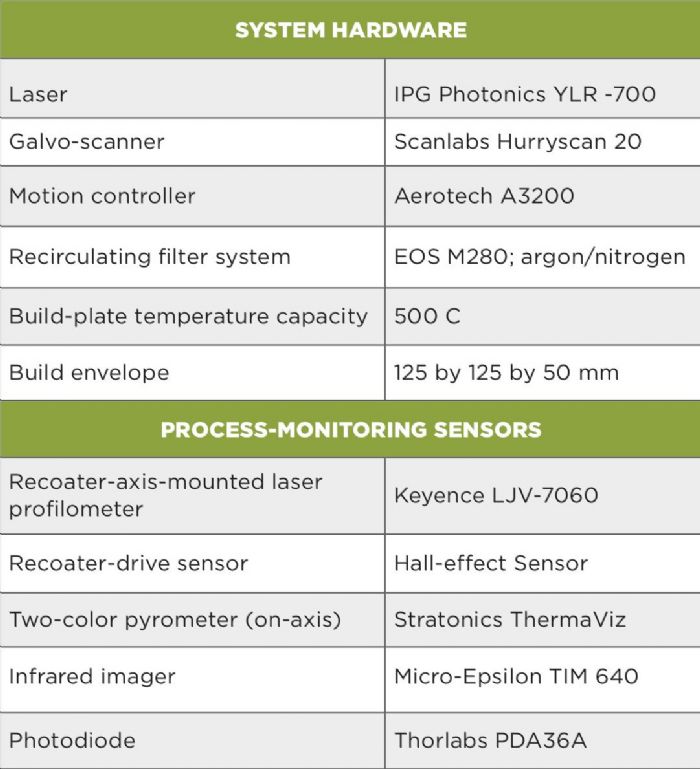

We conducted an investigation to compare and contrast the results of using stirred and linear-hatch techniques, as well as the effects of process-parameter changes (Fig. 2).We used test coupons from three conventional LPBF alloy systems: Type 316L stainless steel, Ti-6Al-4V and Inconel 718.

We conducted an investigation to compare and contrast the results of using stirred and linear-hatch techniques, as well as the effects of process-parameter changes (Fig. 2).We used test coupons from three conventional LPBF alloy systems: Type 316L stainless steel, Ti-6Al-4V and Inconel 718.

The powders were produced via inert-gas atomization, with the initial melt performed under a vacuum or inert-gas cover. Powders with particle-size range conforming to -325 Mesh/+10 μm (45/+10 μm) were purchased.

The powders were produced via inert-gas atomization, with the initial melt performed under a vacuum or inert-gas cover. Powders with particle-size range conforming to -325 Mesh/+10 μm (45/+10 μm) were purchased.

All builds were carried out on EWI’s open-architecture LPBF system (OAS), developed in 2016 as part of the Measurement Science Innovation Program for Additive Manufacturing, funded by NCDMM and NIST. A customizable LPBF test platform, it provides complete access to the hardware, optics and software overlays. As a result, the OAS offers unparalleled control of the path-planning variables, optical hardware, motion-control digital input for triggering and integration, on-and-off axis ports for sensor integration, and multiple sensor-mounting ports within the process chamber. Using the OAS, EWI has executed numerous government and commercially funded programs to correlate in-situ process-monitoring data with known quality metrics, and in this program, to demonstrate closed-loop process control.

All builds were carried out on EWI’s open-architecture LPBF system (OAS), developed in 2016 as part of the Measurement Science Innovation Program for Additive Manufacturing, funded by NCDMM and NIST. A customizable LPBF test platform, it provides complete access to the hardware, optics and software overlays. As a result, the OAS offers unparalleled control of the path-planning variables, optical hardware, motion-control digital input for triggering and integration, on-and-off axis ports for sensor integration, and multiple sensor-mounting ports within the process chamber. Using the OAS, EWI has executed numerous government and commercially funded programs to correlate in-situ process-monitoring data with known quality metrics, and in this program, to demonstrate closed-loop process control.

