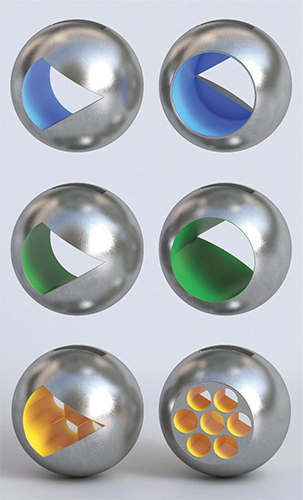

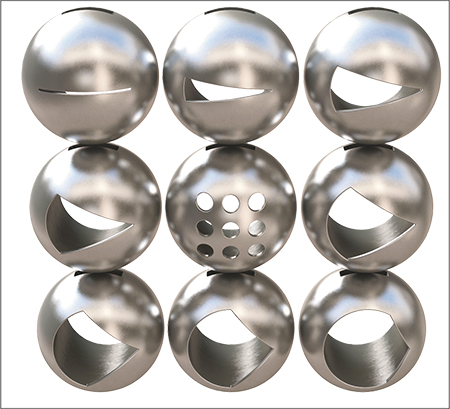

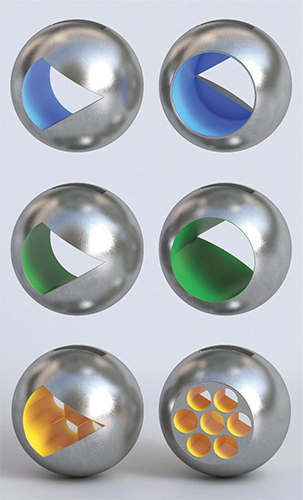

Currently manufactured via wire EDM (electric discharge machining), these balls are highly customizable, but also have limitations. Bray identified the potential to further increase the flow capacity of this product through AM, and to decrease the cavitation potential at the same time. To achieve this, two 3D-printed balls eliminate abrupt interruptions in the flow path, a consequence of traditional manufacturing methods, thus promoting laminar flow through the valve (Fig. 2). The smooth ball creates, between its full-port-opening side and the v-port side, a smooth transition, a feature not possible through standard CNC machining, while the honeycomb ball straightens flow through several internal pathways.

Designing for AM

The design process for AM parts contradicts that for traditionally machined components. When not limited by traditional manufacturing methods (e.g. mill, lathe, CNC), one can think about a valve from the “inside out” and consider the functional component of the design first, and the manufacturing or production method second.

The design process for AM parts contradicts that for traditionally machined components. When not limited by traditional manufacturing methods (e.g. mill, lathe, CNC), one can think about a valve from the “inside out” and consider the functional component of the design first, and the manufacturing or production method second.

Conventional design methodology, and most product-development processes, require the involvement of manufacturing engineers at the very early stages of design and throughout the design process. Designing for AM provides increased design freedoms and opens the doorway for innovation by allowing focus on functionality, not manufacturability. However, AM is not completely devoid of traditional processes and some post-processing may still be required. With respect to the design concepts developed in this project, these processes included grinding and polishing of the ball’s outer surface to achieve a suitable finish and create a tight seal.

Adapting for AM

Adapting design methodology for AM requires consideration of print setup, part removal and post-processing, all part of this project’s evolution.

Adapting design methodology for AM requires consideration of print setup, part removal and post-processing, all part of this project’s evolution.