Process Parameters for Trials

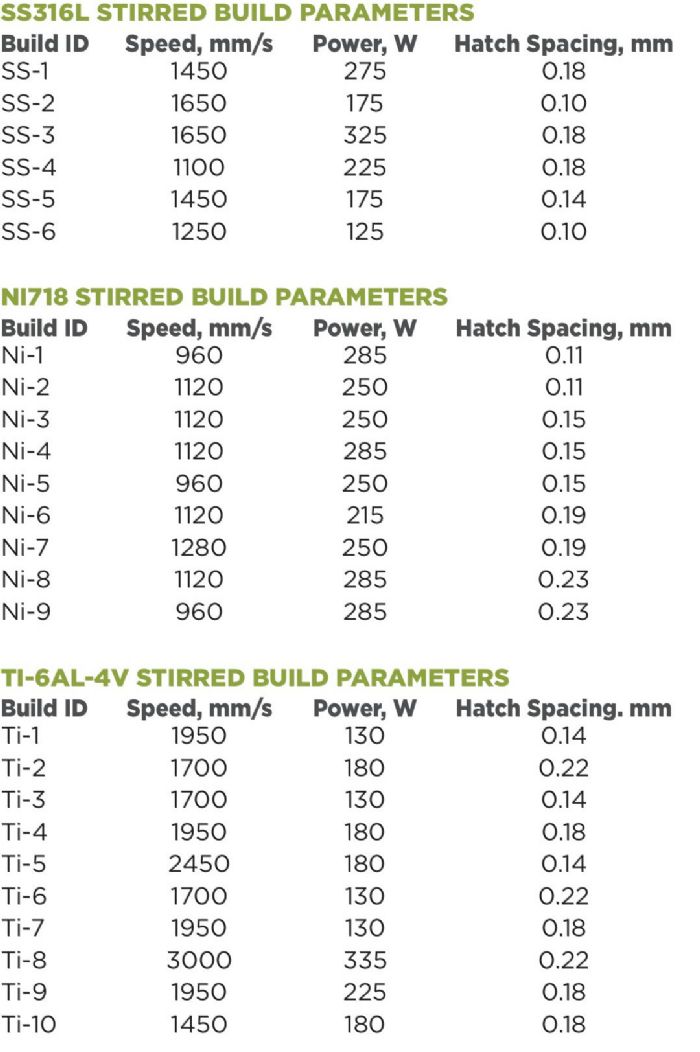

We employed a circular stirring pattern along with the laser parameters for the coupon trials (Fig. 3), which show, for Type 316L stainless steel, the typical as-built microstructure for linear hatching and variations in microstructure possible with stirred hatching. The stirred hatching builds to display larger grains, columnar grains, less-elongated grains and/or combinations of large and small grains, depending on the stirring parameters employed.