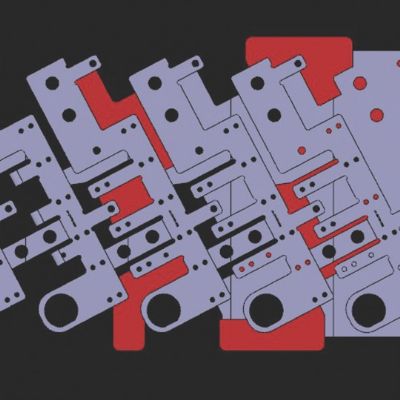

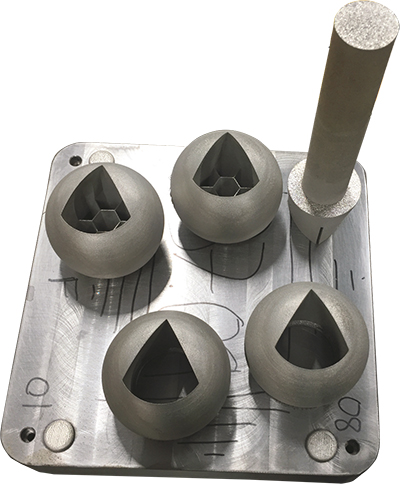

During print setup, identifying proper support-material placement is critical to the quality of the build. Bray’s ball-valve models needed slight adjustments to ensure sufficient adhesion to the build plate, as well as suitable support throughout the height of the build. Build orientation also was considered and carefully selected to reduce required supports and maximize build efficiency. Finally, the overall layout of parts on the build platform, assigned to minimize heat-transfer effects of nearby parts, optimized build times and avoided part drag during the re-coat process (Fig. 3).

Another critical consideration, part removal may require a slight adaptation in AM design. Unlike some plastic printers that create dissolvable or breakaway support material, metal-AM components typically are “welded” to a build plate, requiring physical removal. Renishaw accomplishes this through locator buttons 3D printed directly on the build platform, indicating precisely where to separate the print using a wire EDM. Furthermore, Bray’s ball valves require the addition of surplus geometry into the design in order to assist with accurate part removal. Removal of excess powder is another consideration for AM designers, especially when dealing with internal lattice-like structures aimed at reducing weight.

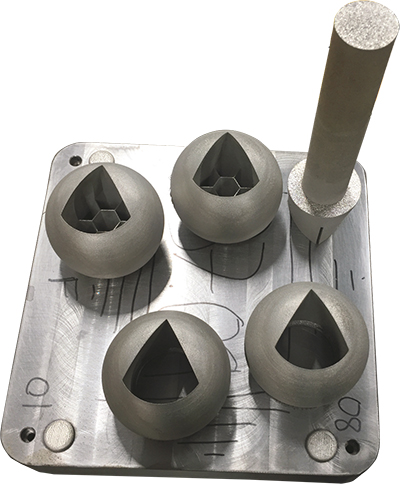

Typically, parts produced by a metal 3D printer require some level of post-processing that can range from simple support removal to complex CNC machining. Again, Bray’s 3D-printed ball valves required polishing and grinding to achieve an acceptable surface finish for creating a tight seal. Two main design adaptations were required to enable this post-processing operation. First, excess material needed to be added to the outer diameter, similar to adding machining stock to a sand casting. Second, securing these components during grinding and polishing required custom fixtures. Due to the complex flow-bore geometry of these valve balls, a simple cylindrical expanding mandrel no longer would suffice. The solution: 3D print the required custom mandrels as well. Bray and Renishaw did that, applying the same design and AM principles to the mandrels as were applied to the valve balls themselves.

Maximizing Performance

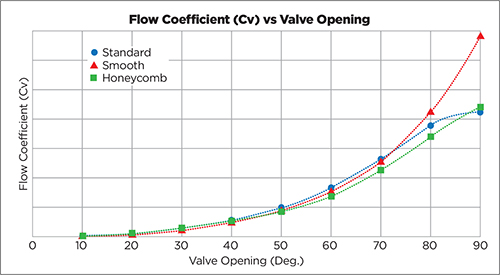

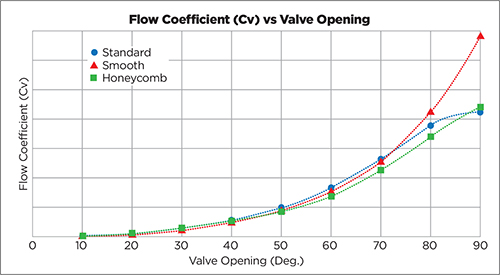

Metal 3D printers offer a unique benefit: the ability to produce functional end-use parts that are heated, cooled, machined, pressurized and tested in the same manner as a part produced by traditional metalforming methods (sand casting, investment casting, forging, etc.). Weeks, even months, can be saved in the product-development process by conducting prototype qualification on metal-AM components. In order to realize this benefit, Bray assembled the AM components into standard ball valves and subjected them to prototype validation testing—specifically flow-coefficient and cavitation-index evaluation. The test results, partially shown in Fig. 4, confirmed the added performance benefits on one of the design concepts. The smooth-transition ball resulted in a 62-percent increase of flow capacity through the valve at full opening, as compared to the standard V-port ball valve.

Metal 3D printers offer a unique benefit: the ability to produce functional end-use parts that are heated, cooled, machined, pressurized and tested in the same manner as a part produced by traditional metalforming methods (sand casting, investment casting, forging, etc.). Weeks, even months, can be saved in the product-development process by conducting prototype qualification on metal-AM components. In order to realize this benefit, Bray assembled the AM components into standard ball valves and subjected them to prototype validation testing—specifically flow-coefficient and cavitation-index evaluation. The test results, partially shown in Fig. 4, confirmed the added performance benefits on one of the design concepts. The smooth-transition ball resulted in a 62-percent increase of flow capacity through the valve at full opening, as compared to the standard V-port ball valve.

Additionally, this valve also exhibited better cavitation performance. The honeycomb ball did demonstrate an increased flow capacity—about 4 percent at full opening—but that trend was not consistent through the full stroke of the valve. The cavitation performance of this valve was indecisive as improvements were noted, but not consistently throughout the valve stroke.

Conclusions

Metal AM no longer is a technology reserved for academic research facilities and extremely specialized industries, though it may be underutilized. Specific to the valve industry, metal AM creates a pathway toward innovative solutions to common performance desires such as higher flow capacities and decreased cavitation likelihood, as demonstrated through Bray and Renishaw’s case study.

Furthermore, metal AM can dramatically reduce functional-prototype lead times and speed the product-development process, resulting in faster time-to-market for new products. As long as proper design for AM and adapt-for-AM principles are applied, the valve industry can experience thriving innovation resulting in performance gains once thought impossible. 3DMP

This is an edited version of an article published on ValveMagazine.com, reprinted with the permission of the Valve Manufacturers Association, www.vma.org.

See also: Renishaw Inc.

Technologies:

The emergence of severe service valves, smart monitoring systems and highly engineered control products are advancing the traditionally conservative valve industry, with metal additive manufacturing (AM) playing a greater role in new-product development.

The emergence of severe service valves, smart monitoring systems and highly engineered control products are advancing the traditionally conservative valve industry, with metal additive manufacturing (AM) playing a greater role in new-product development.

The design process for AM parts contradicts that for traditionally machined components. When not limited by traditional manufacturing methods (e.g. mill, lathe, CNC), one can think about a valve from the “inside out” and consider the functional component of the design first, and the manufacturing or production method second.

The design process for AM parts contradicts that for traditionally machined components. When not limited by traditional manufacturing methods (e.g. mill, lathe, CNC), one can think about a valve from the “inside out” and consider the functional component of the design first, and the manufacturing or production method second.  Adapting design methodology for AM requires consideration of print setup, part removal and post-processing, all part of this project’s evolution.

Adapting design methodology for AM requires consideration of print setup, part removal and post-processing, all part of this project’s evolution. Metal 3D printers offer a unique benefit: the ability to produce functional end-use parts that are heated, cooled, machined, pressurized and tested in the same manner as a part produced by traditional metalforming methods (sand casting, investment casting, forging, etc.). Weeks, even months, can be saved in the product-development process by conducting prototype qualification on metal-AM components. In order to realize this benefit, Bray assembled the AM components into standard ball valves and subjected them to prototype validation testing—specifically flow-coefficient and cavitation-index evaluation. The test results, partially shown in Fig. 4, confirmed the added performance benefits on one of the design concepts. The smooth-transition ball resulted in a 62-percent increase of flow capacity through the valve at full opening, as compared to the standard V-port ball valve.

Metal 3D printers offer a unique benefit: the ability to produce functional end-use parts that are heated, cooled, machined, pressurized and tested in the same manner as a part produced by traditional metalforming methods (sand casting, investment casting, forging, etc.). Weeks, even months, can be saved in the product-development process by conducting prototype qualification on metal-AM components. In order to realize this benefit, Bray assembled the AM components into standard ball valves and subjected them to prototype validation testing—specifically flow-coefficient and cavitation-index evaluation. The test results, partially shown in Fig. 4, confirmed the added performance benefits on one of the design concepts. The smooth-transition ball resulted in a 62-percent increase of flow capacity through the valve at full opening, as compared to the standard V-port ball valve.