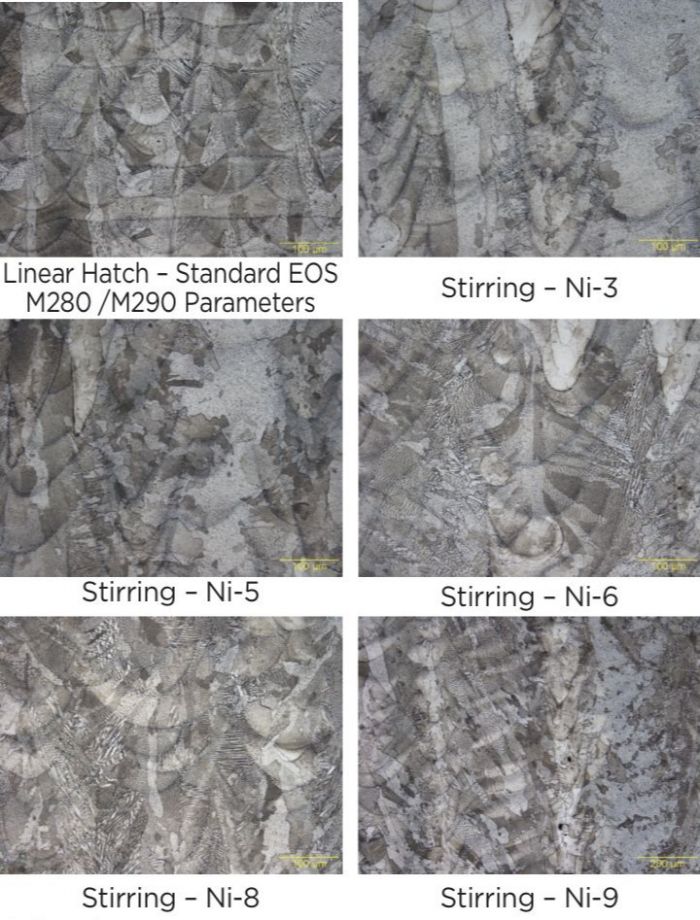

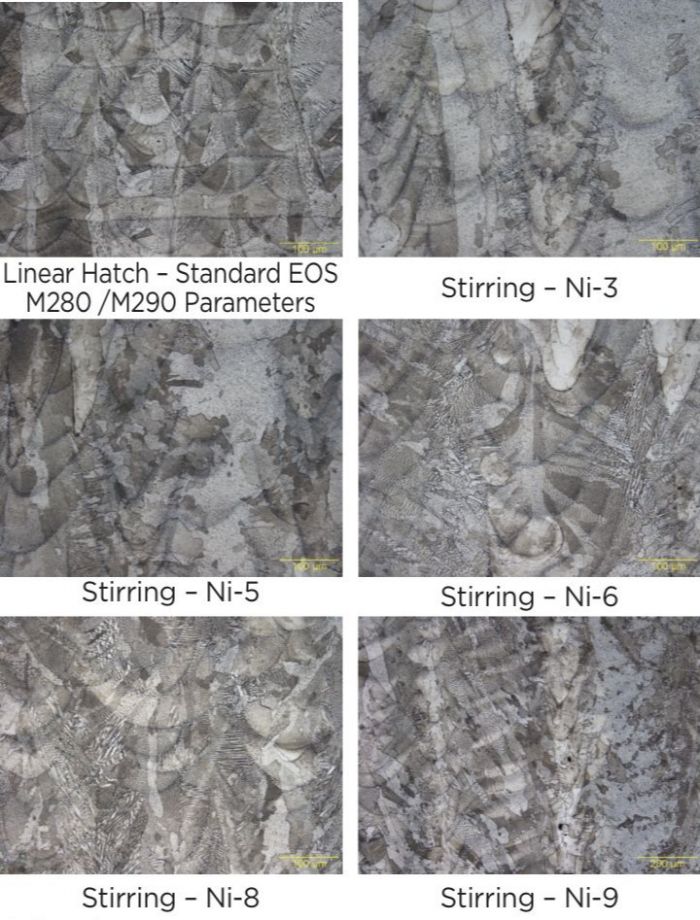

Fig. 4 shows the typical as-built microstructure for linear hatching and variations in microstructure possible with stirred hatching for Inconel 718. Grain refinement and the formation of necklace microstructure, containing both large and small grains, are apparent in the stirred hatching builds.

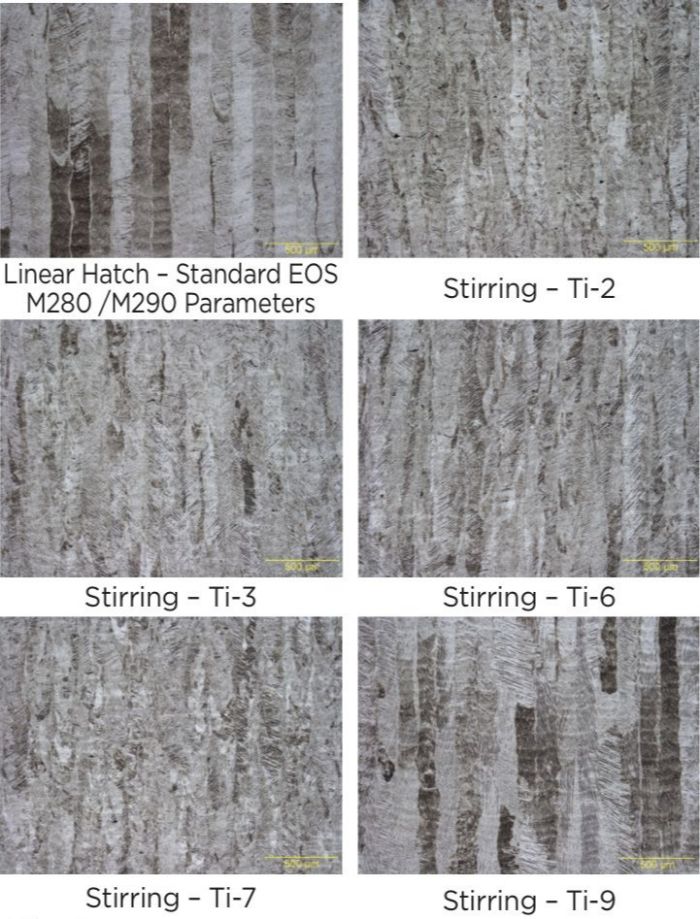

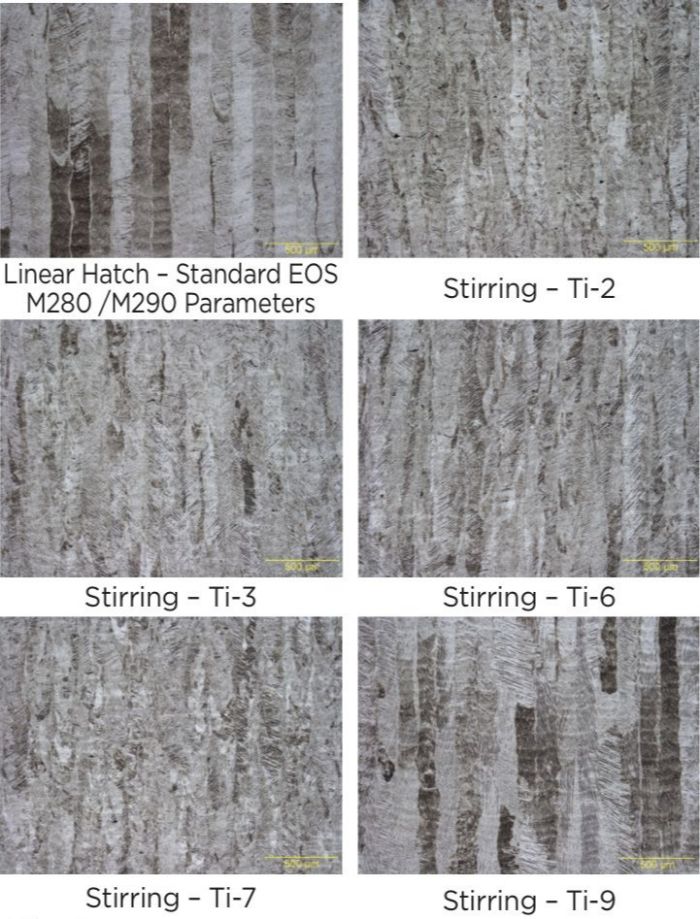

Fig. 5 shows the typical as-built microstructure for linear hatching and variations in microstructure possible with stirred hatching for Ti-6Al-4V.

Summary and Takeaways

As seen in the material studies, LPBF microstructures (the columnar microstructure visible in the linear hatched builds) can be coarsened or refined to various levels through the application of stirred hatch parameters. These positive results for three popular LPBF alloys show that laser-stirred hatching effectively can be used to tailor microstructure in 3D builds. Grain refinement, reduction of anisotropy and texture alteration are accomplished by laser stirring through balancing heat input, oscillation travel speed, linear travel speed and thermal-response time of the material being processed, to ensure that grains are broken up after partial processing solidification. The same factors can be tuned so that the stirred path mimics a larger-spot-size laser and the material sees slower cooling rates, resulting in grain coarsening.

EWI has developed more than 50 alloy systems for LPBF and can assist with rapid alloy development by leveraging state-of-the-art in-situ monitoring, machine learning and design-of-experiments techniques. We actively are looking for collaborations to explore using this laser-stirring technique to develop new materials and applications for LPBF. To discuss, please contact the author: asadek@ewi.org. 3DMP

See also: EWI, EOS of North America, Inc.

Technologies:

The most well-developed supply chain of all metal-AM processes, including service providers, and feedstock and equipment manufacturers

The most well-developed supply chain of all metal-AM processes, including service providers, and feedstock and equipment manufacturers These issues all can be addressed, in part by deliberately modifying the chemical composition of the alloy systems with the addition of trace elements, nucleating agents or even non-metallic reinforcement particles. While the chemistry-based solutions are gaining in popularity, they still must overcome the hurdles of material property allowable generation and qualification.

These issues all can be addressed, in part by deliberately modifying the chemical composition of the alloy systems with the addition of trace elements, nucleating agents or even non-metallic reinforcement particles. While the chemistry-based solutions are gaining in popularity, they still must overcome the hurdles of material property allowable generation and qualification.

Laser stirring has been adapted from electromagnetic arc stirring, a technique that combines the electromagnetic stirring of arc welds with electron-beam oscillation. This process has been shown to break up the dendritic microstructure of aluminum alloys, encourage an equiaxed grain structure, reduce thermal gradients at the edge of the melt pool and decrease mean grain size. Each of these attributes proves beneficial in reducing solidification cracking in high-strength aluminum alloys and austenitic stainless steels.

Laser stirring has been adapted from electromagnetic arc stirring, a technique that combines the electromagnetic stirring of arc welds with electron-beam oscillation. This process has been shown to break up the dendritic microstructure of aluminum alloys, encourage an equiaxed grain structure, reduce thermal gradients at the edge of the melt pool and decrease mean grain size. Each of these attributes proves beneficial in reducing solidification cracking in high-strength aluminum alloys and austenitic stainless steels.  We conducted an investigation to compare and contrast the results of using stirred and linear-hatch techniques, as well as the effects of process-parameter changes (Fig. 2).We used test coupons from three conventional LPBF alloy systems: Type 316L stainless steel, Ti-6Al-4V and Inconel 718.

We conducted an investigation to compare and contrast the results of using stirred and linear-hatch techniques, as well as the effects of process-parameter changes (Fig. 2).We used test coupons from three conventional LPBF alloy systems: Type 316L stainless steel, Ti-6Al-4V and Inconel 718.  The powders were produced via inert-gas atomization, with the initial melt performed under a vacuum or inert-gas cover. Powders with particle-size range conforming to -325 Mesh/+10 μm (45/+10 μm) were purchased.

The powders were produced via inert-gas atomization, with the initial melt performed under a vacuum or inert-gas cover. Powders with particle-size range conforming to -325 Mesh/+10 μm (45/+10 μm) were purchased. All builds were carried out on EWI’s open-architecture LPBF system (OAS), developed in 2016 as part of the Measurement Science Innovation Program for Additive Manufacturing, funded by NCDMM and NIST. A customizable LPBF test platform, it provides complete access to the hardware, optics and software overlays. As a result, the OAS offers unparalleled control of the path-planning variables, optical hardware, motion-control digital input for triggering and integration, on-and-off axis ports for sensor integration, and multiple sensor-mounting ports within the process chamber. Using the OAS, EWI has executed numerous government and commercially funded programs to correlate in-situ process-monitoring data with known quality metrics, and in this program, to demonstrate closed-loop process control.

All builds were carried out on EWI’s open-architecture LPBF system (OAS), developed in 2016 as part of the Measurement Science Innovation Program for Additive Manufacturing, funded by NCDMM and NIST. A customizable LPBF test platform, it provides complete access to the hardware, optics and software overlays. As a result, the OAS offers unparalleled control of the path-planning variables, optical hardware, motion-control digital input for triggering and integration, on-and-off axis ports for sensor integration, and multiple sensor-mounting ports within the process chamber. Using the OAS, EWI has executed numerous government and commercially funded programs to correlate in-situ process-monitoring data with known quality metrics, and in this program, to demonstrate closed-loop process control.

Video

Video